Real vs Fake Carbon Fiber: How to Tell the Difference

Walk around any tuning show or exotic-car meet, and you’ll see it everywhere — that hypnotic black-and-gray weave glinting under spotlights. But here’s the catch: much of what passes for “carbon fiber” today isn’t carbon at all.

The global composites boom has made the look easy to copy but the performance nearly impossible to fake. From hydro-dipped plastics to vinyl wraps and fiberglass dressed in imitation weave, counterfeit materials now outnumber the genuine article ten to one.

The question isn’t just aesthetic. It’s technical, emotional, and financial: are you getting the strength, lightness, and integrity you paid for — or a plastic illusion?

1. Why It Matters

Carbon fiber isn’t just a fashion statement; it’s a structural revolution. In the aerospace and motorsport worlds, every gram shaved from a part translates to speed, efficiency, and endurance. A single carbon-fiber hood can drop 8 kg from the nose of a car — a difference that changes balance, braking, and cornering feel.

Fake parts mimic the appearance but not the physics. Most are resin-rich fiberglass shells or ABS plastic coated in printed weave. They may look right on day one, but under real-world stress they tell a different story:

- Heat from an engine bay warps the resin.

- UV exposure yellows the clear coat.

- Structural weakness turns a cosmetic mod into a safety risk.

This isn’t paranoia. In 2024, a European tuning shop documented three separate diffuser failures traced to fake “dry-carbon” panels. The cars lost aerodynamic stability at highway speed — a costly lesson in why authenticity matters.

2. What Real Carbon Fiber Is Made Of

True carbon fiber starts life not as fabric, but as chemistry. A polymer called polyacrylonitrile (PAN) is spun into filaments thinner than a human hair, then carbonized in a 1,000 °C furnace until only carbon atoms remain. Those filaments are woven into oglekļa šķiedras audums, which becomes the skeleton of the composite.

2.1 From Filament to Fabric

Each bundle — called a tow — contains 3,000 to 12,000 filaments aligned in perfect tension. The tighter and more consistent the weave, the stronger and lighter the finished part.

2.2 Prepreg, Resin, and the Art of Balance

Real manufacturers use pre-impregnated (prepreg) carbon sheets where every fiber strand is uniformly coated with aerospace-grade epoxy resin. This precision matters: too much resin adds weight; too little causes voids and delamination.

2.3 The Cure That Defines Quality

Once layered, the sheets are vacuum-bagged and autoclave-cured — a process using both pressure and heat to compress every micro-air pocket out of the laminate. That’s why a genuine Lamborghini Huracán spoiler or a Ķīnas oglekļa šķiedras diffuser feels like sculpted marble — perfectly smooth, feather-light, and impossibly stiff.

Fake versions simply cannot replicate that molecular density. Their resin cures at ambient pressure, trapping micro-bubbles that weaken the structure.

3. The Most Common Fake “Carbon Fiber” Methods

Every counterfeiter exploits one truth: most people buy with their eyes. Here are the tricks behind the fakes:

| Fake Type | Apraksts | Hidden Problem |

|---|---|---|

| Vinyl Wraps | Printed weave film on metal or ABS | No structural benefit; bubbles and peeling inevitable |

| Hydro-Dipped Plastic | Pattern floated on water, transferred like paint | Zero carbon content; fades fast under UV |

| Fiberglass with Printed Layer | Fiberglass sheet coated with printed pattern | Heavier, weaker, often yellows |

| Carbon-Coated ABS | Paper-thin carbon veneer glued on plastic | Backside reveals molded ABS |

| Colored “Carbon” | Blue/red/gold threads for “style” | Usually dyed fiberglass; more fashion than function |

These products sell on looks. But when used in load-bearing parts — a hood, splitter, or rear wing — they can turn dangerous.

4. 7 Proven Ways to Identify Real vs Fake Carbon Fiber

📹 Pro Tip: For the best results, combine these tests. A short video or high-resolution images comparing real vs. fake parts would make these differences instantly clear.

🔊 (1) The Knock or Tap Test

Engineers love this one because your ears rarely lie. Tap the surface with your knuckle or a coin:

- Īsta oglekļa šķiedra resonates — a crisp, hollow “ping.”

- Fake parts sound dull and muted, like tapping on solid plastic.

That sound difference comes from stiffness and internal damping. Carbon-fiber composites transmit vibration sharply; plastics absorb it.

👆 (2) The 3D Feel Test

Run your fingertips across the weave. Real carbon fiber has micro-contours; you can feel the fabric threads under the clear coat. Hydro-dipped parts feel like smooth plastic film because that’s exactly what they are.

✨ (3) Pattern Consistency & Depth

Hold it under sunlight or a bright light. Real weave shows depth — like a hologram that shifts as you move. Printed patterns stay flat, with no parallax effect. Also check alignment at corners or joins: high-end makers like Ķīnas oglekļa šķiedras mirror the weave symmetrically — a detail fakes ignore.

