The Problem: Plain Carbon Fiber Doesn’t Always Match Your Style

Do you have carbon fiber parts that don’t match your style? Many people love the strong and light parts made of carbon fiber. But the black weave look isn’t always what you want.

Maybe you have:

- A carbon fiber bike frame that doesn’t match your team colors

- Carbon fiber car parts that clash with your paint job

- Custom carbon fiber items that need to blend with other parts

The plain black look of carbon fiber can be a real problem when you want all your parts to look the same.

Why This Matters: Unpainted Carbon Fiber Can Hurt Your Project

When your carbon fiber parts don’t match, it can make your whole project look bad. The black weave pattern stands out too much. It can make your car, bike, or other items look unfinished.

Plus, bare carbon fiber can get damaged by the sun. UV rays break down the epoxy resin over time. This can make your expensive parts get weak and ugly.

And here’s something many people don’t know – plain carbon fiber shows every little scratch. One small mark can ruin the look of your whole part!

The Solution: We Can Paint Your Carbon Fiber Parts Perfectly

Good news! As a carbon fiber manufacturer with 28+ years of experience, we can paint your carbon fiber to match any style you want. Our OEM/ODM custom services include expert painting that lasts.

We do the hard work for you:

- Clean the surface just right

- Sand with special tools that don’t damage the fibers

- Use special primers made for carbon fiber

- Apply the perfect paint in thin, even coats

- Finish with UV-resistant clear coat for lasting protection

Let’s look at the whole process in more detail.

Understanding Carbon Fiber Painting: What You Need to Know

What Makes Carbon Fiber Special?

Carbon fiber isn’t like metal or plastic. It has a glossy surface with epoxy resin coating the fibers. This makes it hard for regular paint to stick.

The carbon fiber weave pattern looks cool, but can show through paint if not done right. The fiber orientation matters too – some parts might need special painting steps.

Why Paint Your Carbon Fiber Parts?

There are big benefits to painting carbon fiber:

| Benefit | What It Means For You |

|---|

| Better Look | Match any color scheme for your car or bike |

| UV Protection | Stop sun damage that weakens parts |

| Hide Repairs | Cover up scratches or damage |

| Custom Style | Stand out with unique colors and effects |

How We Paint Carbon Fiber: Our Expert Process

Step 1: Surface Preparation

The most important step! Bad prep causes 90% of paint failures on carbon fiber.

Our process:

- Clean with special degreaser solvents

- Remove all surface contaminants

- Use special abrasive pads that won’t damage the fibers

- Create the perfect surface roughness for paint to grip

Step 2: Primer Application

We use special primer made for carbon fiber:

- High-build primer fills tiny holes

- Creates strong paint adhesion

- Prevents the carbon fiber weave from showing through

- Ensures paint bonding that lasts for years

Step 3: Paint Selection and Application

We use only the best paints for carbon fiber:

- Polyurethane paint for cars and motorcycles

- Acrylic paint for parts that need to flex

- Two-part epoxy paint for the strongest finish

Our experts apply thin coat application in many layers, with perfect paint curing between each coat.

Step 4: Clear Coat and Finishing

The final step for perfect protection:

- UV-resistant clear coat prevents sun damage

- Wet sanding for a glass-smooth finish

- Paint polishing for show-quality shine

- Final paint finish inspection to ensure perfection

Why Our Painting Process Is Better

Many shops try to paint carbon fiber but make big mistakes:

- They skip proper surface cleaning

- They use wrong paint types

- They don’t understand epoxy reaction with certain paints

- They don’t know how to prevent paint peeling

With 28+ years experience, we know all the tricks to make paint stick to carbon fiber perfectly. Our OEM/ODM background means we’ve solved every carbon fiber painting problem.

Types of Carbon Fiber We Paint

We can paint any type of carbon fiber parts:

Automotive Carbon Fiber

Our team specializes in carbon fiber car parts with perfect paint:

- Carbon fiber hoods ($500-$1500 to paint professionally)

- Carbon fiber spoilers

- Carbon fiber fenders ($300-$600 to paint)

