Carbon Fiberglass Composite: A Practical, Engineering-Level Guide

Carbon fiberglass composites are not a marketing buzzword—they are a deliberate engineering solution to a problem designers face every day: how to balance stiffness, strength, impact resistance, weight, manufacturability, and cost within a single structure.

Unlike pure carbon fiber or pure fiberglass laminates, carbon fiberglass composites combine two fundamentally different reinforcement behaviors inside a shared polymer matrix. When designed correctly, the result is not a compromise, but a better-balanced material system—one commonly developed and supplied by experienced oglekļa kompozītu ražotāji working across aerospace and automotive programs .

This is why hybrid carbon–glass composites continue to expand across aerospace, automotive, marine, sporting goods, and industrial applications.

What Is a Carbon Fiberglass Composite?

A carbon fiberglass composite is a hybrid fiber-reinforced polymer (FRP) in which carbon fiber and glass fiber are intentionally combined within a resin matrix.

Each constituent serves a distinct purpose:

- Oglekļa šķiedra contributes high tensile strength, high stiffness, and low density

- Stikla šķiedra contributes impact resistance, fracture toughness, and cost efficiency

- The polymer matrix binds the fibers, transfers load, and protects them from environmental damage

Rather than asking “Which fiber is better?”, hybrid composites ask a more useful question: “Where does each fiber perform best within the structure?”

This philosophy underpins most modern pasūtījuma kompozītmateriālu rūpnīca workflows, where material choice follows load paths rather than marketing labels .

Composite Fundamentals (Why Hybrids Work)

What Makes a Material a Composite?

A composite material is defined by the interaction between reinforcement and matrix, not by either component alone.

- Fibers carry most of the mechanical load

- The matrix distributes stresses, maintains fiber alignment, and resists environmental attack

Together, they form polymer matrix composites (PMCs) whose properties can be tailored far beyond those of conventional plastics or metals.

Carbon Fiber: Strength and Stiffness Where It Matters

Carbon Fiber Reinforced Polymer (CFRP) is valued for its:

- Very high tensile strength and flexural modulus

- Excellent fatigue resistance

- Low density and minimal creep

- Strong corrosion resistance

However, carbon fiber is anisotropic and relatively brittle under impact. These characteristics make it ideal for stiffness-critical load paths—but less forgiving in damage-prone areas such as exposed exterior panels on oglekļa šķiedras automašīnas and motorsport structures .

Fiberglass: Toughness, Damage Tolerance, and Cost Control

Glass Fiber Reinforced Polymer (GFRP) behaves very differently:

- Higher impact resistance and fracture toughness

- Better energy absorption before failure

- Lower material and processing cost

- Greater tolerance to manufacturing variability

For these reasons, fiberglass remains dominant in marine structures, industrial parts, and protective layers, even in high-performance systems that also incorporate pielāgota oglekļa šķiedra reinforcement .

Why Engineers Combine Carbon Fiber and Fiberglass

A carbon fiberglass composite—also known as a hybrid composite—is designed to place each fiber where it performs best.

In practice, this material optimization is typically implemented through custom carbon fiber parts manufacturing , where laminate architecture, fiber placement, and resin systems are engineered specifically for each application.

Typical hybrid strategies include:

- Carbon fiber in primary load directions

- Fiberglass in outer plies for impact resistance

- Glass fiber layers to reduce crack propagation and delamination

- Selective fiber placement to reduce overall laminate cost

The result is a laminate that often outperforms pure CFRP in real-world service, especially where impacts, vibration, or fatigue are involved.

Material Structure and Laminate Design

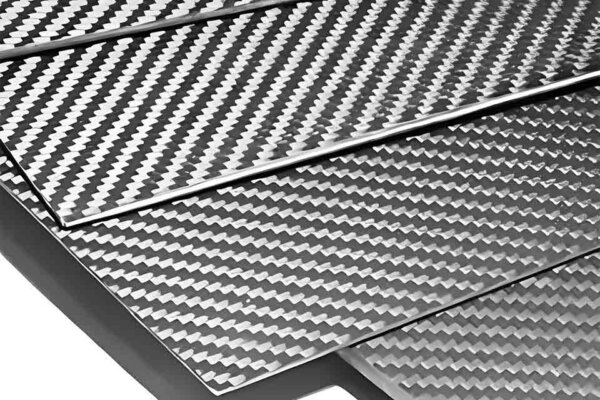

Fiber Forms and Reinforcement Fabrics

Hybrid laminates use a wide range of reinforcement architectures, including:

- Unidirectional fibers and tapes for stiffness

- Woven, biaxial, and triaxial fabrics for multi-directional load control

- Chopped strand mat for surface conformity and isotropy

- Hybrid fabrics that interweave carbon and glass fibers

These layers are stacked into a composite laminate, where sequence and orientation matter as much as material choice.

Laminate Layup and Stacking Sequence

Key design variables include:

- Ply orientation angles

- Quasi-isotropic vs directionally optimized layouts

- Fiber volume fraction

- Interlaminar shear performance

Poor laminate design—not material choice—is the most common cause of delamination, premature fatigue failure, and low impact tolerance, especially in poorly controlled outsourced production.

