Сделайте свой Yamaha R6 лучше с помощью воздухозаборников из углеродного волокна

У вас есть Yamaha R6? грустно о том, как это выглядит? пластик Воздухозаборники, которые идут в комплекте с вашим велосипедом, выглядят не круто. Они легко ломаются. Они нагреваются. Они делают ваш велосипед похожим на все остальные велосипеды.

Это плохой для вас, если вы хотите:

- Сделайте свой велосипед лучше

- Заставьте свой велосипед ехать быстрее

- Держите свой велосипед в прохладе

- Выделяйтесь среди других гонщиков

Почему это бесит водителей

Когда ваши стандартные вентиляционные отверстия нагреваются, они могут таять. Это не безопасно. Ваш велосипед перегревается. Он замедляется. Он быстро стареет.

Другие гонщики проносятся мимо вас с крутыми детали из углеродного волокна. Их велосипеды выглядят лучше. Их велосипеды остаются кулер. Их велосипеды едут Быстрее.

Вы потратили кучу денег на свой R6. Но он все еще выглядит как любой другой R6 на дороге. Это не честно тебе.

Мы можем устранить проблемы с вентиляцией

Мы делаем лучший Воздухозаборники из углеродного волокна Yamaha R6. Наши детали решат все ваши проблемы одной простой заменой!

Наши воздухозаборники из углеродного волокна:

- Сильнее чем пластик

- Зажигалка чем стандартные детали

- Лучше выглядит с крутыми узорами переплетения

- Охладитель работает для вашего двигателя

- Сделано специально для вас с индивидуальными опциями

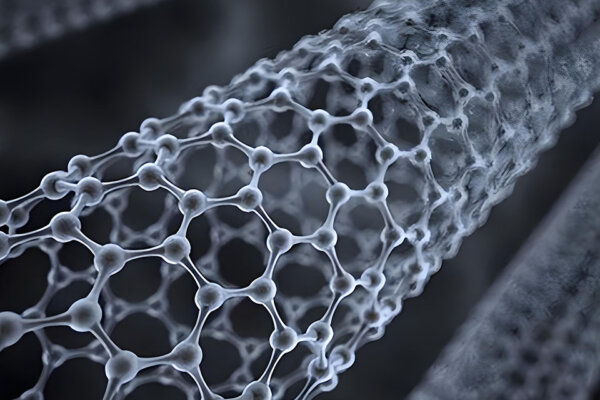

Что делает наше углеродное волокно особенным

Мы используем такой же методы как топовые бренды. Мы используем TORAYCA® ПРЕПРЕГ углеродное волокно из Японии. Это хорошие вещи.

Мы отверждаем наши детали в автоклав при высокой температуре и давлении. Это делает их:

- Очень сильный

- Никаких пузырьков воздуха.

- Идеально подходит

- Долгоиграющий

Детали для каждой модели Yamaha R6

| R6 Год | Что мы делаем | Главные особенности |

|---|

| 2003-2005 | Крышки воздуховодов | Матовая или глянцевая отделка, карбон 100% |

| 2006-2007 | Воздуховоды | Автоклавное отверждение, премиум TORAYCA® |

| 2008-2016 | Воздухозаборники | Варианты полотняного или саржевого переплетения |

| 2017+ | Крышки воздухозаборников | Гоночный вид, прямая замена |

Все наши детали подходят идеальный в первый раз. Никакой резки. Никакой суеты. Просто прикрутите и вперед!

Почему райдеры любят наши воздухозаборники из углеродного волокна

Наш мотоцикл из углеродного волокна части делают гонщиков счастливыми. Вот почему:

Выглядеть лучше

Ваш велосипед будет выглядеть удивительный. Углеродное волокно имеет глубокий, богатый рисунок, который пластик не может сравниться. Люди будут останавливаться чтобы осмотреть свой велосипед.

Оставайтесь в прохладе

Наши вентиляционные отверстия пропускают больше воздуха к вашему двигателю. Это позволяет ему кулер. Более холодный двигатель работает лучше и служит дольше.

Иди быстрее

Углеродное волокно - это легче чем пластик. Меньше веса — больше скорости. Каждый грамм имеет значение, когда хочешь ехать быстро!

Прослужит дольше

Наши детали не трескаются и не выцветают. Защита от ультрафиолета сохраняет их внешний вид. новый в течение многих лет.

Какие варианты углеродного волокна вы можете выбрать?

Мы даем вам больше выбора чем другие компании:

- Саржевое плетение: Классический карбоновый вид с диагональным рисунком

- Полотняное переплетение: Более простой узор в виде шахматной доски

- Кованый карбон: Современный рисунок, имитирующий мрамор.

