The Weight Problem That’s Costing You Money

Are you still using aluminum parts in your products? This might be a big problem.

Many companies face the same issue today. Heavy parts make products that:

- Weigh too much

- Cost more to ship

- Use more fuel

- Break down faster

- Don’t sell as well

When you make cars, bikes, planes or sports gear, every gram counts. Customers want things that are light and strong. They will pay more for better products.

Aluminum seemed good before. But now there’s something much better.

Why This Problem Is Worse Than You Think

Let’s look at what makes this weight problem so bad:

- Your competitors are already using lighter materials

- Fuel costs keep going up

- Customers demand better performance

- Safety standards get stricter each year

- Manufacturing costs eat into your profits

Look at these facts that show how bad the problem is:

Material Weight Comparison

| Material | Density | Weight Difference | What This Means For You |

|---|

| Aluminum | 2.7 g/cm³ | Baseline | Your products are too heavy |

| Carbon Fiber | 1.55-1.6 g/cm³ | 40-70% lighter | Your products could be much lighter |

When your products are too heavy, you lose money and customers.

Cars with heavy parts use more gas. Bikes with heavy frames are harder to ride. Planes with heavy bodies use more fuel. Sports gear that’s heavy doesn’t perform as well.

Every extra pound costs you in some way.

The Strength Problem

It gets worse. Aluminum isn’t just heavy – it’s also not as strong as it could be:

| Material | Tensile Strength | What This Means |

|---|

| Aluminum | 90-700 MPa | Parts can break under stress |

| Carbon Fiber | Up to 6,000 MPa | 10x stronger and more reliable |

Your aluminum products might be failing too soon. This leads to:

