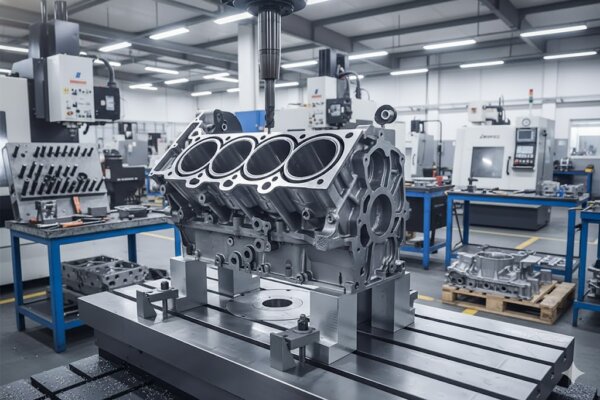

Procesi i formimit të materialit të përbërë me fibër karboni me presion të nxehtë

Fabrika jonë përdor një proces të avancuar të shtypjes së nxehtë me fibër karboni me një kallëp çeliku P20, duke siguruar efikasitet të lartë, saktësi, qëndrueshmëri dhe kosto-efektivitet për prodhim cilësor.