Augstas kvalitātes kaltas oglekļa šķiedras sākumkomplekts augstas kvalitātes pielāgotām detaļām

Laipni lūgti pasaulē kaltas oglekļa šķiedras! Mūsu starta komplekts palīdz jums izveidot pārsteidzošas daļas automašīnām, lidmašīnām, sporta inventāram un daudz kam citam. Mēs esam viens no labākajiem pielāgota oglekļa šķiedra produktu ražošanas rūpnīca ar ilggadēju pieredzi labāko oglekļa detaļu ražošanā.

Kāpēc izvēlēties mūsu komplektu?

- Viegli lietojams - pat tad, ja esat iesācējs oglekļa šķiedras jomā.

- Augstākās kvalitātes materiāli - tāds pats kā luksusa automašīnās.

- Pilns atbalsts - mūsu komanda palīdz jums katrā solī

- Pielāgotas opcijas - izgatavot detaļas, kas precīzi atbilst jūsu vajadzībām.

- Ātra piegāde - sāciet darbu uzreiz

Kas ir kalta oglekļa šķiedra un kāpēc tā ir pārsteidzoša

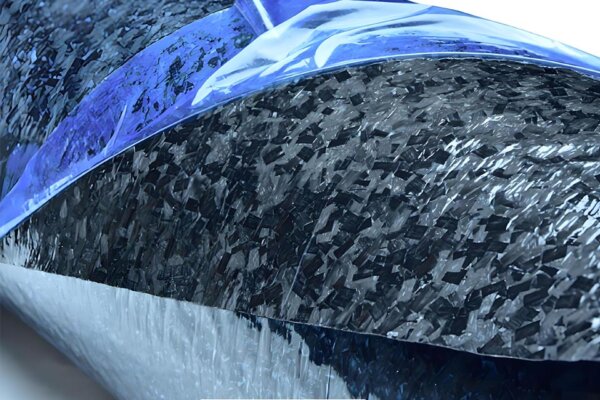

Kalta oglekļa šķiedra ir jauns veids lai izgatavotu oglekļa detaļas. Tā izmanto sasmalcināts ogleklis sajaukts ar sveķi lai izgatavotu izturīgas un labi izskatīgas detaļas. Atšķirībā no vecajām aust oglekļa šķiedras, kaltajam ogleklim ir foršs marmora izskats, kas patīk daudziem cilvēkiem.

The kalts ogleklis šķiedra process sākas ar sasmalcinātas oglekļa šķiedras kas sajaucas ar epoksīda sveķi. Tad mēs izmantojam karstums un spiediens lai izveidotu galīgo daļu. Tādējādi tiek izgatavotas detaļas, kas ir ļoti izturīgas, bet arī izskatās lieliski. Mūsu klienti aviācija, automobiļu nozare, un sporta inventārs patīk, ka kaltas oglekļa detaļas ir gan vieglas, gan izturīgas. Nejaušais modelis sasmalcinātas šķiedras kopā piešķir katram izstrādājumam vienreizēju izskatu, kas izceļas.