- Unhappy customers

- More warranty claims

- Bad reviews

- Lost sales

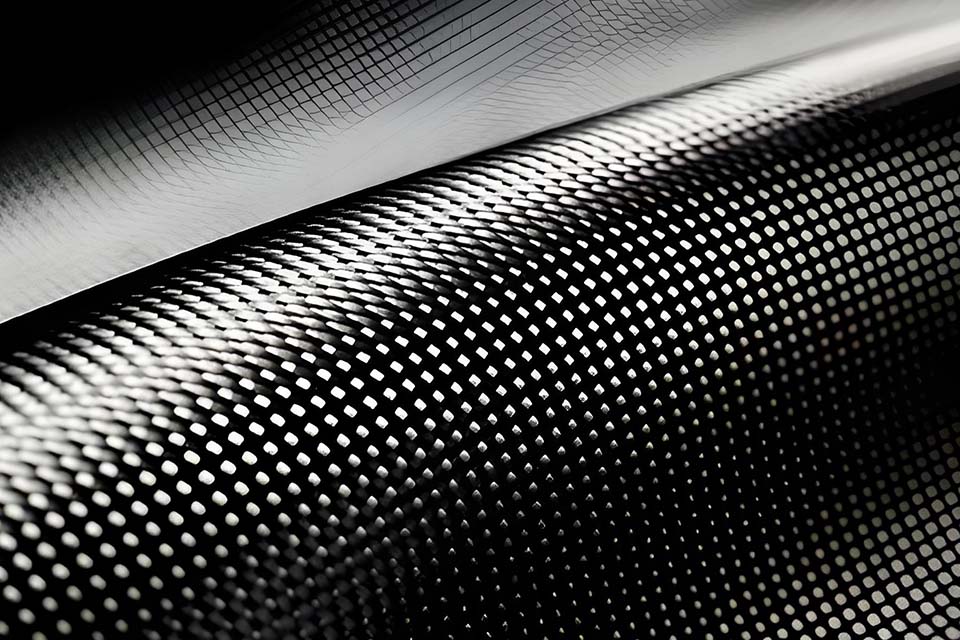

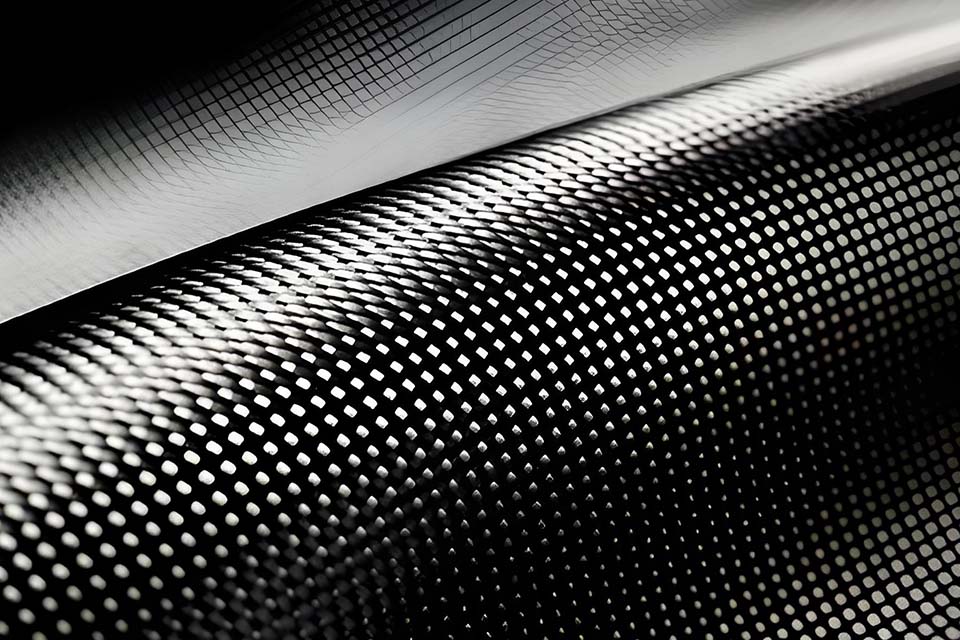

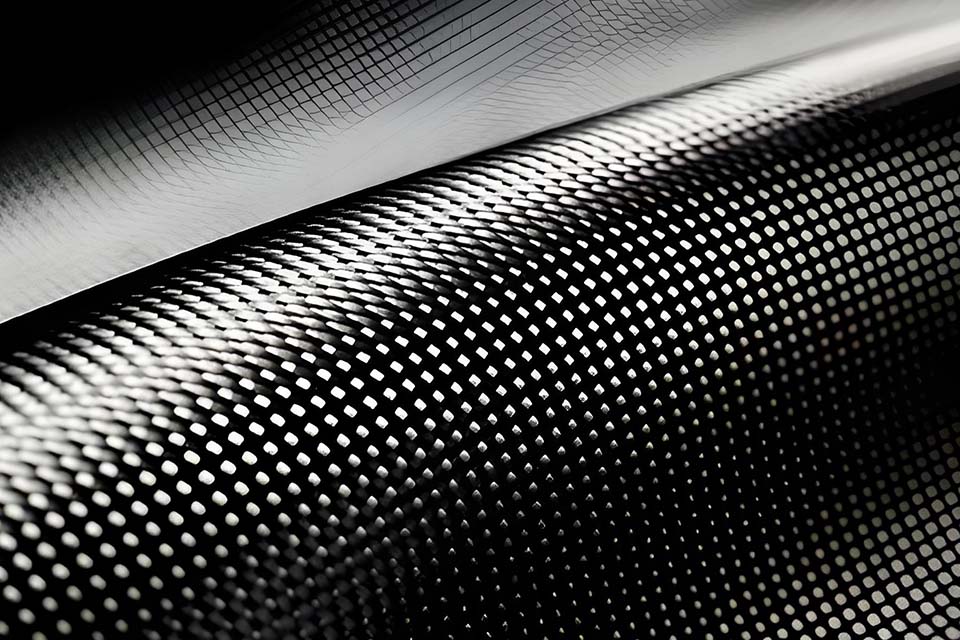

The Simple Solution: Carbon Fiber

The answer to these problems is carbon fiber. Our company has made custom carbon fiber products for 28+ years in China.

Carbon fiber fixes all the problems that aluminum causes:

- It’s 40-70% lighter than aluminum

- It’s 10 times stronger than most aluminum alloys

- It lasts longer in tough conditions

- It gives products a high-end look customers love

- It helps you stand out from competitors

Real companies see real results with carbon fiber:

- Aircraft makers save 12% on fuel costs when they use carbon fiber doors

- Car makers like BMW use carbon fiber to make cars 30% lighter

- Racing teams gain big advantages with 40% weight reduction

Why Our Carbon Fiber Products Work Better

As an OEM/ODM carbon fiber manufacturer with 28+ years of experience, we know how to make the perfect parts for your needs.

