Kā tiek ražota oglekļa šķiedra: no izejvielām līdz galaproduktam

Problēma: oglekļa šķiedru var būt grūti iegūt pareizi

Vai jums vajag stipras daļas kas nesver daudz? Daudzi uzņēmumi to dara. Bet labu oglekļa šķiedras detaļu izgatavošana nav vienkārša.

Kāpēc tas ir grūti:

- Jums ir nepieciešami īpaši instrumenti

- Procesam ir daudz soļu

- Kļūdas var sabojāt visu daļu

- Daudziem ražotājiem trūkst pieredzes

Sāpes kļūst stiprākas

Kad oglekļa šķiedra noiet greizi, tā maksā jums naudu. Sliktās daļas nozīmē:

- Jūsu produkti neiztur testus

- Klienti kļūst dusmīgi

- Jūs izšķērdējat materiālus

- Projekti kavējas

- Jūs zaudējat naudu

Izmantojot parastos uzņēmumus, jūs varat iegūt tādas detaļas izskaties labi bet viegli salūzt. Vai arī tie var būt pārāk smagi. Vai arī pārāk dārgi. Tas padara jūsu darbu grūtāku.

Risinājums: 28+ gadu zināšanas par oglekļa šķiedru

Labas ziņas! Mūsu Ķīnas rūpnīca ir izgatavojusi oglekļa šķiedras detaļas 28+ gadi. Mēs zinām visus trikus, kā padarīt detaļas, kas darbojas lieliski. Mēs varam palīdzēt jums izgatavot jebkuru oglekļa šķiedras lietu, kas jums nepieciešama.

Mēs atvieglojam jūsu dzīvi:

- Pielāgotu detaļu izgatavošana tieši jums

- Izmantojot labāko oglekļa šķiedru

- Pārbauda visu

- Ātra piegāde

- Zemu izmaksu uzturēšana

Kā tiek izgatavota oglekļa šķiedra: galvenie soļi

Paskatīsimies, kā mēs pārvēršam vienkāršu materiālus pārsteidzošā oglekļa šķiedrā produkti!

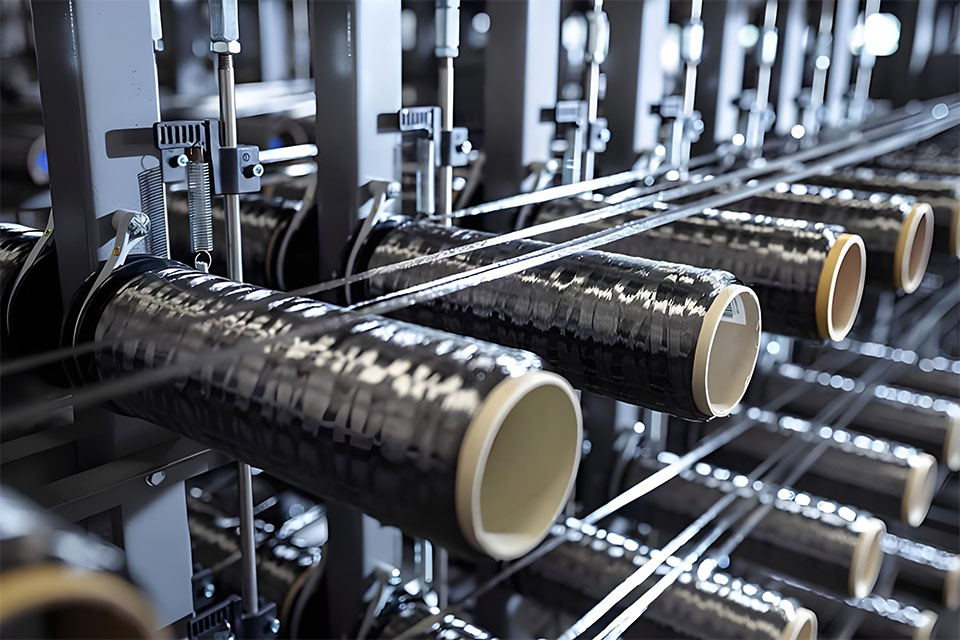

1. darbība. Mēs sākam ar labiem materiāliem

Mēs sākam ar īpašām stīgām, ko sauc prekursori. Labākais veids ir PAN (poliakrilnitrils). Daži citi veidi ir:

- Lignīns (nāk no augiem)

- Piķis (nāk no eļļas)

- Rayon (tagad retāk)

2. darbība. Mēs sasildām stīgas, lai padarītu tās stipras

Stīgas iziet cauri lielām krāsnīm, veicot šādas darbības:

- Stabilizācija: Mēs karsējam stīgas gaisā (200-300°C)

