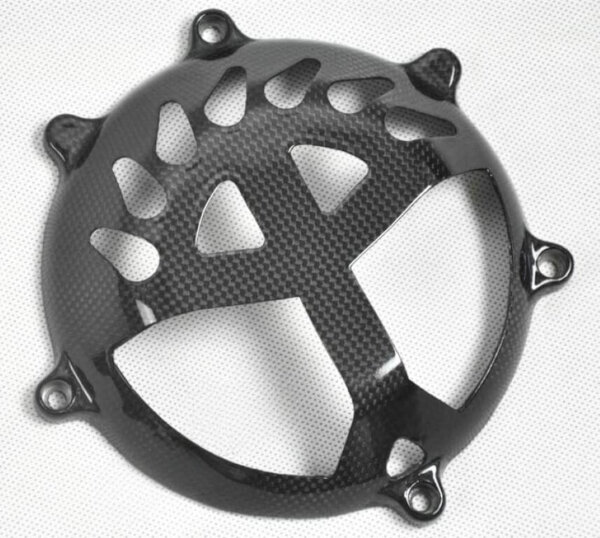

Oglekļa šķiedras kompozītmateriālu karstās presēšanas formēšanas process

Mūsu rūpnīcā tiek izmantots uzlabots oglekļa šķiedras karstās preses process ar P20 tērauda veidni, nodrošinot augstu efektivitāti, precizitāti, izturību un rentabilitāti kvalitatīvai ražošanai.