Сделайте свой велосипед крутым и быстрым с помощью углеродного волокна!

Ваш Априлия Туоно Выглядит немного простовато? Вы хотите, чтобы это было сильнее и легче? Многие владельцы велосипедов чувствуют себя так. Поцарапанная или поврежденная рама велосипеда — это большая проблема. Она выглядит плохо и может дорого обойтись в ремонте. Мы покажем вам, как углеродное волокно может помочь!

Проблема: Рамы велосипедов царапаются и ломаются

Кататься на велосипеде весело! Но раму легко повредить. Камни могут ударить по нему. Вы можете упасть. Даже парковка может привести к царапинам. Это не мелкие проблемы.

- Царапины заставьте свой велосипед выглядеть старым.

- Трещины может сделать ваш велосипед небезопасным.

- Фиксация металлический каркас жесткий и может стоить больших денег.

Это большая проблема для Априлия Туоно владельцы. Вы любите свой велосипед. Вы хотите, чтобы он выглядел великолепно и был безопасным для езды, поэтому вам нужно поддерживать его в отличной форме.

Агитация: проблемы ухудшаются!

Подумайте об этих проблемах еще раз:

- А поцарапанная рама затрудняет продажу вашего велосипеда. Люди не будут платить за него столько.

- А сломанная рама может привести к аварии. Это очень опасно!

- Обычный металлические рамы тяжелые. Это делает ваш велосипед медленнее.

- Ржавчина может случиться на металле. Углеродное волокно не ржавеет.

| Проблема | Что происходит? | Насколько все плохо? |

|---|

| Царапины | Велосипед выглядит плохо, ремонт стоит денег | Плохой |

| Трещины | Велосипед небезопасен, его ремонт очень дорогой | Очень плохо |

| Тяжелая рама | Велосипед медленнее | Плохой |

| Ржавчина | Рама слабеет, выглядит ужасно | Очень плохо |

Эти проблемы просто так не уходят. Они становятся худший со временем. Не ждите, пока станет слишком поздно!

Решение: чехлы и защитные накладки на раму из углеродного волокна!

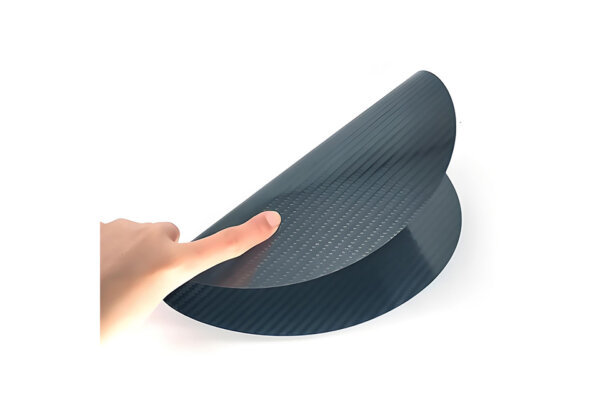

Углеродное волокно вот ответ! Это сильный, свет, и выглядит удивительный. Мы делаем обычай детали из углеродного волокна для вашего Априлия Туоно.

Вот почему углеродное волокно здорово:

- Супер сильный: защищает ваш велосипед от камней, падений и царапин.

- Суперлегкий: Это делает ваш велосипед более быстрым и легким в управлении.

- Выглядит круто: Это дает вашему велосипеду гоночный стиль смотреть.

- Нет ржавчины: Углеродное волокно не ржавеет как металл.

- Индивидуальная подгонка: Сделано специально для вашего велосипеда, многие Априлия Туоно модели, все модельные годы.

Каркас из углеродного волокна охватывает пройдитесь по раме вашего велосипеда. Защитные кожухи из углеродного волокна защита мелких деталей. И то, и другое обеспечивает безопасность и привлекательный внешний вид вашего мотоцикла.

Мы производим лучшее углеродное волокно!