- Carbon fiber interior trim

- Automotive panels with complex curves

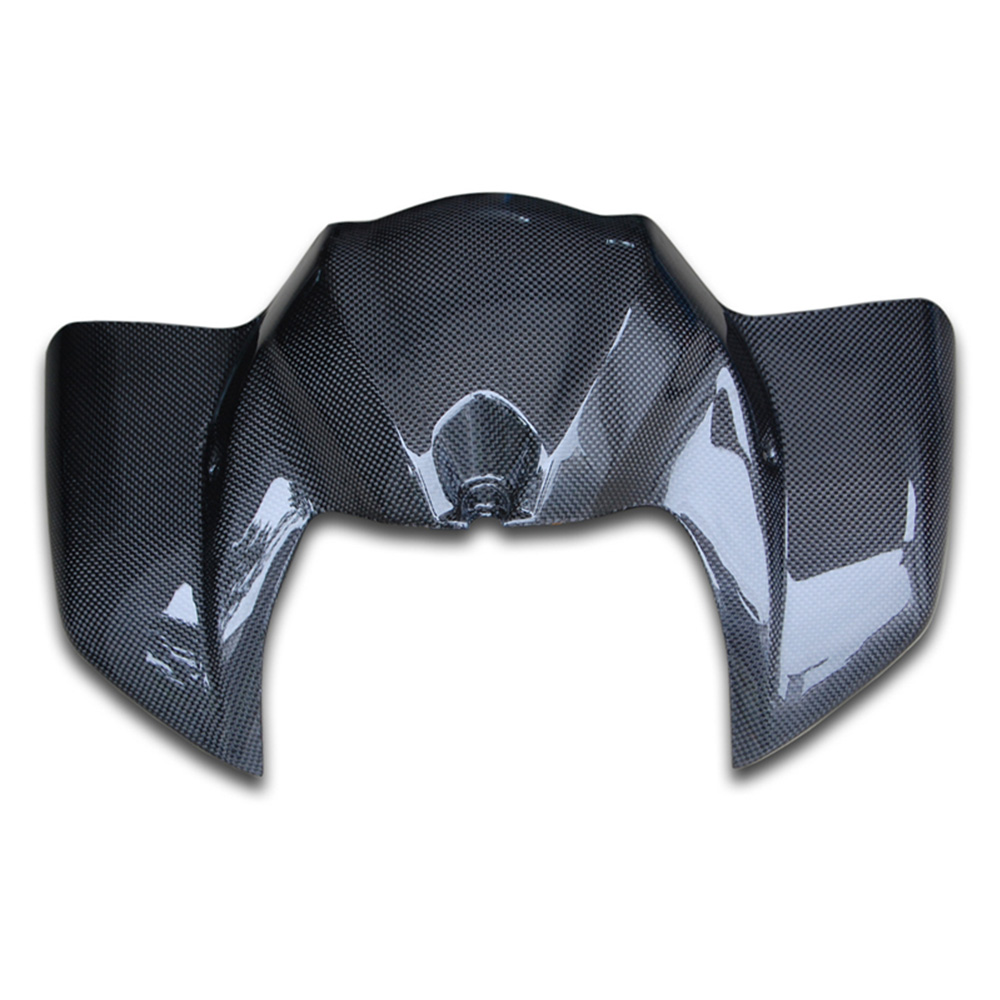

Motorcycle Carbon Fiber

We create stunning carbon fiber motorcycle parts:

- Painted gas tanks

- Fenders with perfect color match

- Side panels with custom designs

- Windscreens with special coatings

Sports Equipment

Our painting works great for:

- Bicycle frames with team colors

- Carbon fiber helmets with custom graphics

- Carbon fiber kayaks with bright colors

- Carbon fiber drone frames that match your brand

Paint Finishes We Offer

We can create any look you want:

| Finish Type | Best For | Special Features |

|---|

| High-gloss finishes | Show cars, display items | Mirror-like shine, shows off curves |

| Matte finishes | Modern sport bikes, tactical gear | No glare, hides small flaws |

| Satin | Luxury items, high-end bikes | Subtle shine, elegant look |

| Custom effects | Show vehicles, one-off projects | Color-shifting, metallic, pearl |

Cost Comparison: DIY vs. Professional vs. Our OEM Service

| Service Type | Cost Range | Quality | Durability |

|---|

| DIY Painting | $50-$200 | Low-Medium | 1-2 years |

| Local Body Shop | $300-$1500 | Medium | 2-5 years |

| Our OEM Service | Call for quote | Professional | 5-10+ years |

Our factory-direct service often costs less than local shops while providing better quality. As a carbon fiber manufacturer, we control the whole process.

Common Problems When Painting Carbon Fiber (And How We Solve Them)

Problem: Paint Doesn’t Stick

This happens when shops don’t understand surface preparation for carbon fiber.

Our solution: We use special primer adhesion techniques developed over 28 years.

Problem: Weave Shows Through Paint

The carbon fiber weave can create a “print-through” effect in paint.

Our solution: We use special high-build primer and multi-layer painting techniques.

Problem: Paint Cracks or Peels

This happens when the wrong paint is used or when paint flexibility doesn’t match the part.

Our solution: We select the perfect paint for each specific application.

Our Custom Carbon Fiber Painting Process In Action

Let’s see a real example of our work:

Customer Problem: A racing team had carbon fiber bike parts that didn’t match their team colors.

Our Process:

- Tested the parts for material compatibility

- Created custom paint to match exact team colors

- Applied special flexible paint system

- Added extra UV protection for outdoor racing

- Finished with anti-chip coating

Result: Perfect color match that’s still looking great after 3 racing seasons!

- 28+ years experience working with carbon fiber

- OEM/ODM manufacturer with full quality control

- Factory-direct pricing without middlemen

- Perfect paint adhesion that lasts for years

- Any color or finish you can imagine

How Our Carbon Fiber Manufacturing Experience Makes Better Painted Parts

As a carbon fiber maker, we understand the material better than paint shops. We know:

- How epoxy resin reacts with different paints

- How to work with different fiber orientation

- The right surface preparation for each type of carbon

- How to avoid damaging the structural integrity

This means our painted parts look better and last longer.

Ready For Perfect Painted Carbon Fiber Parts?

Don’t settle for plain black carbon fiber that doesn’t match your style. And don’t risk painting it yourself or using a shop without carbon fiber experience.

Our 28+ years as an OEM/ODM carbon fiber manufacturer means we can create exactly what you need. From cars to bikes to custom items, we make carbon fiber parts that look perfect.

Visit our website at chinacarbonfibers.com to see our work and contact us for a free quote on your painted carbon fiber project.

We’ll help you solve the problem of mismatched carbon fiber parts with our expert painting services!