Hoe koolstofvezelplaten te snijden: de juiste manier voor de beste resultaten

Het probleem: koolstofvezel snijden is moeilijk

Probeert u koolstofvezelplaten te snijden maar krijgt u slechte resultaten? Veel mensen hebben dit probleem. Koolstofvezel is erg sterk, maar kan verkeerd breken als u het snijdt.

Slechte sneden verspillen je geld. Ze laten je onderdelen er slecht uitzien. Ze kunnen je zelfs pijn doen met kleine stofdeeltjes die in je longen terechtkomen.

Waarom is het zo moeilijk?

- Koolstofvezel kan splijten

- Het produceert gevaarlijk stof

- Normaal gereedschap wordt snel bot

- Slechte sneden verpesten dure materialen

De pijn wordt erger

Als je de verkeerde gereedschappen gebruikt, kan het snel misgaan:

- Je project krijgt lelijke randen als je niet de juiste snijplotter gebruikt.

- Je verspilt geld aan materialen

- Je zou slecht stof kunnen inademen

- Je gereedschap gaat kapot

Onze fabriek ziet dit de hele tijd. Mensen proberen geld te besparen met goedkope gereedschappen. Maar uiteindelijk geven ze meer uit om fouten te herstellen.

Het goede nieuws: we weten hoe we het kunnen oplossen

Met 28+ jaar ervaring in het maken van koolstofvezelonderdelen, wij kennen alle trucs. Onze aangepaste CNC koolstofvezel experts kunnen helpen. Of we kunnen u laten zien hoe u het zelf kunt doen.

Laten we uw problemen met het snijden van koolstofvezels oplossen!

Gereedschappen die u nodig hebt voor perfecte sneden

Kies het juiste gereedschap voor uw klus:

| Gereedschapstype | Goed voor | Kosten | Vaardigheidsniveau |

|---|---|---|---|

| CNC-machine | Grote klussen, perfecte sneden | $$$$ | Pro |

| Diamant natte zaag | Middelgrote vellen | $$$ | Medium |

| Decoupeerzaag met koolstofzaagblad | DIY-projecten | $$ | Eenvoudig |

| Dremel-gereedschap | Kleine, bochtige sneden | $ | Eenvoudig |

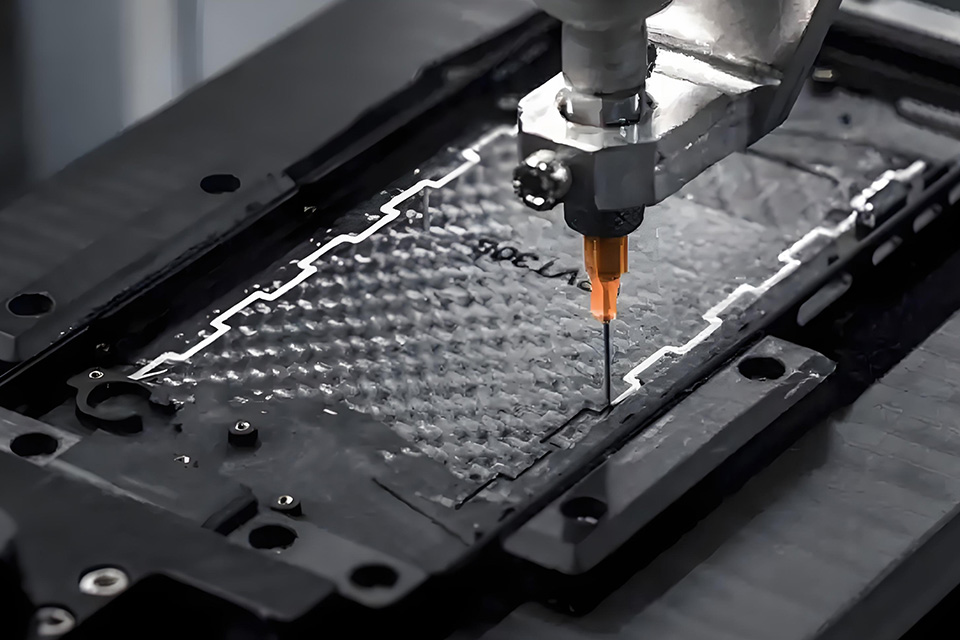

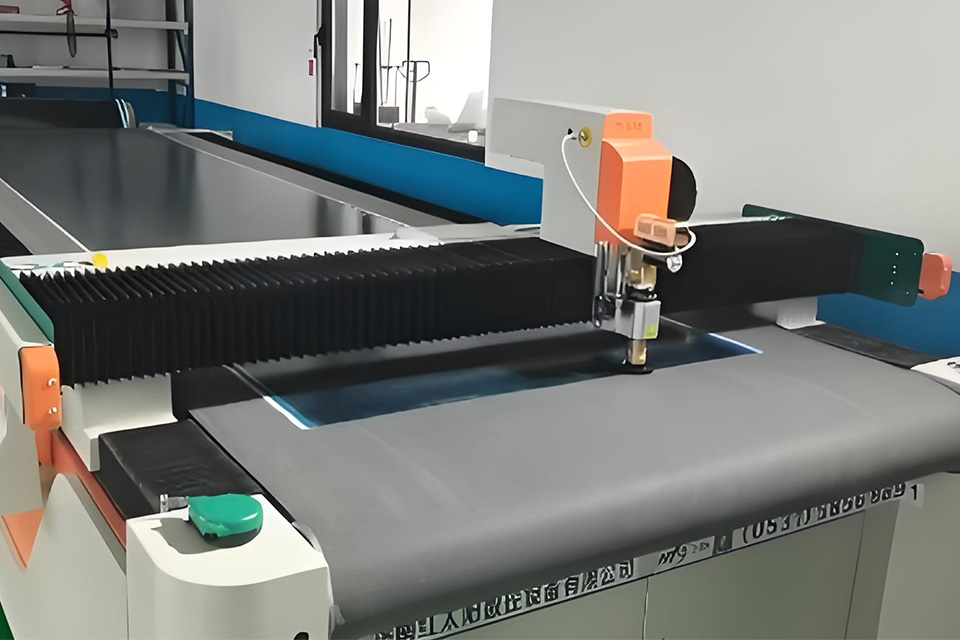

1. CNC voor perfecte sneden

CNC-snijden is het beste voor grote klussen. Onze fabriek gebruikt AMOR CNC-machines met hardmetalen snijmachines.

- Trillingssnijkoppen

- Stofbeheersingssystemen

- Computer perfecte sneden

Professionele tip: CNC-machines snijden met 10.000 toeren per minuut voor platen van 1/16 inch en met 60 inch per minuut voor de beste resultaten.

2. Diamant natte zagen

Water houdt stof tegen en helpt bij het maken van schone sneden in laminaat. Goed voor:

- Middelgrote vellen

- Rechte lijnen

- Minder stofproblemen

3. Decoupeerzagen van koolstofvezel

Bosch maakt goede koolstofvezelbladen die:

- Gaan 10 keer langer mee dan gewone mesjes

- Maak schonere sneden

- Kost minder dan grote machines

4. Handgereedschap voor kleine klusjes

Voor kleine werkzaamheden of aangepaste koolstofvezel onderdelen:

- Scheermesjes (alleen dunne vellen)

- Dremel met metaalsnijbits

- Vijlen en schuurpapier voor randen

Stap-voor-stapgids voor perfecte sneden

Stap 1: Maak je klaar

Voordat u gaat snijden:

- Draag veiligheidsuitrusting

- Stofmasker (N95 of beter)

- Veiligheidsbril

- Handschoenen

- Markeer uw sneden

- Gebruik een liniaal

- Markeer met een pen

- Meet twee keer!