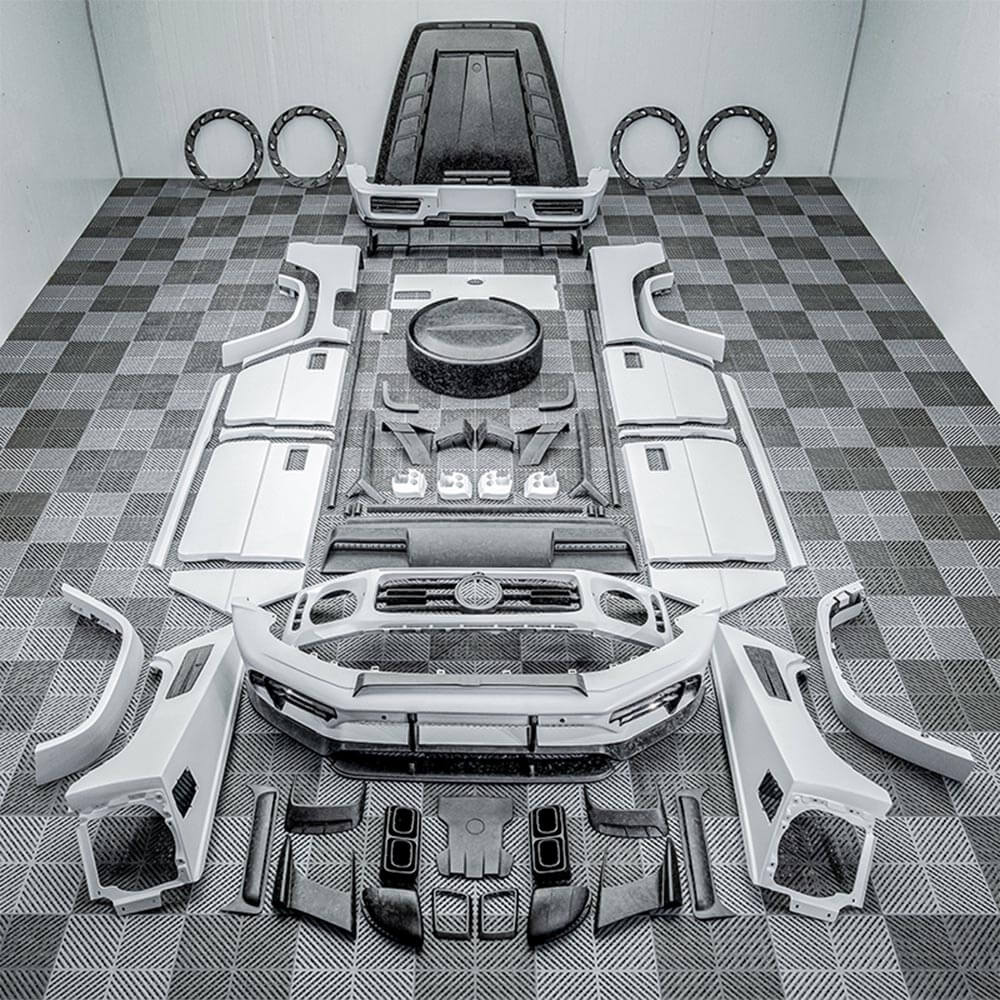

Pilns kalto oglekļa šķiedras izstrādes komplekta saturs

Mūsu sākuma komplekts ir viss nepieciešamais, lai sāktu kalti oglekļa šķiedras komponenti. Katrs komplektā ietilpst:

| Vienums | Daudzums | Mērķis |

|---|

| Sasmalcināta oglekļa Tow | 500g | Galvenais šķiedras materiāls |

| Premium klases epoksīdsveķi | 1L | Saistviela |

| Cietinātājs | 500 ml | Aktivizē sveķus |

| Atlaides vasks | 100g | Vieglai detaļu noņemšanai |

| Kompresijas veidne (paraugs) | 1 | Detaļu formēšanai |

| Norādījumu rokasgrāmata | 1 | Soli pa solim |

| Drošības cimdi | 2 pāri | Aizsardzība |

| Maisīšanas trauki | 5 | Sveķu sagatavošanai |

The kalts oglekļa šķiedras izstrādes komplekts ir paredzēta gan jauniem lietotājiem, gan profesionāļiem. Mūsu epoksīdsveķu sistēma ir tas pats, ko mēs izmantojam savā rūpnīcā, lai augstas veiktspējas daļas.

"Šis komplekts mainīja mūsu prototipu detaļu izgatavošanas veidu. Kvalitāte ir pārsteidzoša, un atbalsta komanda mums palīdzēja katrā solī." - John M., automobiļu dizaina inženieris

Kā izgatavot apbrīnojamus oglekļa šķiedras izstrādājumus

Pagatavošana kaltas oglekļa šķiedras detaļas ar mūsu komplektu ir viegli. Lūk, kā:

- Sajauc sveķus - Apvienojiet epoksīda sveķi un cietinātājs pa labi sveķu attiecība

- Oglekļa sagatavošana - Iegūstiet savu sasmalcināts ogleklis gatavs

- Materiālu kombinēšana - Sajauciet šķiedra un sveķi kopā labi

- Piepildiet veidni - Ievietojiet maisījumu savā presēšanas veidnes

- Piemērot spiedienu – Saspiest materiālu, lai atdalītu gaisu.

