Vai vēlaties, lai jūsu lidmašīnas lidot tālāk? Vai jums ir vajadzīgas daļas, kas ilgst ilgāk? Vai metāla sijas veido arī jūsu lidmašīnu smags?

Vecās metāla detaļas padara lidmašīnas smagas. Smagajām lidmašīnām vajag vairāk degvielas. Vairāk degvielas maksā vairāk naudas. Arī metāla detaļas var sarūsēt un salūzt.

Jūsu lidmašīnām ir jābūt gaisma bet stiprs. To ir grūti izdarīt ar veciem materiāliem.

Kāpēc tas kaitē jūsu uzņēmumam

Ja jūsu lidmašīnas ir pārāk smagas:

- Jūs tērējat pārāk daudz degviela

- Jūsu lidmašīnas nevar lidot kā tālu

- Ir nepieciešams salabot detaļas biežāk

- Jūs atpaliekat no citiem uzņēmumiem ar labākas lidmašīnas

Katru dienu, turpinot lietot smagās metāla detaļas, jūs zaudējat naudu. Jūsu lidmašīnas vairāk paliek uz zemes. Jūsu klienti izvēlas citus uzņēmumus.

Atbilde: mūsu oglekļa šķiedras C-sijas

Mēs izgatavojam oglekļa šķiedras C-sijas kas atrisina visas šīs problēmas! Mūsu sijas ir radītas tieši jums - pasūtījuma piemērots jūsu lidmašīnām.

Oglekļa šķiedras sijas ir 39% stiprāks nekā vecās sijas, bet daudz vieglākas. Tas nozīmē, ka jūsu lidmašīnas var:

- Lidot tālāk uz to pašu degvielu

- Nēsāt vairāk cilvēki vai lietas

- Vajag mazāk fiksēšana

- Palieciet gaisā ilgāk

Ar ko mūsu oglekļa šķiedras C sijas ir īpašas

Apskatiet, ko rāda mūsu testi:

| Ko mēs pārbaudām | Ko mēs atradām |

|---|

| Spēks | Līdz 39% stiprāks par vecām sijām |

| Svars | 60% vieglāks par metāla daļām |

| Cik ilgi tie ilgst | 3-5 reizes garāks par metālu |

| Laiks taisīt | Tikai 2,5-3 stundas vienai daļai |

| Kvalitāte | Mazāk nekā 1% trūkumi |

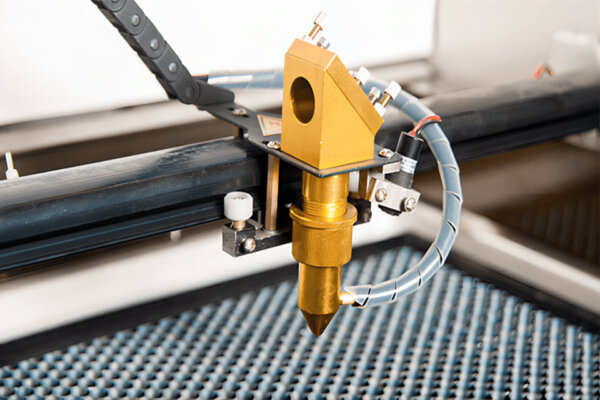

Kā mēs tos uzlabojam

Mūsu oglekļa šķiedras C-siju veicot soļus:

- Mēs izmantojam augšpusē šķiedras (piemēram, T700 oglekļa šķiedras)

- Mēs ievietojam šķiedras pareizā veidā, lai iegūtu lielāku spēku

- Mēs izmantojam īpašu līmi, kas nerada gaisa burbuļus

- Mēs uzkarsējam un nospiežam tieši pareizi

- Mēs pārbaudām katru staru pirms tā nosūtīšanas

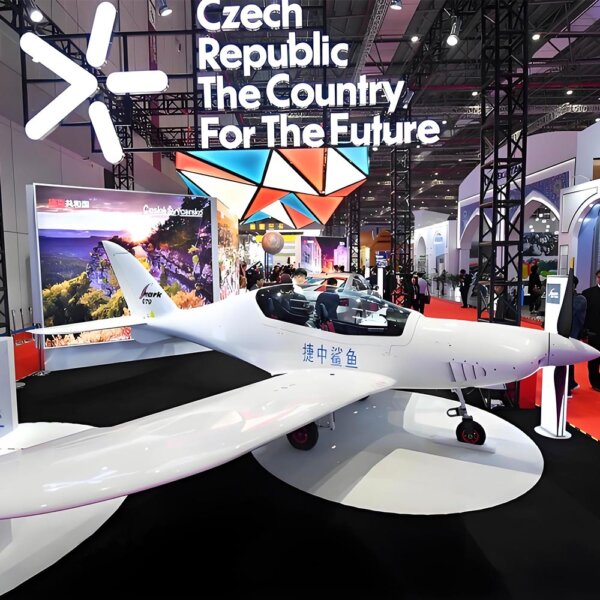

Kas izmanto mūsu C sijas

Mūsu sijas darbojas daudzās plaknēs:

- Lielas lidmašīnas kas lido cilvēkus

- Lidmašīna ar slīpa rotoru kas paceļas kā helikopters, bet lido kā lidmašīna

- Mazās lidmašīnas kam jābūt vieglam

- Droni kam jālido ilgi

Kāpēc izvēlēties mūsu uzņēmumu

Mēs neesam tikai jebkura rūpnīca. Mēs esam gatavojuši pielāgota oglekļa šķiedra daudzus gadus.

Mēs jums sniedzam:

- OEM/ODM pakalpojums - mēs izgatavojam to, kas jums nepieciešams

- Ātra izgatavošana – 2,5-3 stundas vienai daļai

- Ideāli piemērots – radīts tieši jūsu lidmašīnām

- Augstākā kvalitāte - mazāk nekā 1% trūkumi

- Labāk nekā citi – mūsu šķiedras stūrēšanas tehnoloģija padara sijas 19-39% stiprākas

Kā mūsu daļas palīdz jūsu uzņēmumam

Pērkot mūsu oglekļa šķiedras C sijas:

- Jūsu lidmašīnas izmanto mazāk degvielas (taupiet naudu)

- Jūsu lidmašīnas var lidot tālāk (padarīt klientus laimīgus)

- Jūsu daļas ir pēdējās ilgāk (mazāk remonta izmaksas)

- Jūsu lidmašīnas var pārvadāt vairāk (pelni vairāk naudas)

- Jūsu uzņēmums izskatās vairāk augsto tehnoloģiju (uzvarēt citus)

Kādas citas lietas mēs ražojam

Mēs izgatavojam ne tikai C veida sijas. Izgatavojam arī:

Kā pasūtīt no mums

Mūsu oglekļa šķiedras C siju iegūšana ir vienkārša:

- Pastāstiet mums kas jums nepieciešams

- Mēs sastādīt plānu un parādīs jums

- Tu saki jā

- Mēs izgatavot jūsu daļas

- Mēs pārbaudi katru daļu

- Mēs nosūtīt tos jums ātri

Klausieties no Happy Plane Makers

"Pēc šo C veida siju ievietošanas mēs samazinājām degvielas patēriņu par 15%." - Lielo lidmašīnu uzņēmums

"Mūsu lidmašīnas tagad darbojas 2 stundas ilgāk, izmantojot to pašu degvielu." - Mazo lidmašīnu izgatavotājs

"Daļas ir piemērotas pirmajā reizē. Vairs nav jāgaida uz labojumiem." - Dronu veidotājs

Zinātne aiz mūsu oglekļa šķiedras

Mūsu oglekļa šķiedra nav tāda kā citi. Mēs izmantojam:

- Šķiedru stūrēšana kas padara sijas 19-39% stiprākas

- Īpaša līme kas padara detaļas, kas neplīst

- Gudras mašīnas kas vislabāk ievieto šķiedras

- Uzkarsē un nospiediet tikai pareizi, lai izgatavotu perfektas detaļas

Sāciet lidot labāk jau šodien

Neļaujiet smagajām metāla daļām noturēt lidmašīnas uz zemes. Netērējiet vairāk naudas degvielai. Neatpaliek no citiem lidmašīnu ražotājiem.

Zvaniet mums šodien runāt par savām vajadzībām. Mēs izgatavosim perfektas oglekļa šķiedras C sijas jūsu lidmašīnām.

Apmeklējiet mūsu galvenā oglekļa šķiedras lapa lai redzētu visu, ko varam darīt jūsu labā!

Tagi: Gaisa kuģi elektrifikācija, Energoefektivitāte, Oglekļa emisiju samazināšana, Kompozītmateriāli, Strukturālais pastiprinājums, Vieglās aviācijas komponenti, eVTOL lidmašīnas, Ūdeņraža degvielas elementi, Kosmiskā inženierija, Oglekļa šķiedras kompozīti