Laipni lūgti mūsu pielāgota oglekļa šķiedra produkti! Mēs ražojam stiprs, gaisma caurules un stieņi dažādiem lietojumiem. Mūsu ogleklis šķiedras caurules ir labākā izvēle uzņēmumiem kam nepieciešamas augšējās daļas. Mēs ražojam produktus automašīnām, lidmašīnām, sporta rīkiem, medicīnas instrumentiem, ēkām un daudz kam citam!

Kāpēc izvēlēties mūsu oglekļa šķiedras caurules? Tas ir ļoti spēcīga bet ļoti viegls. Tas nerūsē. Tā kalpo ilgu laiku. Mēs varam izgatavot jebkuru izmērs, forma, vai pabeigt jums nepieciešams. Mūsu caurules lieliski darbojas visdažādākajās vietās.

Kāpēc pasūtīt pie mums?

- Mēs izgatavojam pielāgotie izmēri tieši tev

- Mēs izmantojam tikai augstākās kvalitātes oglekļa šķiedra

- Mēs ražojam caurules jau vairāk nekā 15 gadus.

- Mēs sūtām uz uzņēmumiem visā pasaulē

- Mēs piedāvājam labas cenas lieliem pasūtījumiem

Oglekļa šķiedras cauruļu veidi - atrodiet savu ideālo risinājumu

Mēs ražojam divu veidu oglekļa šķiedras caurules: roll iesaiņots un pulverizēts ogleklis caurules. Katram veidam ir labas īpašības. Labākā ir atkarīga no tā, kādam nolūkam tā ir nepieciešama.

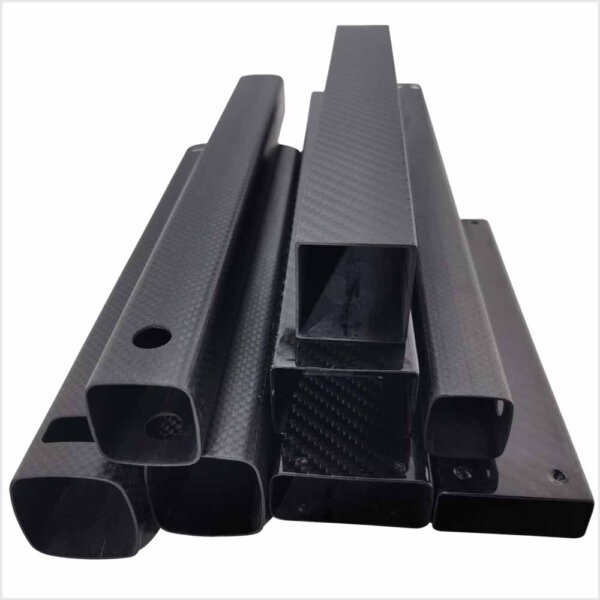

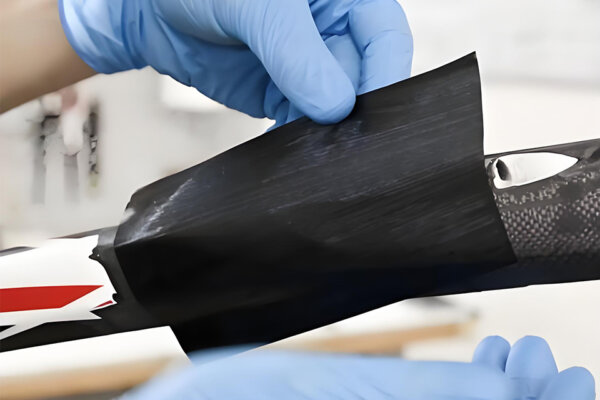

Rullītis ietīta oglekļa šķiedra caurules tiek izgatavotas, ievietojot oglekļa šķiedra loksnes ap rīku, ko sauc par serdeņi. Mēs varam izgatavot ne tikai apaļas, bet arī dažādu formu caurules. Tās var būt kvadrātveida, taisnstūravai pat īpašas formas, piem. aerodinamiskā plātne. Šīm caurulēm ir ļoti labas spēks visos veidos. Tie labi darbojas aviācija daļas, sporta inventāru un automašīnu daļas.