- Izārstēt - Ļaujiet tai sacietēt, pamatojoties uz mūsu rokasgrāmatu

- Pabeigt - Noņemiet un pulējiet gatavs kalts ogleklis daļa Jūs varat izmantot mūsu komplektu ar 3D drukāta veidne vai mūsu izgatavota divdaļīga presēšanas forma metāla. Abi lieliski noder cietais ogleklis daļas. Padomi labākajiem rezultātiem:

- Vienmēr izmantojiet izsmidzināmais atdalīšanas vasks jūsu veidnēs

- Sekojiet precīzam sveķu sistēma sajaukšanas instrukcijas

- Vienmērīgi piespiediet, kad izmantojot saspiešanas tehnika

- Slīpēšana un pulēšana, lai spīdīgi kalti pabeigt

Mūsu kalto oglekļa materiālu tehniskās specifikācijas

Mūsu īsta oglekļa šķiedra materiāliem nodrošina izcilas mehāniskās īpašības. visu veidu projektiem:

- Stiepes izturība: 3500 MPa

- Blīvums: 1,6 g/cm³

- Karstumizturība: Līdz 180°C

- Sveķu saturs: 40% pēc svara

- Šķiedras garums: 25 mm sasmalcināta vilkšana

- Izārstēšanas laiks: 24 stundas istabas temperatūrā vai 4 stundas 80°C temperatūrā. oglekļa šķiedras gabali mūsu komplektā ir sagriezti ideālā izmērā, lai tos būtu viegli izkārtojums un labāko izturību. Mūsu sveķu liešana sistēma darbojas gan ar saspiešanas formēšana cietā masā metodes un iespiests ar sveķiem daļas.

Nozares, kas mīl mūsu kalto oglekļa šķiedru

Mūsu oglekļa šķiedras izstrādājumi tiek izmantoti daudzās vadošajās nozarēs:

- Automašīnas un motocikli

- Informācijas paneļa daļas

- Korpusa paneļi

- Iekšējā apdare

- Aviācija

- Kabīnes sastāvdaļas

- Nekonstruktīvās daļas

- Pielāgotie ķermeņi

- Sporta aprīkojums

- Golfa klubu galvas

- Velosipēdu komponenti

- Tenisa rakešu daļas

- Medicīniskais aprīkojums

- Attēlveidošanas iekārtu korpusi

- Protēžu sastāvdaļas

- Viegli pārvietošanās palīglīdzekļi

- Plaša patēriņa elektronika

- Telefonu maciņi

- Portatīvo datoru pārvalki

- Skaļruņu korpusi

The formēšanas process mēs izmantojam detaļas, kas izskatās lieliski un labi darbojas. Kad oglekļa šķiedras tiek nospiesti kopā ar labo sveķu daudzums, viņi ražo daļas, kas ir labākas nekā parastās lamināts ogleklis.

Kāpēc izvēlēties mūsu kalto oglekļa šķiedru, nevis tradicionālās metodes?

| Funkcija | Kalts ogleklis | Tradicionālais aušana | Vienvirziena |

|---|

| Paskaties | Marmora raksts | Regulāra pinuma audums | Taisnas līnijas |

| Spēks | Ļoti augsts | Augsts | Visaugstākais vienā virzienā |

| Lietošanas ērtums | Vieglākais | Vidēja | Visgrūtāk |

| Atkritumi | Ļoti zems | Vidēja | Augsts |

| Izliekumi | Lieliski | Ierobežots | Ierobežots |

| Izmaksas | Vidēja | Augsts | Augstākā |

Kad jūs pirkt kaltas oglekļa šķiedras no mums jūs saņemat materiālus, ar kuriem ir viegli strādāt. Atšķirībā no vienvirziena ogleklis vai prepreg materiāliem, mūsu kaltais ogleklis ir elastīgāks sarežģītām formām.