Our Manufacturing Strengths:

- Full Custom Service – We make exactly what you need

- 28+ Years Experience – We know all the best methods

- Quality Control – Every part is perfect

- Fast Production – Get your parts when you need them

- Competitive Pricing – Great value for high-end materials

How We Make Carbon Fiber Work For You

We help you at every step:

- Design Help – We improve your designs for carbon fiber

- Material Selection – We pick the right type for your needs

- Testing – We make sure it works perfectly

- Production – We make it fast and right

- Delivery – We get it to you on time

Carbon Fiber in Different Industries

Our carbon fiber products work in many industries:

For Car Makers

We make carbon fiber car parts that help:

- Cut weight by up to 70%

- Improve speed and handling

- Use less fuel

- Look more high-end

- Pass safety tests easily

For Motorcycle Companies

Our carbon fiber motorcycle parts deliver:

- Much lighter bikes

- Better racing performance

- Stronger frames

- Custom looks

- Better fuel use

For Sports Equipment

We make carbon fiber parts for:

- Tennis rackets

- Golf clubs

- Bicycle frames

- Helmets

- Sporting goods

For Aerospace

Our carbon fiber helps make:

- Lighter plane parts

- Helicopter blades

- Satellite components

- Drone frames

- UAV bodies

Real Results From Real Customers

Here’s what happens when companies switch from aluminum to our carbon fiber:

| Product | Weight Reduction | Strength Increase | Customer Benefit |

|---|

| Car Body Panels | 50% lighter | 400% stronger | Faster cars that use less gas |

| Bike Frames | 60% lighter | 300% stronger | Bikes that are easier to ride |

| Drone Bodies | 70% lighter | 500% stronger | Drones that fly longer |

| Sports Equipment | 40% lighter | 200% stronger | Better performance for athletes |

How We Work With You

Our custom carbon fiber process is simple:

- You tell us what you need

- We help improve the design

- We make samples for you

- You approve the samples

- We make your full order

- We ship it to you fast

Why Choose Us Over Other Manufacturers

Many carbon fiber makers exist, but we offer:

- 28+ Years Experience – We know what works

- Full Custom Service – Not just standard parts

- Better Pricing – Direct from our factory

- Higher Quality – We test everything

- Faster Delivery – We don’t waste time

The Cost Benefit of Carbon Fiber

Yes, carbon fiber costs more than aluminum at first. But look at the full picture:

| Factor | Aluminum | Carbon Fiber | Long-Term Benefit |

|---|

| Initial Cost | $3-6/kg | Higher | One-time expense |

| Weight | Heavier | 40-70% lighter | Save money on fuel forever |

| Strength | Good | Excellent | Fewer replacements needed |

| Lifespan | Good | Excellent | Less maintenance |

| Customer Appeal | Standard | Premium | Charge more for your products |

While aluminum may seem cheaper now, carbon fiber saves money over time.

How to Get Started

Ready to solve your weight problems with carbon fiber? Here’s how:

- Contact us – Tell us what you need

- Get a quote – We’ll give you pricing fast

- Review samples – See our quality firsthand

- Place your order – We’ll start right away

- Receive your parts – Start making better products

What Our Customers Say

“We cut our bike weight by 40% when we switched to Haoyue carbon fiber parts. Our sales went up 35% the next year.” – Sports Company CEO

“The carbon fiber drone bodies let us fly 15 minutes longer on the same battery. That’s a game changer.” – Drone Manufacturer

“Our carbon fiber car parts not only made the cars faster, they also looked so good that we could charge more for them.” – Auto Parts Supplier

Common Questions About Carbon Fiber

Q: Is carbon fiber really worth the extra cost? A: Yes! The weight savings, strength, and customer appeal more than pay for the difference.

Q: Can you match the exact shape of our aluminum parts? A: Yes, we can make carbon fiber in any shape you need.

Q: How long does it take to get carbon fiber parts made? A: We can deliver samples in 2 weeks and full orders in 4-8 weeks.

Q: Is carbon fiber good for the environment? A: Carbon fiber products use less fuel and last longer, which helps the environment over time.

Ready to Solve Your Weight Problems?

Don’t let heavy aluminum parts hold your products back any longer. Our carbon fiber solutions will:

- Make your products much lighter

- Make them far stronger

- Help them last longer

- Make them look better

- Make your customers happier

With 28+ years making the best carbon fiber parts, we are ready to help you today.

Contact us now to see how we can make your products better with carbon fiber!