- Матовая отделка: Никакого блеска, скрытый вид

- Глянцевая отделка: Блестящий, выставочный вид

- Варианты цвета: Добавьте красные, синие или оранжевые выделения за +15% стоимость

Как мы производим лучшее углеродное волокно, чем другие

Наш завод использует 6-шаговый процесс для изготовления идеальных деталей:

- Дизайн: Мы сканируем настоящие детали R6 для идеальной подгонки

- Резать: Мы точно режем карбоновые листы TORAYCA®

- Класть: Мы вручную и с осторожностью укладываем углерод в формы

- Излечивать: Мы используем давление в автоклаве до 6 бар.

- Заканчивать: Мы шлифуем и покрываем УФ-защитой

- Тест: Мы проверяем каждую часть на настоящем R6

Это делает наши детали лучше чем те, кто пропускает шаги, чтобы сэкономить деньги.

Реальные проблемы райдеров, которые мы решаем

Проблема #1: Трещины в пластиковых деталях

Пластиковые вентиляционные отверстия трескаются при столкновениях или даже от ударов по дороге. Наше углеродное волокно в 5 раз сильнее чем пластик.

Проблема #2: Мотоцикл перегревается

Стандартные вентиляционные отверстия не пропускают достаточно воздуха. Ваш мотоцикл становится слишком горячим. Наши вентиляционные отверстия имеют форму, позволяющую втягивать воздух больше воздуха для охлаждения двигателя.

Проблема #3: Скучный вид

Все стоковые R6 выглядят одинаково. С нашими изготовленное на заказ углеродное волокно детали, ваш мотоцикл будет выделяться на каждой байк-встрече.

Проблема #4: Тяжелые детали

Стандартные детали тяжелые. Наши детали из углеродного волокна могут сэкономить до 60% веса. Это помогает вашему байку лучше управляться.

Легко купить и установить

Покупка - это простой:

- Выберите год выпуска R6

- Выберите свой карбоновый стиль

- Выберите матовый или глянцевый

- Добавить в корзину

- Получите быструю доставку

Установка - это легкий:

- Снимите старые вентиляционные отверстия (всего несколько болтов)

- Чистая монтажная зона

- Установите новые карбоновые вентиляционные отверстия

- Затяните болты.

- Похвастайтесь перед друзьями!

Никаких специальных инструментов не требуется. Если вы умеете пользоваться гаечным ключом, вы сможете это сделать!

Диапазон цен, соответствующий вашему бюджету

У нас есть варианты на любой кошелек:

- Базовый: $143-$200 для стандартных карбоновых воздухозаборников

- Премиум: $200-$300 для автоклавного отверждения со специальными переплетениями

- Обычай: $300+ для цветного углерода и специальных заказов

Все цены включают нашу гарантию соответствия. Если что-то не подходит идеально, мы заменим его бесплатно.

Что говорят другие гонщики

«Быстрая доставка! Деталь подошла идеально и выглядела великолепно». – Билл С., Северная Каролина

«Мой R6 теперь работает холоднее и привлекает больше внимания». – Майк Т., Калифорния

«Эти вентиляционные отверстия спасли мой двигатель в жару во время гоночного дня». – Сара К., Техас

Вопросы, которые нам задают водители

Подойдут ли они к моему велосипеду?

Да! Мы делаем детали для каждого модельного года R6 с 2003 по настоящее время. Каждая деталь сделана для вашего мотоцикла.

Подходят ли они для использования на треке?

Да! Наши детали сделаны как для дорог, так и для трека. Для моделей 2017+ у нас есть специальные впускные трубы только для трека.

Сколько времени занимает доставка?

Товары со склада в США отправляются в течение 24 часов. Индивидуальные заказы выполняются около 6 недель.

Будет ли углеродное волокно действительно иметь значение?

Да! Помимо отличного внешнего вида, детали из углеродного волокна снижают вес, улучшают охлаждение и добавляют прочности.

Почему стоит выбрать нас для удовлетворения ваших потребностей в углеродном волокне?

Мы не просто продавцы. Мы углеродное волокно эксперты. Мы производим все наши детали на собственном заводе. Это означает:

- Лучший контроль качества

- Индивидуальные опции, которые другие не могут предложить

- Прямое ценообразование (без посредников)

- Экспертная поддержка от реальных производителей

Приобретите карбоновые воздухозаборники для Yamaha R6 уже сегодня

Не стоит больше ездить со скучными, тяжелыми и горячими вентиляционными отверстиями. Перейдите на премиальное углеродное волокно Вентиляционные отверстия и почувствуйте разницу!

Заказать сейчас и присоединяйтесь к тысячам счастливых байкеров R6, оснастив свои мотоциклы лучшими деталями из углеродного волокна.

Нажмите здесь, чтобы увидеть все наши воздухозаборники Yamaha R6 Carbon Fiber