Pultruded carbon fiber tubes are made in a different way. We pull the oglekļa šķiedra caur karstu presformu. Tādējādi tiek izgatavotas caurules, kas ir ļoti izturīgas vienā virzienā. Pultrūdēta apaļa caurules ir ideāli piemērotas, ja jums ir nepieciešams kaut kas ļoti stīvs bet tomēr gaisma. Tie ir noderīgi stabss, automašīnu detaļas un rūpnieciskā instrumenti. Mūsu inženieriss var palīdzēt izvēlēties pareizo cauruli darbam.

| Tips | Labākais priekš | Formas | Pabeigšanas opcijas |

|---|

| Rullī iesaiņots | Visaptveroša izturība | Apaļa, kvadrātveida, taisnstūra, pielāgota | Matēts, glancēts, krāsots |

| Pultrūdēts ogleklis | Maksimālais stingrums | Apaļš, kvadrātveida | Slīpēts, matēts, glancēts |

"Mēs pārgājām uz oglekļa šķiedras caurulēm saviem dronu rāmjiem un redzējām, ka 30% svars samazinājās, bet izturība uzlabojās. Šīs caurules ir mainījušas mūsu produktu kvalitāti." - Lielākais dronu ražotājs

Pielāgota apdare un izmēri atbilstoši jūsu vajadzībām

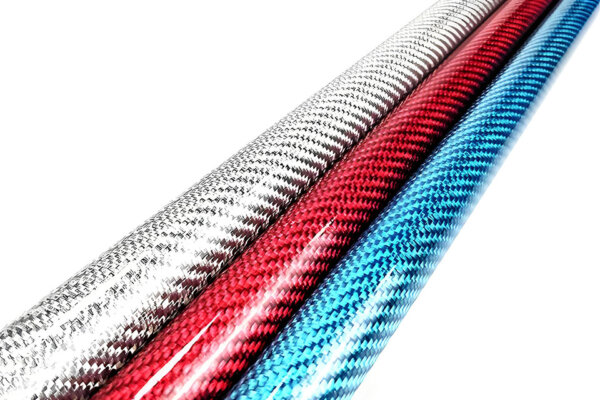

Mēs piedāvājam daudz pabeigt iespējas mūsu oglekļa šķiedras caurules. Lielākajai daļai cilvēku patīk klasiskais sarža pinums izskatu. Tas ir krusteniskais modelis, kas parāda reālo oglekļa šķiedra. Mēs to varam matēts vai glancēts. Mēs izgatavojam arī caurules ar vienvirziena vai pīnes modeļi. Dažiem lietojumiem mēs varam krāsot caurules jebkurā vēlamajā krāsā.

Mūsu oglekļa caurules ir daudz izmērss. Mēs varam veikt jebkuru diametrs no 3 mm līdz 500 mm. . sienas biezums var būt tik plānas (0,5 mm) vai tik biezas, cik nepieciešams. Mēs izgatavojam caurules standarta modulis un augsta moduļa oglekļa šķiedra. Mēs saglabājam dažus krājums izmēriem, kas ir gatavi nosūtīšanai, bet lielākā daļa mūsu cauruļu ir pasūtījuma katram pasūtījumam. Mēs varam izgatavot caurules lielie garumi līdz 3 metriem. Ja jums ir nepieciešams pielāgots griezums, mēs arī to varam izdarīt!

Izmēru opciju diagramma:

- Apaļas caurules: 3 mm līdz 500 mm OD (ārpus diametrs)

- Square carbon fiber tubes: 5mm to 300mm sides

- Sienas biezums: 0,5 mm līdz 20 mm

- Garums: Līdz 3 metriem (pēc īpašiem pasūtījumiem pieejams ilgāks)

- ID (iekšpusē diametrs): Pielāgots jūsu vajadzībām

Rūpniecības lietojumprogrammas - risinājumi katrai nozarei

Mūsu oglekļa šķiedras kārta caurules un citas formas tiek izmantotas daudzās jomās. Apbrīnojamais spēka un svara attiecība veido oglekļa šķiedras stieņi lieliski piemērots visiem šiem lietojumiem: Automašīnas un motocikli

- Rāmja daļas

- Rullīšu būri

- Piedziņas vārpstas

- Rokturu stieņi

- Ķermeņa balsti Aviācija

- Dronu rāmji

- Spārns spars

- Iekšējie balsti

- Antenu masti

- Lietderīgās slodzes struktūras Sporta aprīkojums

- Velosipēdu rāmji

- Makšķeres

- Golfa vārpstas

- Hokeja nūjas

- Telts stabi Medicīniskais aprīkojums

- Rentgena galda daļas

- Mobilo iekārtu rāmji

- Protēžu sastāvdaļas

- Ķirurģiskie instrumenti

- Attēlveidošanas iekārtas atbalsta Celtniecība un jūras kuģniecība

- Margu balsti

- Vieglas struktūras

- Laiva daļas

- Dekoratīvie elementi

- Atbalsts sijas Mūsu kvalitatīva oglekļa šķiedra caurulēm ir īpašas īpašums priekšrocības, kas palīdz katrā jomā. Tie nerūsē, ir ļoti viegli un ilgi kalpo. Portāls tiek izgatavotas oglekļa šķiedras caurules rūpējoties par visaugstāko mehāniskās īpašības.

