Pjesë me fibër karboni Ferrari 458 Italia: Bëni makinën tuaj më të mirë

A keni një Ferrari 458 Italia? Është i shpejtë. Është e kuqe. Por kështu janë edhe shumë makina të tjera.

Ferrari juaj duhet bie në sy. Makinat e thjeshta duken njësoj. Ata nuk tregojnë se kush jeni. Shoferët e tjerë kanë të njëjtën makinë si ju.

Një Ferrari i thjeshtë ka probleme:

- është shumë e rëndë

- Duket si të gjithë Ferrari-t e tjerë

- Nuk tregon stilin tuaj

Dhimbja përkeqësohet: Çfarë ndodh kur nuk përmirësoni

Kur vozitni Ferrarin tuaj të aksioneve, ndodhin gjëra të këqija:

- Njerëzit shohin vetëm një makinë tjetër të kuqe

- Makina juaj nuk është aq e shpejtë sa mund të ishte

- Ju mungon wow faktor

- Përzihesh me makina të tjera

Në ekspozitat e makinave, askush nuk bën foto të makinës suaj. Në rrugë, Ferrari të tjerë duken njësoj si tuajat. E juaja Makinë $200000 duket si makina e të gjithëve.

Zgjidhja: Pjesët e personalizuara me fibër karboni e bëjnë Ferrarin tuaj të veçantë

Ne bëjmë pjesë të fibrave të karbonit që zgjidh të gjitha këto probleme! Fabrika jonë përdor fibër karboni prepreg endje e thjeshtë me teknologjia e formimit me autoklavë. Kjo bën pjesë që janë:

- Më të lehta sesa pjesët e aksioneve

- Më të fortë sesa pjesët e aksioneve

- Duket më mirë sesa pjesët e aksioneve

Tona fibër karboni me porosi pjesët i japin Ferrarit tuaj pamjen dhe ndjesinë e një makine garash!

Çfarë mund të bëjnë pjesët me fibër karboni për Ferrari 458 tuaj

Bëni makinën tuaj më të shpejtë

Fibra e karbonit është e lehtë. Makinat e lehta ecin më shpejt. Është kaq e thjeshtë.

Pjesët tona mund ta bëjnë makinën tuaj deri në 50 kilogramë më e lehtë. Kjo do të thotë:

- Nisje më e shpejtë

- Më mirë kthesë

- Përdorimi më i vogël i gazit

Bëjeni makinën tuaj të duket më mirë

Pjesët tona kanë një përfundim transparent me shkëlqim ashtu si Aksesorë OEM Ferrari. Ata përshtaten perfekt në makinën tuaj.

Shikoni çfarë tha një klient:

"Ferrari im mori $16,000 më shumë në ankand me pjesë të shtuara të fibrave të karbonit."