- Karbonizācija: Mēs tos karsējam daudz karstāk (1000-3000°C) bez gaisa

- Virsmas apstrāde: Mēs padarām virsmu raupju, lai līme labāk pielīp

- Izmēru noteikšana: Mēs pievienojam plānu kārtu, lai aizsargātu šķiedras

| Procesa solis | Temperatūra | Kas notiek | Kāpēc tas ir svarīgi |

|---|---|---|---|

| Stabilizācija | 200-300°C | Stīgas kļūst melnas un nekūst | Padara tos gatavus lielam karstumam |

| Karbonizācija | 1000-3000°C | Atstāj bezoglekļa atomi | Izveido īpaši spēcīgas oglekļa stīgas |

| Virsmas apstrāde | Telpas temp | Uz virsmas ir nelieli raupji plankumi | Palīdz labāk pielipt līmei |

| Izmēru noteikšana | Telpas temp | Pievienots plāns mētelis | Aizsargā šķiedras nākamo darbību laikā |

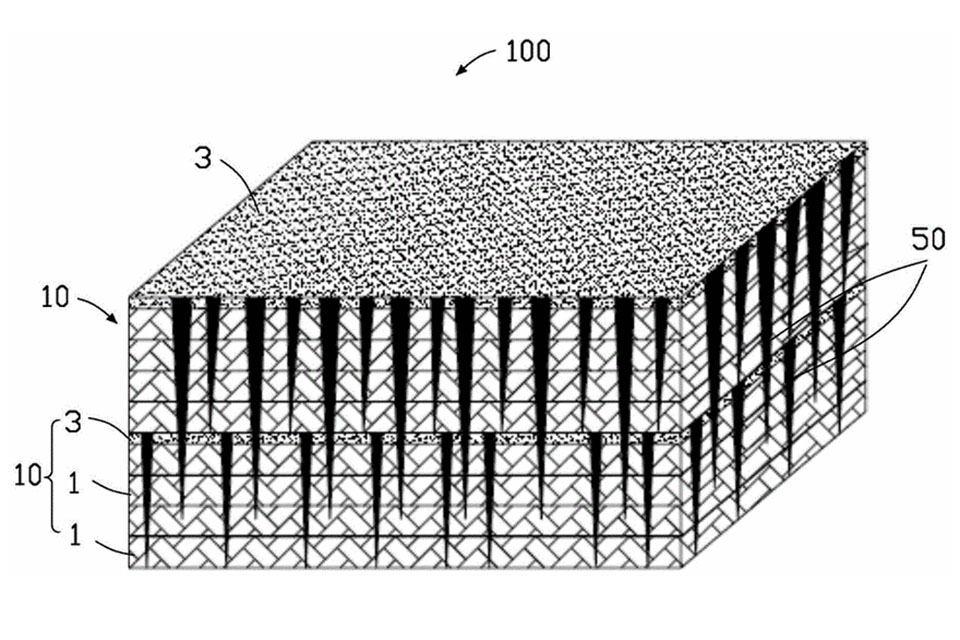

3. darbība. Mēs pārvēršam oglekļa šķiedru par noderīgām lietām

Tagad jautrākā daļa! Mēs ņemam šīs oglekļa virtenes un veidojam produktus:

- Mēs ievietojam šķiedras īpašos modeļos

- Mēs pievienojam sveķus (piemēram, īpašu līmi)

- Mēs to visu saspiežam kopā

- Mēs to izārstējam (ļaujiet tam kļūt cietam)

- Mēs pabeidzam virsmu, lai tā izskatās jauki

Jauni veidi, kā uzlabot oglekļa šķiedru

Gudri cilvēki atrod labākus veidus, kā iegūt oglekļa šķiedru. Mūsu rūpnīca seko visām šīm jaunajām idejām!

Mazāks enerģijas patēriņš

Vecais oglekļa šķiedras ražošanas veids patērē daudz enerģijas. Jauni veidi to novērš 70%!

- CARBOWAVE projekts izmanto mikroviļņu krāsnis lielo cepeškrāsns vietā

- Tas ietaupa enerģiju un naudu

- Oglekļa šķiedra ir tikpat spēcīga

Zemei draudzīgi materiāli

Zinātnieki tagad izmanto augu materiāli eļļas vietā:

- Lignīns (no papīra ražošanas) samazina oglekļa piesārņojumu par 16.3%

- Zaļā elektrība nodrošina dažas rūpnīcas

- Pārstrādāta oglekļa šķiedra dod vecajām daļām jaunu dzīvi

Kāpēc mūsu 28+ gadu pieredze jums ir svarīga

Strādājot ar mums, jūs iegūstat visas mūsu zināšanas. Tas nozīmē:

- Mazāk atkritumu – Mēs labi protam izmantot materiālus

- Labāka kvalitāte – Mēs pamanām problēmas, pirms tās rodas

- Zemākas izmaksas – Mūsu process ir ļoti efektīvs

- Ātrāka piegāde – Nav nepieciešami nekādi pasākumi

- Laimīgi klienti - Jūsu produkti darbojas pareizi pirmajā reizē

Mēs varam palīdzēt ar oglekļa šķiedru izmantošanu

Mēs izgatavojam detaļas daudzām lietām. Šeit ir daži lielie:

Automašīnas un sacīkstes

Mēs izgatavojam oglekļa šķiedras auto daļas, kas ir viegls un stiprs. Pat F1 sacensību komandas izmanto oglekļa šķiedru! Mercedes-AMG savās 2025. gada F1 automašīnās izmantos zaļo oglekļa šķiedru.

