Welcome to the future of aircraft design. Our fibër karboni me porosi manufacturing plant brings you the best in hapësirës ajrore technology. We make strong and lightweight pjesë për modern aviation. Tona carbon fibre composites help make planes that fly better, use less fuel, and last longer.

We work with big names like DJI. Our parts are in the DJI. From small planes to big commercial aircraft, we make parts that make a big difference.

Why Choose Our Carbon Fiber Composite Solutions?

- Pesha më e lehtë: Our parts are up to 50% lighter than metal parts

- Stronger Structure: 5x stronger than steel but much lighter

- Fuel Savings: Planes use up to 20% less fuel with our parts

- Jetë më e gjatë: Our parts don’t rust and last longer

- E bërë me porosi: We make parts just for your needs

Të aviation industry is changing fast. Fibër karboni is a big part of this change. Our plant makes material kompozit that helps make planes better in many ways.

Carbon fiber reinforced parts are changing how planes are made. The aerospace industry likes our parts because they are light but very strong. This helps planes fly farther using less fuel.

Ne përdorim më të mirën rrëshirë dhe fiber reinforced polymer systems. This makes our composite structure parts very strong. We can make any part of a plane, from the wings and fuselage to small composite parts inside.

Aircraft manufacturers like working with us because our parts help them meet their goals. Their planes can fly farther, carry more, and cost less to run with our parts.

“Your carbon fiber components have helped us reduce our fleet’s weight by 15%, resulting in significant fuel savings and extending our aircraft’s service life.” – Major Airline Technical Director

Unmatched Fuel Efficiency with Lightweight Carbon Fiber Solutions

Fuel efficiency is very important in the airline industry. Tona carbon fibre composites help planes use less fuel. This saves money and helps the earth too.

When a plane is made with our carbon fiber aircraft parts, it is much lighter. A lighter plane needs less fuel to fly the same distance. This means big savings for airlines.

Të Boeing 787 uses our parts and can fly very far using less fuel. The ulje në peshë from using our parts means the plane can carry more people or cargo.

Aircraft designers love working with our karbonit fiber in aircraft parts. They can make new shapes that help planes fly better. This makes the plane use even less fuel.

Comparison of Materials Used in Aircraft Construction

| Materiali | Pesha | Forca | Corrosion Resistance | Fatigue Resistance | Kostoja |

|---|

| Fibër karboni | Shumë e lehtë | Shumë e lartë | E shkëlqyeshme | E shkëlqyeshme | Higher Initial |

| Alumini | Drita | E mesme | Good with Treatment | Mirë | E mesme |

| Çeliku | E rëndë | Lartë | Poor to Medium | E mesme | E ulët |

| Titanium | E mesme | Shumë e lartë | E shkëlqyeshme | E shkëlqyeshme | Shumë e lartë |

Aerodynamic performance is key to good aircraft design. Tona kompozit me fibër karboni parts help make planes that cut through the air better. This means less drag and better flying.

Të composite panel parts we make can be shaped in ways metal can’t. This lets designers make new shapes that work better. The airframe can be smoother and more streamlined.

Tona carbon fiber reinforced plastic (CFRP) parts are also very strong against hits. They have good impact resistance and don’t dent like metal. This means less damage and less fixing needed.

Të ngurtësi of our parts helps keep the plane’s shape even when flying fast. This makes the plane safer and more comfortable to fly in.

Key Benefits of Carbon Fiber in Different Aircraft Applications

- Krahët: Better shape, less bend, lighter weight

- Fuselage: Stronger, lighter, better pressure handling

- I brendshëm: Fire resistant, lighter, looks better

- Pjesët e motorit: Heat resistant, lighter, longer lasting

- Control Surfaces: More responsive, lighter, stronger

Technical Specifications of Our Carbon Fiber Aircraft Components

Tona pjesë të fibrave të karbonit meet all the strict rules for aviation. We test every part to make sure it’s perfect before it leaves our plant.