Ieguvumu salīdzinājums:

| Īpašums | Alumīnijs | Tērauds | Oglekļa šķiedra |

|---|

| Svars | Gaisma | Smags | Ļoti viegls |

| Spēks | Labi | Ļoti labi | Lieliski |

| Korozija Izturība | Labi | Nabaga | Lieliski |

| Noguruma dzīve | Labi | Labi | Lieliski |

| Paskaties | Vienkāršs | Vienkāršs | Premium |

“The precizitāte of their tubes is amazing. Every batch is exactly the same, which helps our automated assembly process work perfectly.” – Aerospace Component Manufacturer

Mūsu vieglie kompozīti ir izgatavoti, lai precīzi atbilstu jūsu specifikācija. Kad jūs veikals oglekļa šķiedras caurules no mums iegūsiet detaļas, kas lieliski atbilst jūsu vajadzībām.

The tiek ražotas caurules mūsu tīrā, modernā rūpnīcā. Mēs pārbaudām katru cauruli, lai pārliecinātos, ka tā atbilst jūsu vajadzībām. Mēs varam pielāgot šķiedru orientēšanās padarīt cauruli stiprāku vajadzīgajā veidā.

Mūsu piedāvātie pielāgotie risinājumi:

- Īpašas formas, kas nav standarta apaļas un kvadrātveida

- Pielāgotas šķiedru kārtas īpašām stiprības vajadzībām

- Ārējais apstrāde līmēšanai vai krāsošanai

- Gala veidgabali un īpaši griezumi

- Pilnīga montāža kopā ar citiem komponentiem

Kad jums ir nepieciešams labākais salikts daļas, mūsu plašs oglekļa šķiedras klāsts produkti atbildīs jūsu vajadzībām. Mēs izgatavojam tiek izgatavotas oglekļa šķiedras caurules lai kalpotu un darbotos vissmagākajos apstākļos.

Mūsu uzņēmums var jums palīdzēt no dizaina līdz gala produktam. Mums ir ekspertu komanda, kas zina, kā izmantot oglekļa šķiedra vislabākajā veidā. Mēs sadarbojamies ar lieliem uzņēmumiem visās jomās, kuriem nepieciešamas labākās detaļas. Kāpēc mūsu caurules ir labākas:

- Izgatavots no augstākās kvalitātes CF materiāliem

- Pārbaudīts katrā posmā

- Ražots tīrā, kontrolētā rūpnīcā

- Pieejams ruļļos ietīta sarullētā sarža un citas apdares

- Izgatavots atbilstoši jūsu vajadzībām

Mums ir a oglekļa šķiedras cauruļu klāsts gatavs nākamajam projektam. Jūs varat veikals tiešsaistē vai sazinieties ar mums pielāgota oglekļa šķiedra caurules.

Vai jums ir nepieciešams ruļļos iesaiņots ogleklis caurules sporta automašīnai vai pulverizēts ogleklis caurules rūpnieciskai izmantošanai, mēs esam jūsu labākais partneris. Mūsu izturīgs caurules padarīs jūsu produktus labākus.

Pasūtīšanas process:

- Pastāstiet, kas jums nepieciešams (forma, izmērs, stiprums)

- Mūsu inženieri iesaka labāko risinājumu

- Mēs izgatavojam paraugu jūsu apstiprināšanai

- Mēs sākam ražošanu pēc tam, kad esat apstiprinājis

- Mēs sūtām savlaicīgi, katru reizi

- Jūsu produkti kļūst labāki ar mūsu detaļām Sazinieties ar mums šodien, lai uzzinātu, kādi ir mūsu oglekļa šķiedras caurules var palīdzēt jūsu produktiem!

Ieguvumi Kopsavilkums: Mūsu pielāgota oglekļa šķiedra caurules nodrošina neticamu izturību bez svara. Tās ir izgatavotas precīzi pēc jūsu specifikācijām, izskatās lieliski un kalpo ilgāk nekā metāla caurules. Ideāli piemērotas, lai padarītu jūsu produktus vieglākus, izturīgākus un iespaidīgākus jūsu klientiem.

-