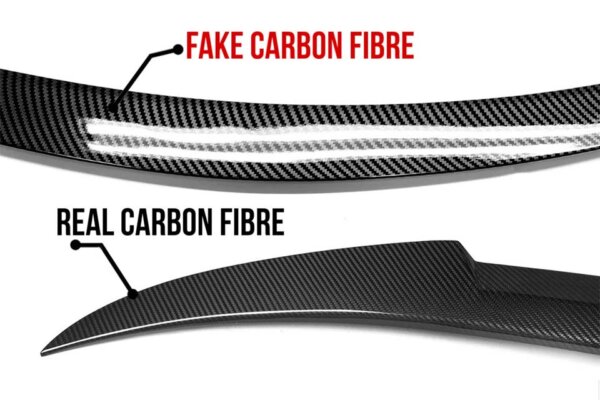

⬇️ (4) Look Beneath the Skin

Flip the piece. Real carbon is carbon through-and-through, not just a surface layer. If you see white fiberglass, injection-molded ribs, vai primer gray, you’re looking at imitation. This is one of the most reliable quick checks for any buyer.

⚖️ (5) The Weight and Balance Test

A genuine autoclave-cured panel can cut 50% of the mass of its fiberglass twin. Take a oglekļa šķiedras kapuci for instance: a real one weighs ~6 kg; a fake, up to 12 kg. That difference isn’t subtle — it changes how the car drives and how the suspension loads.

💪 (6) The Flex and Stiffness Test

Press lightly at the edge. Carbon fiber doesn’t “give.” Its modulus rivals steel. If it flexes like plastic, it ir plastic. Engineers call this the modulus of elasticity — one reason real CFRP parts feel cold and confident when you handle them.

🔬 (7) Advanced Verification

If you’re serious, go scientific:

- Conductivity test: carbon conducts electricity; fiberglass doesn’t. (Use a multimeter).

- Microscope check: under 10× magnification, real fibers look continuous and black, not pixel-printed.

- Ultrasound or eddy-current scan: non-destructive methods used by the aerospace industry to confirm layer bonding.

5. Real vs Fake Carbon Fiber — Technical Comparison

| Īpašums | Īsta oglekļa šķiedra | Fake Imitations |

|---|---|---|

| Core Material | PAN-based carbon filament + epoxy | ABS / fiberglass / hydro film |

| Manufacture | Autoclave-cured laminate | Room-temp coating or print |

| Blīvums | 1,6 g/cm³ | 2.0–2.3 g/cm³ |

| Elastic Modulus | 230 GPa | 20–40 GPa |

| Thermal Resistance | 180–200 °C | 60–90 °C |

| Electrical Conductivity | Conductive | Insulating |

| Typical Lifespan | 10 + years | 1–3 years before yellowing |

| Cenu diapazons | Higher (due to raw fibre + cure) | Lower (aesthetic only) |

Numbers don’t lie — fakes weigh more, flex more, and fail sooner.

6. Buyer’s Checklist: How to Buy Real Carbon Fiber with Confidence

- Ask about the process. True parts specify “autoclave” or “vacuum-infused,” not “carbon look.”

- Inspect the backside. Real weave continues underneath; this is a non-negotiable check.

- Demand data. Genuine suppliers list weight, weave type (2×2 twill, 1×1 plain), and resin system.

- Check brand lineage. Makers like SMI Composites, IndiCarbon, un Ķīnas oglekļa šķiedras document their production chain.

- Avoid bargains that defy physics. If a “full carbon hood” costs less than the raw material, it isn’t full carbon.

🧭 Real brands talk about fibre orientation, resin ratio, and cure pressure. Marketing brands talk only about gloss.

7. When to Seek Professional Verification

If you’ve spent thousands on body kits or motorcycle parts, confirmation is cheap insurance.

- Microscopic fibre analysis reveals if it’s carbon or glass.

- Ultrasonic lamination check detects air voids and delamination.

- Resistivity test verifies the electrical signature of true carbon.

Labs across Europe and Asia now offer composite authenticity certificates — an emerging standard for high-value aftermarket components.

8. Where to Buy Authentic Carbon Fiber Parts

Buy from builders, not brokers. Look for companies with a documented manufacturing process, such as:

- Chinacarbonfibers.com — 28 years of composite R&D, serving OEMs and supercar tuners.

- Voršteiners — pioneers of structural carbon aero.

- Novitec — Ferrari and Lamborghini specialists.

- 1016 Nozares — American innovator using aerospace prepreg.

Explore authentic carbon fiber car kits vai motorcycle carbon components. They cost more, but you’re buying engineering, not illusion.

9. Related FAQs

Is hydro-dipped carbon fiber real? No. It’s ink on plastic — beautiful, but not structural.

Why does real carbon fiber yellow? Epoxy resin oxidizes under UV. Professional shops re-clear using UV-stable coatings every few years.

Can fake parts harm my car? Yes. Poor adhesion can cause detachment at high speed — especially spoilers or diffusers.

Why is real carbon fiber so expensive? Because you’re paying for temperature-controlled curing, precision lay-up, and aerospace-grade fibre — not a sticker. The raw materials and process, as defined by organizations like the American Composites Manufacturers Association, are inherently costly.

How do I maintain genuine carbon fiber? Keep it waxed, out of prolonged UV exposure, and avoid harsh or abrasive chemical solvents to preserve the clear coat.

10. Final Thoughts — Authenticity You Can Feel

Real carbon fiber has a soul. Pick it up, and you’ll feel the density of thousands of aligned filaments — a material born from fire, pressure, and intention. Fake versions only imitate the surface; they can’t replicate the discipline behind the weave.

In the end, this isn’t about vanity. It’s about respect — for craftsmanship, for science, and for the machines that carry us faster than ever.

When in doubt, trust your senses… and trusted makers like Ķīnas oglekļa šķiedras. Because real carbon fiber doesn’t just look different — it behaves dažādi.