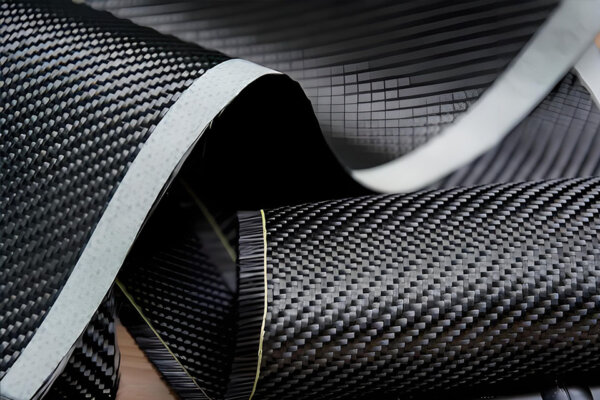

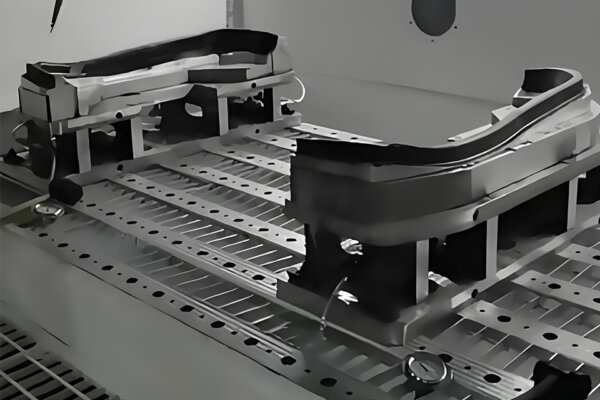

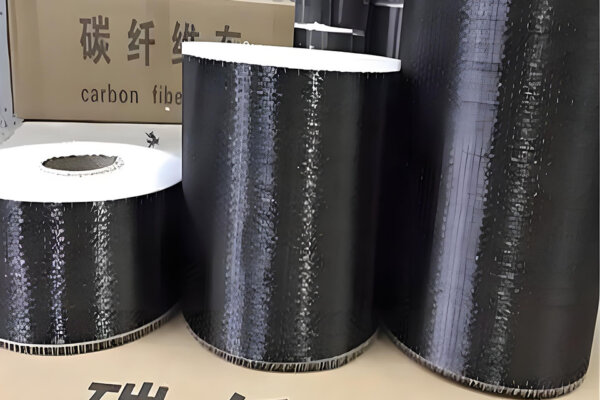

Koolstofvezelcomposietmateriaal Warmpersvormproces

Onze fabriek maakt gebruik van een geavanceerd koolstofvezel-warmpers-proces met een P20-stalen mal, wat een hoge efficiëntie, precisie, duurzaamheid en kosteneffectiviteit voor kwaliteitsproductie garandeert.