- Stofbeheersing instellen

- Werk buiten als je kunt

- Gebruik een stofzuiger

- Houd het gebied schoon

Stap 2: Kies hoe u wilt snijden

Voor handgereedschap:

- Gebruik een achterwand onder uw laken

- Ga langzaam en gestaag

- Snijd met de vezelrichting mee als je kunt

Voor elektrisch gereedschap:

- Stel de juiste snelheid in (zie onze tabel)

- Klem je laken goed vast

- Laat het gereedschap het werk doen – duw niet te hard

Snijsnelheidstabel

| Plaatdikte | Gereedschapssnelheid | Voedingssnelheid | Beste voor |

|---|---|---|---|

| 1/32″ (0,8 mm) | 10.000 toeren per minuut | 70 inch/minuut | Kleine onderdelen |

| 1/16″ (1,6 mm) | 10.000 toeren per minuut | 60 inch/minuut | De meeste banen |

| 1/4″ (6,35 mm) | 8.000 toeren per minuut | 40 inch/minuut | Grote onderdelen |

Stap 3: Maak je keuze

De juiste manier:

- In één vloeiende beweging gesneden

- Zorg voor een gelijkmatige druk

- Volg je sporen

- Ga met de vezelrichting mee

Verkeerde manieren die problemen veroorzaken:

- Te hard duwen

- Te snel gaan

- Gebruik van botte gereedschappen

- Tegen de draad in snijden

Stap 4: De randen repareren

Na het snijden:

- Schuur ruwe randen (120 korrel, dan 400 korrel)

- Maak het stof schoon met lucht of een borstel

- Dicht de snijranden indien nodig af met hars

Veelvoorkomende problemen en hoe u ze kunt oplossen

Probleem: Randen breken en splinteren

Dit gebeurt met 65% aan zelfgemaakte koolstofvezels!

Herstel het:

- Gebruik fijnere tandbladen

- Langzamer snijden

- Ga met de vezelkorrel mee

- Gebruik achtergrondmateriaal

Probleem: Te veel stof

Stof is slecht voor uw gezondheid en uw werkplek.

Herstel het:

- Gebruik nat zagen wanneer dat mogelijk is

- Draag een goed masker

- Gebruik vacuümsystemen

- Werk in de open lucht om blootstelling aan koolstofvezelstof tot een minimum te beperken.

Probleem: Gereedschappen worden snel bot

Koolstofvezel is erg schadelijk voor gereedschap, vooral voor schurende gereedschappen.

Herstel het:

- Gebruik diamantgereedschap

- Vervang de messen vaker

- Gebruik gereedschap dat is gemaakt voor koolstofvezel

- Laat ons het zware werk doen!

Waarom onze fabriek kan helpen

Met 28+ jaar bezig met het maken van koolstofvezel onderdelen, wij kennen elke truc.

Onze fabriek heeft:

- Industriële CNC-machines met hardmetalen frees

- Deskundige technici

- Stofbeheersingssystemen

- Elke keer perfect snijden

Wij maken onderdelen voor:

- Koolstofvezel auto onderdelen

- Motorfiets van koolstofvezel componenten

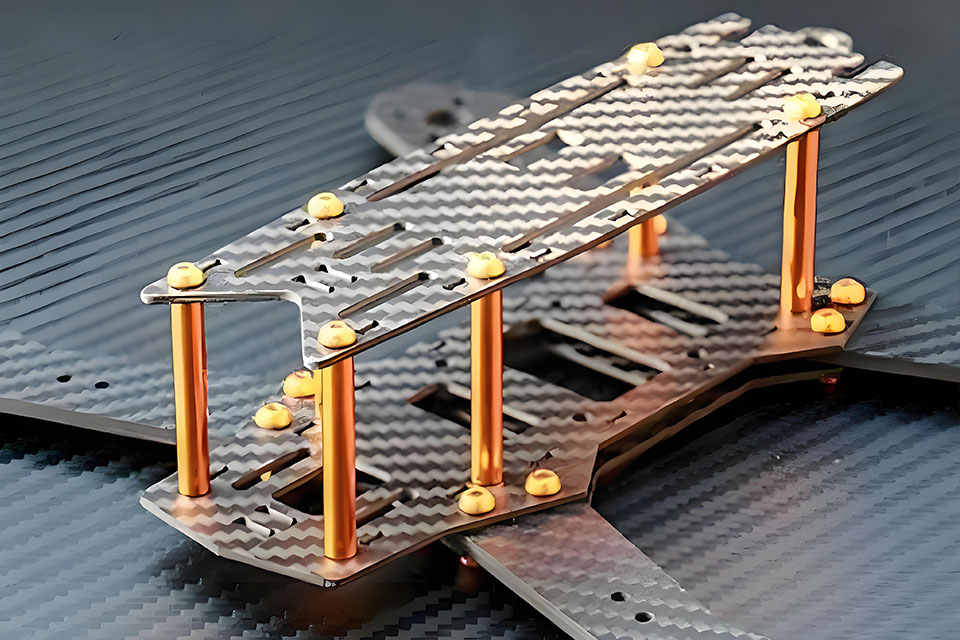

- Drone-frames

- Aangepaste projecten

Gereedschappen die we gebruiken versus doe-het-zelfopties

| Gereedschapstype | Onze fabriek | DIY-optie | Resultaten |

|---|---|---|---|

| CNC-freesmachine | $5.000+ apparaten | – | Perfecte sneden |

| Diamantzagen | Industriële kwaliteit | $300-800 thuismodellen | Goede sneden |

| Speciale messen | Professioneel | $50-200 | Oké bezuinigingen |

| Handgereedschap | Zelden nodig | $20-50 | Basis sneden |

Waarom zou u uw koolstofvezel door ons laten snijden?

Problemen met doe-het-zelf snijden:

- Gereedschappen kosten veel

- Leren kost tijd

- Fouten afvalmateriaal

- Stof is slecht voor de gezondheid

Voordelen van onze service:

- Altijd perfecte sneden, zelfs bij laminaat.

- Geen gereedschapskosten voor u

- Geen gezondheidsrisico's

- Snelle doorlooptijd

- 28+ jaar ervaring

Onze OEM/ODM-diensten

Wij snijden niet alleen koolstofvezel. Wij maken volledige onderdelen:

- Wij ontwerpen met u

- Wij maken prototypes

- Wij doen de volledige productie

- Wij verzenden wereldwijd

Onze sterke punten:

- 28+ jaar koolstofvezel maken

- ISO-gecertificeerde fabriek

- Maatwerk is welkom

- Eén loket

Echte klantproblemen die we hebben opgelost

Case 1: Raceteamonderdelen

Probleem: Team had behoefte aan aangepaste onderdelen met perfecte sneden

Wat we deden:

- CAD-ontwerpen gemaakt

- Gesneden met CNC-precisie

- Alle randen zijn afgewerkt om een gladde snijlijn te garanderen.

- Raceklare onderdelen geleverd

Resultaat: De auto was 3,2 seconden sneller per ronde!

Geval 2: Problemen met dronemakers

Probleem: Zelfgemaakte sneden waren ongelijk en braken

Wat we deden:

- Gemaakte mallen voor perfecte sneden

- Gebruikte diamantbladen

- Alle randen afgedicht

Resultaat: Droneframes gingen 5x langer mee!

Bent u klaar voor perfecte koolstofvezelonderdelen?

Optie 1: Wij maken het voor u

Laat onze experts alles regelen. Krijg perfecte onderdelen zonder gedoe.

Optie 2: Wij snijden, u maakt af

Wij doen het zware snijwerk, jij doet de eindmontage.

Optie 3: Leer onze methoden kennen

Wij kunnen onze kennis van meer dan 28 jaar delen.

Gereedschappen die u zou moeten hebben

Als u zelf koolstofvezel wilt snijden, hebt u de volgende gereedschappen nodig:

Onmisbare veiligheidsuitrusting:

- N95-masker of -beademingsapparaat

- Veiligheidsbril

- Handschoenen

Basis snijgereedschappen:

- Bosch koolstofvezel decoupeerzaagblad

- Dremel met metaalsnijbits

- Fijn schuurpapier (korrel 120-400)

Voor betere resultaten:

- Diamant natte zaag

- Stofafzuigsysteem

- Klemsysteem

Laatste gedachten

Koolstofvezel snijden kan lastig zijn. Maar met de juiste gereedschappen en knowhow kun je goede resultaten behalen.

Of maak het uzelf gemakkelijk: laat onze fabriek met 28+ jaar ervaring doen het voor u! Wij snijden koolstofvezel de hele dag, elke dag.

Neem contact met ons op nu voor een gratis offerte voor uw koolstofvezel snijbehoeften!