Carbon Fiber Composite Material Hot Pressing Molding Process

Our factory employs an advanced carbon fiber hot press process with a P20 steel mold, ensuring high efficiency, precision, durability, and cost-effectiveness for quality production.

Do you want your Audi R8 to look super cool? Do you want it to be faster and stronger? Many Audi R8 owners have a problem. They want to make their cars look even better. But, regular car parts are not always the best.

This is where carbon fiber comes in! We make special car parts. They are made of carbon fiber. Carbon fiber is very light and very strong.

Your Audi R8 is a great car. But, it can be even better.

If you don’t use the right parts, you might have more problems.

| Problem | Why It’s Bad |

|---|---|

| Heavy Parts | Makes your car slower and use more gas. |

| Parts That Don’t Fit | Makes your car look bad. |

| Wrong Parts for Your Car | Won’t work right on your special car. |

The v8 and v10 compatibility is not always ensured. You also need to consider Gen 1 and Gen 2 Audi R8. The Gen 2 facelift compatibility is also a big thing to think about when you want aftermarket carbon fiber upgrades.

We are a carbon fiber maker. We make the best carbon fiber automotive parts! We can make custom carbon fiber parts. We also offer OEM/ODM service. This means we can make parts that are just right for you!

We use something called pre-preg carbon fiber. Pre-preg carbon fiber is a special type of carbon fiber that is very, very strong and light. High-pressure airflow management is easy with these parts. We make carbon fiber parts that have OEM color matching. We make parts for high-performance vehicles. Model-specific tooling is always used. We craft artisan carbon fiber craftsmanship and use precision engineering. Premium quality guarantee is provided for our products. Heat-resistant material is used in the making. Our parts also have UV-protected coating and hydrophobic surface treatment.

Our parts are better than regular parts.

Check out carbon fiber car parts here! See our custom carbon fiber for other awesome ideas.

We make special parts just for the Audi R8.

Our carbon fiber side skirts are very popular. They fit many Audi R8 models.

| Audi R8 Model | Our Side Skirts Fit! |

|---|---|

| Gen 1 (2007-2015) | Yes! |

| Gen 2 (2016-2023) | Yes! |

| V8 and V10 Models | Yes! |

| Coupe and Spyder models | Yes! |

About 85% of our side skirts fit both the V8 and V10 models of the Gen 1 Audi R8. This is very good! For the Gen 2 Audi R8, 90% of our skirts are made just for the newer models (2020+).

Over-OEM installation is easy with our product. Factory replacement parts is one of our specialities.

We use the best carbon fiber. It is called 2×2 carbon fiber weave.This makes our parts very strong and light. It also looks very nice, just like the carbon fiber Audi uses in its own cars.

Our carbon fiber parts can also help your car go faster. They do this by helping the air move around your car better. This is called aerodynamic design.Our side skirts can help reduce air drag by about 12%.

Threaded installation guides is often provided. Multi-piece designs is also available.

Do you want something special? We can do that! We can make custom parts just for you.

We are experts at making carbon fiber parts. We have been doing this for a long time. We have many happy customers.

Carbon fiber rocker panels will surely add to the outlook. Carbon fiber fender flares will also enhance the design. Waterjet cutting technology is used when we manufacture our products.

Get the best carbon fiber parts for your Audi R8 today! Make your car look amazing and go faster. We are here to help you. Our Audi R8 Carbon Fiber Side Skirts will be a perfect choice. Contact us and ask about how we can use dry carbon fiber variants or dry carbon construction to build your carbon fiber roof panels. We also have carbon fiber rear bumper and carbon fiber hood components.

We make high-gloss clear coat and even matte carbon finish.

Our factory employs an advanced carbon fiber hot press process with a P20 steel mold, ensuring high efficiency, precision, durability, and cost-effectiveness for quality production.