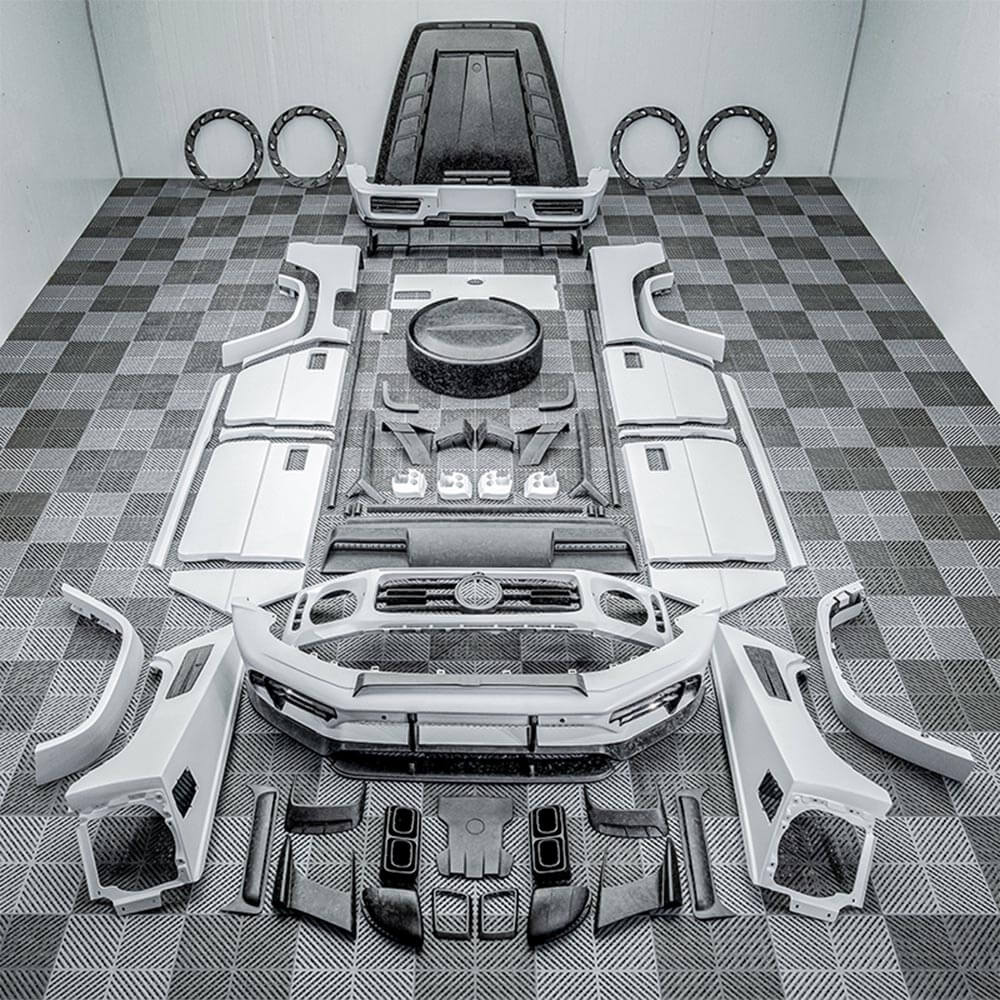

Pjesët tona më të mira me fibër karboni për Ferrari 458 Italia

| Pjesë | Çmimi | Pesha e kursyer | Duket më mirë |

|---|

| Difuzori i pasëm | Çmime fabrike | 8 paund | ✓✓✓ |

| Funde anësore | Çmime fabrike | 6 paund | ✓✓✓ |

| Buzë e përparme | Çmime fabrike | 5 paund | ✓✓✓ |

| Kompleti i mbulesës së motorit | Çmime fabrike | 12 paund | ✓✓✓ |

| Mbulesa për dorezën e sediljeve | Çmime fabrike | 0,5 paund | ✓✓ |

Pjesët e jashtme që bëjnë ndikim të madh

Të karbonit fiber rear diffuser is our most popular part. It makes your car look like a race car from behind. It helps with airflow too.

Tona mbulesa e parakolpit të pasmë prej karboni përshtatet në mënyrë të përkryer me Ferrari 458 Italia dhe Spider tuaj. Ka të njëjtën formë si pjesa e fabrikës por duket shumë më mirë.

Dëshironi pamjen e plotë? Provoni këto pjesë:

Pjesët e brendshme që ju bëjnë të buzëqeshni

Sa herë që uleni në makinën tuaj, do të shihni tonën fibër karboni pjesë:

- Lopat e ndërrimit të fibrave të karbonit ndjehu mirë në duart e tua

- Mbulesa e grupit të instrumenteve me fibër karboni duket e mrekullueshme

- Mbulesa për dorezën e sediljeve me fibër karboni shtoni detaje të vogla

- Paneli AC me fibër karboni e bën vizën të veçantë

Pse fibra jonë e karbonit është më e mirë

Jo të gjitha fibrat e karbonit janë të njëjta. Ne përdorim vetëm metodat më të mira:

- Procesi i infuzionit me vakum me rrëshirë epoksi

- Formimi me autoklavë nën presion

- Rezistencë ndaj temperaturës së lartë testimi

- Endje e thjeshtë model që duket perfekt

Kompani të tjera përdorin fibër karboni të lirë që thyhet ose duket e rreme. Pjesët tona janë bërë si Aksesorë OEM Ferrari.

Rezultate të vërteta nga pronarët e Real Ferrari

Pronarët e Ferrarit që blejnë pjesët tona shohin rezultate reale:

"Ferrari im i vitit 2011 458 Italia u shit për $166,000 në ankand. Ky është $16,000 më shumë se çmimi normal!"

Të carbon fiber engine bay side panels get more looks than anything else on my car.

Si të zgjidhni fibrën e duhur të karbonit

Kur blini pjesë me fibër karboni për tuaj Pjesë me fibër karboni Ferrari 458 Italia, kërkoni:

- Fibër karboni parapreg me endje të thjeshtë (karboni jo i lirë)

- Përfundim transparent me shkëlqim që përputhet me pamjen e Ferrarit

- Pjesë të bëra vetëm për 458 Italia/Spider/Speciale

- Teknologjia e formimit me autoklavë (jo e vendosur me dorë)

Porositni Fibër Karboni të personalizuar sot

Ne bëjmë pjesë me fibër karboni me porosi për nevojat tuaja ekzakte. Ne mund të kopjojmë pjesët tuaja të aksioneve ose të bëjmë dizajne të reja.

Tona makinë me fibër karboni pjesët përshtaten me shumë makina, jo vetëm Ferrari. Bëjmë edhe pjesë për motoçikleta me fibër karboni përdorni.

Si të porosisni:

- Na tregoni se çfarë pjese ju nevojitet

- Dërgoni foto ose pjesën e vjetër

- Ne bëjmë një kopje të përsosur të karbonit

- Ne ju dërgojmë shpejt

Pse të punoni me ne?

- Ne bëjmë pjesë në fabrikën tonë

- Ne dërgojmë direkt tek ju - pa ndërmjetës

- Ne mund të bëjmë çdo pjesë që dëshironi

- Ne përdorim real teknologjia e formimit me autoklavë

- Pjesët tona përshtaten në mënyrë perfekte herën e parë

Merrni kuotën tuaj sot

Make your Ferrari 458 Italia stand out from all the rest. Get the look, feel, and speed of a true race car with our carbon fiber pjesët.

Na dërgoni me email sot: [email protected]

Mos vozitni një Ferrari stok. Drejtoni Ferrarin TUAJ.