CFRP parts we make have these features:

- Tensile Strength: 3,500-7,000 MPa

- Density: 1.55-1.75 g/cm³

- Temperature Resistance: Up to 177°C (350°F)

- Fatigue Life: 3-5 times longer than aluminum

- Chemical Resistance: Excellent to most fluids used in aircraft

We use different types of fibra karboni për punë të ndryshme:

- High Modulus for very stiff parts

- High Strength for parts that need to be very strong

- Standard Modulus for most aircraft parts

- Intermediate Modulus for a good mix of stiffness and strength

Tona teknikat e prodhimit are the best in the world. We use:

- Vendosja e automatizuar e fibrave

- Resin Transfer Molding

- Vacuum Assisted Resin Transfer Molding

- Kurim me autoklavë

- Out-of-Autoclave Processing

“The precision and quality of your carbon fiber components exceed industry standards. They’ve become an integral part of our aircraft design strategy.” – Chief Engineer, Leading Aircraft Manufacturer

Historitë e suksesit të klientit

Tona fibër karboni parts have helped many companies make better planes. Here are some success stories:

Regional Jet Manufacturer

They used our composite aircraft parts to make a new small jet. The plane is 25% lighter than older models. It can fly 30% farther on the same amount of fuel. Airlines love it because it costs less to run.

Military Aircraft Upgrade

A military aircraft maker used our parts to make their planes better. The planes can now carry more weapons and fly farther. The parts also made the planes harder to see on radar.

Private Aircraft Builder

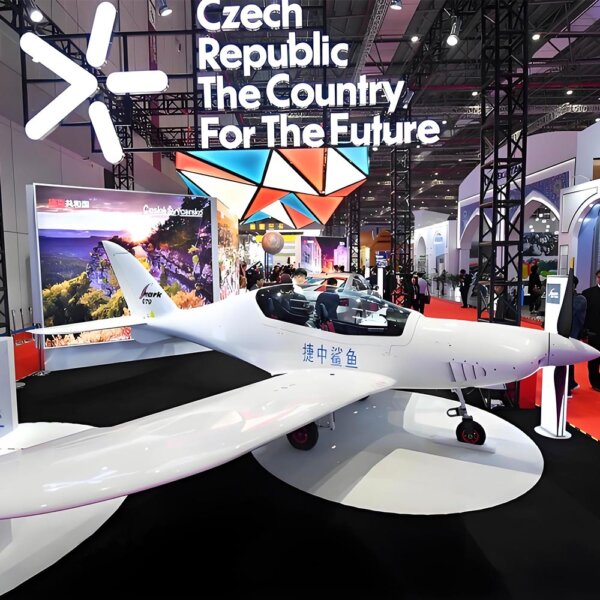

A company that makes small planes for private owners used our parts. Their new plane is faster and can fly farther than any other plane its size. It looks better too, with smooth shapes that weren’t possible before.

Si punojmë me ju

Working with us is easy. We help you all the way from idea to finished part.

- Consultation: We talk about what you need and how we can help

- Dizajn: Our engineers work with yours to design the perfect part

- Prototipizim: We make test parts to make sure the design works

- Testimi: We test the parts to make sure they meet all rules

- Prodhimi: We make the parts in the amounts you need

- Mbështetje: We help you use the parts and make them better

Our plant can make parts for:

- Commercial airplanes

- Military and civilian aircraft

- Small private planes

- Helicopters

- Space vehicles

- Dronët

Why Our Carbon Fiber is Better for Aircraft

Materials like carbon fiber are not all the same. Ours is made just for aircraft use. We use special epoksi that works well in the air where it’s cold and the air is thin. Our fiber materials are tested more than others. We know they will work every time. This means your planes will be safer and more reliable.

Të strength properties 94. i përshtatet në mënyrë të përsosur me makinën tuaj fibër karboni are the best in the world. Our parts can hold more weight while being lighter themselves. Carbon fiber also lasts longer than metal. It doesn’t get tired as fast. This means parts don’t need to be fixed or changed as often.

Environmental Benefits of Carbon Fiber in Aviation

Using our fibër karboni parts helps the earth too:

- Less fuel used means less pollution

- Planes last longer, so fewer new ones need to be made

- Our making process uses less energy and makes less waste

- Parts can be recycled at the end of their life

Are you ready to make your planes better with fibër karboni? Our team is here to help. We can make any part you need, from small clips to big composite fuselage sections. The use of composites in planes is growing fast. Don’t get left behind. Talk to us today about how we can help you make better planes. Our fibër karboni me porosi plant has helped many companies in the aircraft industry. We can help you too. Just reach out to us to start the conversation.

Carbon fiber has been used to make planes better for years. But our new methods and materials make it even better. Let us show you what we can do.

Additional Resources

Want to learn more about carbon fiber in aircraft? Check out these pages:

Summary: Transform your aircraft with our premium carbon fiber composites for 50% weight reduction, 5x strength of steel, and 20% fuel savings. Our aerospace-grade materials are used by Boeing and Airbus for superior performance, longer service life, and reduced maintenance costs.