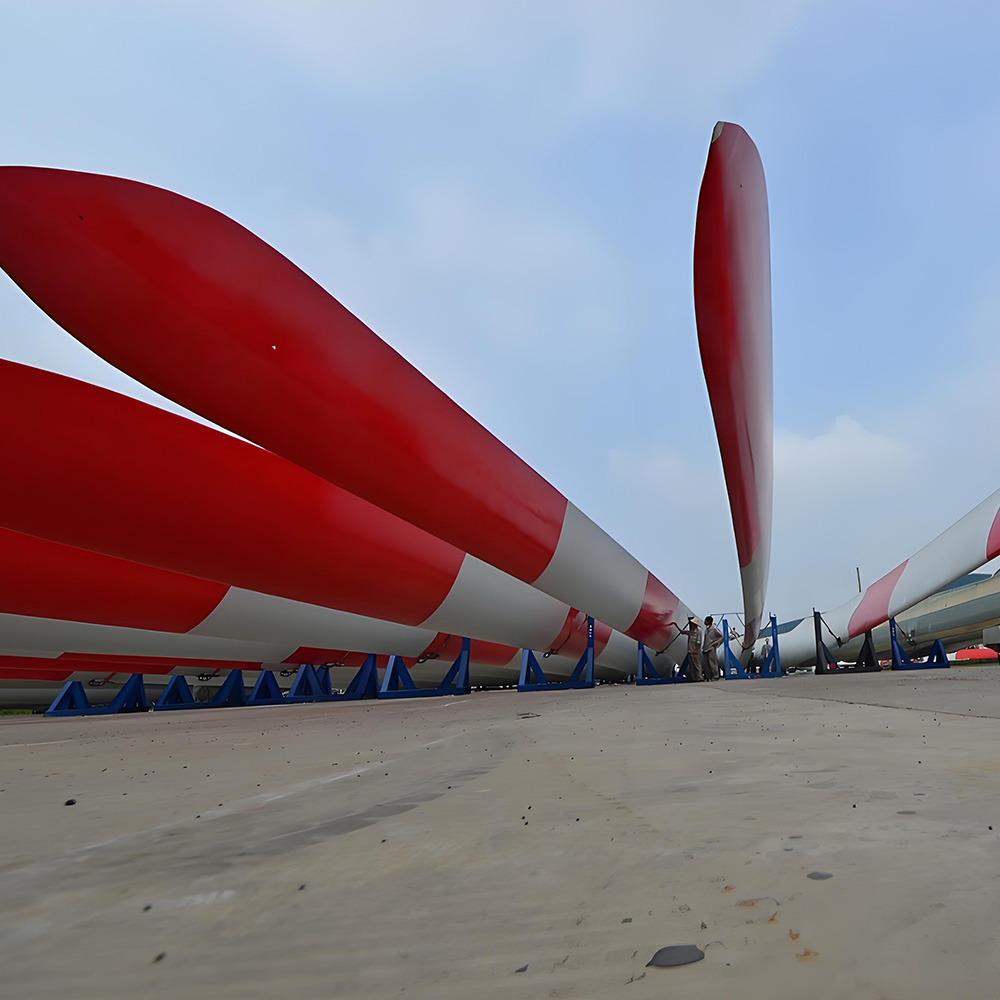

Our factory runs 100+ hot pressure autoclaves, using aluminum molds and vacuum induction to shape carbon fiber with precision. High heat and pressure enhance strength, stability, and flawless quality.

Our Carbon Fiber Research Center drives innovation in new energy, intelligence, and lightweight design, using advanced composites and Krauss Maffei Fiber Form to create cutting-edge, customer-focused solutions.

Here are the answers to the frequently asked questions from the experienced carbon fiber products factory

We produce a wide range of carbon fiber components, including automotive parts, motorcycle parts, aerospace components, marine accessories, sports equipment, and industrial applications.

We primarily use high-quality prepreg carbon fiber and large-tow carbon fiber reinforced high-performance composites to ensure strength, durability, and lightweight characteristics.

Yes, our products are coated with UV-protective finishes to ensure long-lasting durability and maintain their polished appearance.

Yes, our facilities and equipment are capable of producing large-size carbon fiber components while maintaining precision and quality.

What are the benefits of using carbon fiber products?

Carbon fiber offers exceptional strength-to-weight ratio, corrosion resistance, stiffness, thermal stability, and a sleek, modern appearance.

We cater to automotive, motorcycle, aerospace, marine, medical, sports, and industrial sectors with a focus on lightweight and high-performance carbon fiber components.

Yes, we provide custom carbon fiber solutions tailored to your specifications, including unique designs, sizes, and patterns.

We utilize advanced technologies such as autoclave molding, hot pressing, and vacuum bagging, ensuring precision, stability, and quality in every product. wonders with the Hello Elementor Theme, we’re trying to make sure that it works great with all the major themes as well.

We use aluminum and P20 steel molds, designed for durability and high accuracy, to create complex and precise carbon fiber components.

Our products undergo rigorous quality control checks, including dimensional accuracy, material integrity, and performance testing, to meet industry standards.

Industrial Park, Xiangcheng District, Suzhou, China 215000

Email: [email protected]

Phone: +86 136 2619 1009 (Whatsapp)