Resin Systems and Composite Chemistry

Common Resin Choices

Most carbon fiberglass composites rely on thermoset resin systems, tostarp:

- Epoksīda sveķi for high structural performance

- Vinyl ester resin for chemical resistance and toughness

- Poliestera sveķi for cost-sensitive applications

The resin must be compatible with both fiber types and the selected manufacturing process—something experienced composite suppliers validate early in development.

Why Resin Behavior Matters

Critical resin parameters include:

- Glass transition temperature (Tg)

- Cure kinetics and cure-cycle optimization

- Thermal expansion compatibility with fibers

Proper resin wet-out and controlled curing reduce voids, improve fiber bonding, and stabilize long-term performance.

Manufacturing Processes and Their Impact

Carbon fiberglass composites can be manufactured using multiple methods, each with different cost and quality implications:

- Hand lay-up and vacuum bagging for flexibility

- Vacuum infusion and RTM for consistency and scalability

- Compression molding and pultrusion for high-volume parts

- Prepreg layup with autoclave curing for aerospace-grade performance

Process selection directly affects fiber volume fraction, surface finish, repeatability, and inspection requirements, which is why many projects rely on vertically integrated oglekļa kompozītu ražotāji rather than generic suppliers.

Sandwich Structures and Energy Absorption

Many hybrid composites are built as sandwich structures, where thin composite skins are bonded to lightweight core materials.

Common core options include:

- Foam cores

- Honeycomb core materials

This architecture dramatically increases bending stiffness and crash energy absorption without significant weight gain, making it ideal for transportation and marine structures.

This sandwich architecture is also widely applied in automotive safety components such as carbon fiber bucket seats, where hybrid laminates help manage impact loads, improve energy absorption, and maintain structural integrity during crashes.

Mechanical and Physical Performance

Key Mechanical Characteristics

Well-designed carbon fiberglass composites typically offer:

- High tensile and flexural strength

- Improved impact resistance versus pure CFRP

- Controlled anisotropic behavior

- Better damage tolerance under real-world loading

Performance Observations from Studies

Published studies consistently show that hybrid laminates can deliver:

- Significant cost reduction versus full carbon

- Substantially higher impact resistance

- Comparable stiffness for many structural applications

These gains come from architecture and process control, not marketing claims.

Carbon Fiber vs Fiberglass vs Hybrid: A Practical Comparison

| Funkcija | Oglekļa šķiedra | Stikla šķiedra | Hybrid Composite |

|---|---|---|---|

| Strength-to-weight | Ļoti augsts | Mērens | Augsts |

| Triecienizturība | Nolaist | Augsts | Augsts |

| Izmaksas | Augsts | Zems | Vidēja |

| Best use | Stiffness-critical | Toughness-critical | Balanced systems |

For many applications, hybrid composites represent the most rational engineering choice—not a compromise.

Testing, Quality Control, and Certification

Structural composites require verification, not assumptions.

Common validation methods include:

- Mechanical test methods

- Ultrasonic non-destructive inspection

- Digital Image Correlation

- Finite Element Analysis (FEA) correlation

Compliance with ASTM and ISO composite standards is essential in aerospace and automotive programs.

Applications Across Industries

Carbon fiberglass composites are widely used in:

- Aerospace structures and control surfaces

- Automotive composite panels and tubes

- Marine hulls and sandwich decks

- Sporting goods and industrial components

Beyond large structural components, hybrid carbon–glass composites are increasingly applied in lightweight, impact-sensitive systems where stiffness, vibration damping, and durability must be carefully balanced.

In marine and water sports applications, a typical example is carbon fiber gasoline surfboards. In these structures, carbon fiber provides global stiffness and weight reduction, while fiberglass layers improve impact tolerance, vibration damping, and resistance to localized damage caused by water impact and operational loads.

Learn more about our oglekļa šķiedras benzīna sērfinga dēlis.

Similar hybrid laminate strategies are also widely adopted in unmanned aerial vehicles (UAVs), where controlled stiffness, impact resistance, and fatigue performance are critical for airframes, arms, and protective shells—an approach commonly seen in advanced carbon fiber drone structures.

Their appeal lies in predictable performance under real service conditions, not just laboratory strength numbers.

Sustainability and Future Direction

The industry is actively addressing sustainability through:

- Composite recycling initiatives

- Recycled carbon fiber usage

- Biocomposite development

- Improved fire-retardant composite systems

Hybrid designs often support sustainability goals by reducing carbon fiber content without sacrificing performance, particularly in large-scale industrial programs.

Secinājums

A carbon fiberglass composite is not simply “carbon plus glass.” It is a designed material system, optimized through fiber selection, laminate architecture, resin chemistry, and manufacturing control.

When engineered correctly, hybrid composites offer:

- Strong mechanical performance

- Improved impact resistance

- Lower cost than full carbon systems

- Broad applicability across demanding industries

This balance ensures that carbon fiberglass composites will remain a core material strategy in advanced engineering for years to come.