Izgatavojam auto detaļas:

- Kapuces

- Spoileri

- Informācijas paneļi

- Sacīkšu sēdekļi

- Pilna ķermeņa komplekti

Motocikli un sports

Oglekļa šķiedras motocikls daļas izskatās forši un darbojas lieliski. Tie palīdz velosipēdiem braukt ātrāk ar mazāku degvielas patēriņu.

Populārākās motociklu daļas:

- Gāzes tvertnes

- Spārni

- Sānu paneļi

- Priekšējie stikli

- Izplūdes vāki

Vēja enerģija un tīra enerģija

Vēja parkiem ir nepieciešami lieli, spēcīgi lāpstiņas. Tos veido oglekļa šķiedra 15-20% efektīvāka.

Izgatavojam arī detaļas priekš:

- Saules paneļu rāmji

- Ūdeņraža tvertnes

- Akumulatoru kastes

- Kodolenerģijas sistēmas

Pielāgota oglekļa šķiedra: radīta tieši jums

Vajag kaut ko īpašu? Mūsu pielāgota oglekļa šķiedra pakalpojums palīdz jums izveidot visu, ko vien varat iedomāties!

Kā darbojas mūsu pielāgotais process:

- Jūs pastāstiet mums, kas jums nepieciešams

- Kopā veidojam dizainu

- Mēs veidojam testa daļu

- Jūs to pārbaudiet un lūdzat izmaiņas

- Mēs izgatavojam jūsu pēdējās daļas

Kāpēc mūsu rūpnīca pārspēj pārējos

Ne visi oglekļa šķiedras ražotāji ir vienādi. Mūsu 28+ gadu darbs ir redzams katrā daļā. Lūk, kāpēc cilvēki mūs izvēlas:

Labāki materiāli

Mēs izmantojam labāko oglekļa šķiedru ar pareizām īpašībām:

- 36K starpmodulis augsta sprieguma daļām

- Šķiedras uz PAN bāzes lielākajai daļai produktu

- Īpaši pinumi dažādām vajadzībām

Jauni rīki un metodes

Mēs paliekam moderni, izmantojot labākos rīkus:

- Automatizēts izkārtojums ideālam šķiedru izvietojumam

- Datoru testēšana lai atrastu vājās vietas

- Īpašas konservēšanas krāsnis perfektiem rezultātiem

Zemei draudzīgas iespējas

Mums rūp planēta:

- Pārstrādāta oglekļa šķiedra iespējas

- Mazāk atkritumu mūsu procesā

- Enerģijas taupīšana metodes

Vienkārša mūsu pakalpojumu tabula

| Serviss | Ko mēs darām | Kāpēc tas jums palīdz |

|---|---|---|

| Dizaina palīdzība | Mēs palīdzam īstenot jūsu ideju | Ietaupa jūsu laiku un novērš problēmas |

| Ātri paraugi | Mēs ātri izgatavojam testa daļas | Jūs varat pārbaudīt pirms pilnīgas ražošanas |

| Pielāgotas veidnes | Mēs izgatavojam veidnes tieši jums | Jūsu daļas ir ideāli piemērotas |

| Kvalitātes testi | Mēs pārbaudām katru daļu | Nav sliktu pārsteigumu |

| Mazas partijas | Mēs varam izgatavot tikai dažas detaļas | Piemērots īpašiem projektiem |

| Liela ražošana | Mēs izgatavojam tūkstošiem detaļu | Piemērots lieliem uzņēmumiem |

Vai esat gatavs izveidot kaut ko lielisku?

Strādājot ar mums, jūs saņemat:

- 28+ gadi pieredze ar oglekļa šķiedru

- Pielāgotas detaļas radīts tieši tev

- Augstākā kvalitāte kas ilgst

- Ātra piegāde lai jūs ievērotu grafiku

- Godīgas cenas kas palīdz jūsu budžetam

Neļaujiet oglekļa šķiedras problēmām jūs bremzēt! Mūsu rūpnīcā ir vajadzīgās atbildes.

Apmeklējiet mūsu galveno vietni vietnē oglekļa šķiedra lai redzētu vairāk par to, ko mēs varam darīt!

Sazinieties ar mums jau šodien!

E-pasts: [email protected] Tālrunis: +86-136 2619 1009 WeChat: ChinaCarbonFibers

Piepildīsim jūsu sapņus par oglekļa šķiedru!