Mūsu CT12 sasmalcinātas oglekļa šķiedras sistēmu var ievieto veidnē gandrīz jebkuras formas. Tas padara to ideāli piemērotu sarežģītu detaļu izgatavošanai, ko būtu grūti veikt ar parasto aust oglekļa šķiedras.

Mūsu kaltā oglekļa procesa priekšrocības:

- Mazāk atkritumu nekā ar tradicionālajām metodēm

- Ātrāks ražošanas laiks

- Labāk piemērots sarežģītām formām

- Katrai daļai ir unikāls izskats

- Spēcīgāka vairākos virzienos

Mēs izmantojam to pašu kalšana paņēmienus kā luksusa automobiļu ražotāji, bet izmantojiet tos savos projektos. Mūsu kompozītmateriāli ir pārbaudīti, lai atbilstu visaugstākajiem standartiem.

Klientu veiksmes stāsti

Mūsu oglekļa šķiedras daļas ir palīdzējuši daudziem uzņēmumiem:

"Mēs pārgājām uz kaltu oglekli mūsu motociklu detaļām, un pārdošanas apjomi pieauga 30%. Klientiem patīk unikālais izskats." - Mike T., Custom Motorcycle Shop

"Ar šo sistēmu izgatavotās kosmiskās aviācijas detaļas izturēja visus mūsu testus. Svara ietaupījums ir pārsteidzošs." - Sāra L., aviācijas un kosmosa piegādātāja

Mūsu sporta aprīkojuma līnija ieguva milzīgu izaugsmi, kad mēs pievienojām kaltas oglekļa šķiedras iespējas." - Deivids K., sporta aprīkojuma ražotājs

Strādājot ar mūsu kalti oglekļa šķiedras komponenti, jūs pievienojaties uzņēmumiem, kas augstu vērtē kvalitāti un inovācijas. Mūsu XCR pārklājuma sveķi nodrošina detaļām ilgmūžīgu apdari.

Kā pasūtīt pielāgotus oglekļa šķiedras risinājumus

Gatavs sākt veidot pārsteidzošu kaltas oglekļa šķiedras detaļas? Lūk, kā pasūtīt:

- Sazinieties ar mūsu komandu - Pastāstiet mums par savu projektu

- Saņemiet pielāgotu piedāvājumu - Izveidosim jūsu vajadzībām atbilstošu pakotni.

- Saņemiet savu komplektu - Ātra piegāde visā pasaulē

- Sāciet veidot - Ar mūsu pilnīgu atbalstu

Lielākiem projektiem mēs piedāvājam pilnu pielāgota oglekļa šķiedra produkts ražošana. Mūsu rūpnīca var izgatavot detaļas no mazām līdz ļoti lielām, izmantojot mūsu modernās presēšanas veidnes un ekspertu komanda.

Pasūtījuma iespējas:

- Sākuma komplekti testēšanai un mācībām

- Pielāgotu veidņu izveide

- Pilnas ražošanas sērijas

- Tikai materiālu iepakojumi

- Apmācība un atbalsts

Negaidiet, lai ražot oglekli detaļas, kas pārsteigs jūsu klientus. Mūsu kalts oglekļa šķiedras izstrādes komplekts ir pirmais solis, lai radītu izteiksmīgas detaļas. Sazinieties ar mums jau šodien, lai pievienotos oglekļa šķiedras revolūcijai!

Kopsavilkums: Mūsu augstākās kvalitātes kaltais ogleklis Šķiedras starta komplekts ir viss nepieciešamais, lai radītu satriecošas, profesionālas kvalitātes oglekļa detaļas. Pateicoties marmoram līdzīgajam izskatam, izcilajai izturībai un mūsu ekspertu atbalstam, jūs ātri vien izgatavosiet pārsteidzošas pielāgotas detaļas automobiļu, kosmosa un citām vajadzībām.