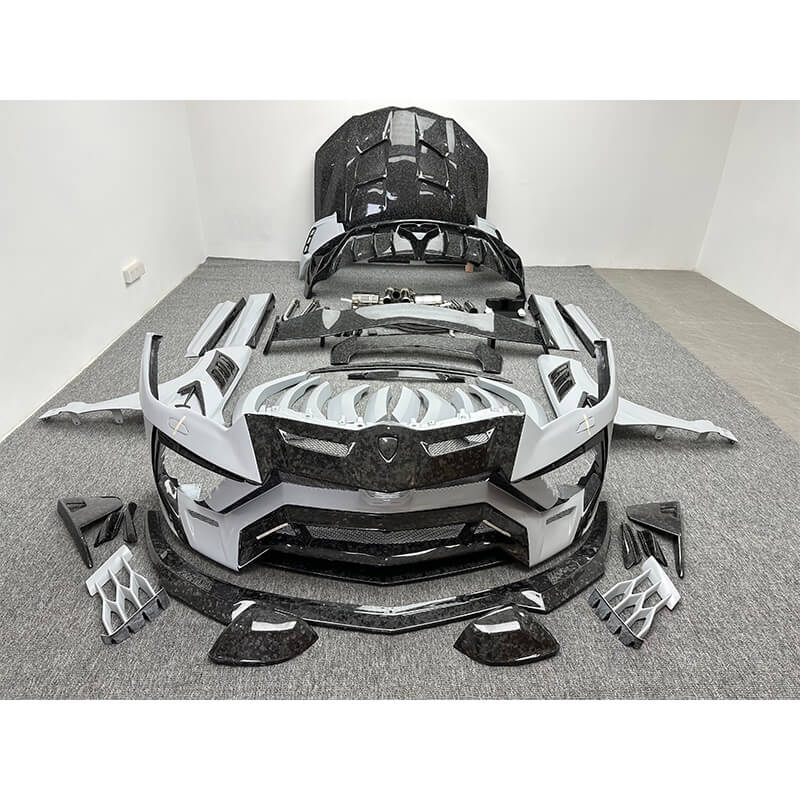

Carbon Fiber Composite Material Hot Pressing Molding Process

Our factory uses an advanced carbon fiber hot press molding process, using a P20 steel mold, consisting of an upper and lower part. The prepreg is placed between the molds and subjected to high pressure and temperature to shape and cure the part. The process provides excellent production efficiency, precise dimensional accuracy, cost-effective products and long-lasting mold durability.