Мы углеродное волокно эксперты! Мы делаем детали для многих велосипедов, таких как Aprilia Tuono V4 1100 Завод, и старые велосипеды, такие как Туоно 1000 (2004-2010). Мы даже делаем детали для новых велосипедов, таких как Туоно 660 (2025+).

Мы предлагаем:

- Изготовленное на заказ углеродное волокно: Мы можем изготовить любую необходимую вам деталь.

- OEM/ODM-сервис:Мы можем подобрать детали, которые были в комплекте с вашим велосипедом.

- Высокое качество материалы.

Мы можем изготовить детали в разных стилях:

Наши детали имеют особое защищен от УФ-излучения покрытие. Это позволяет им выглядеть новыми в течение длительного времени[^6]. Это то же самое покрытие, которое используется на Детали Ducati OEM из углеродного волокна.

Взгляните на эту диаграмму!

| Бренд | Подходит для этих велосипедов | Из чего это сделано | Сколько это стоит | Рейтинг пользователей | Лучшее в этом |

|---|

| Carbon2race | 2004-2024 (Туоно 1000/В4Р/660) | 245 г/м² твил (типа Aprilia) | Позвоните, чтобы узнать цену | 4.6/5 | Сделано вручную, прочное, УФ-покрытие |

| RPM-углерод | 2021+ (Tuono 660/V4 1100) | Кованые или саржевые | Позвоните, чтобы узнать цену | 4.8/5 | Множество стилей, подходит для новых велосипедов |

| Ильмбергер | Tuono V4 1100 Заводской (2021+) | Препрег (производство Германии) | Позвоните, чтобы узнать цену | Нет рейтинга | Идеально подходит, легко надевать |

Мы производим детали, которые так же хороши, или лучше, чем эти! И мы можем сделать их только для тебя!

Какие детали мы можем изготовить?

Мы можем сделать практически любой деталь для вашей Aprilia Tuono:

- Переднее крыло

- Чехлы на задний хаггер/задний маятник

- Крышки двигателя (Крышка сцепления, Крышка генератора)

- Боковые панели бака

- Крышка цепи

- Крышки рам

- Защита радиатора

- Крышка воздушного короба

- Чехол на сиденье

- Крышки впускных отверстий

- Защита вилки

- Крышки баков

Все наши детали сделаны из 100% углеродное волокно. Они будут защитите свой велосипед, сохраняя его в спецификации производителя оригинального оборудования.

Ключевые слова LSI (слова, которые означают одно и то же)

Мы используем все нужные слова, чтобы люди могли найти нас в сети! Вот некоторые из них:

- Детали Aprilia Tuono из углеродного волокна

- Крышки рам

- Модель V4 1100RR

- Передний брызговик

- Защита двигателя

- Предварительно пропитанное углеродное волокно

- Легкая технология

- OEM-спецификации углеродного волокна

- Модернизация внешнего вида мотоцикла

Сущности (Важные вещи)

- Aprilia Tuono V4 1100 Завод

- Carbon2race

- RPM-углерод

- Переднее крыло

- Крышка сцепления

- Предварительно пропитанное углеродное волокно

- OEM-адаптируемость

- Культура модификации мотоцикла

Мы лучше остальных!

Другие компании производят детали из углеродного волокна. Но мы разные!

- Мы предлагаем индивидуальная работа. Мы можем сделать что-либо вам нужно.

- Мы предлагаем OEM/ODM. Мы можем изготовить детали, которые выглядят точно как в оригинале.

- Мы используем специальные высокая температура, высокое давление способы сделать наш углеродное волокно. Это делает его очень сильный.

- Наш мастера очень хороши в своей работе. Они следят за тем, чтобы каждая часть была идеальный.

- Мы можем сделать специальные конструкции, нравиться индивидуальные переплетения.

- У нас есть быстрая доставка.

Хотите особый цвет? Мы можем это сделать! Хотите особый дизайн? Мы можем это сделать! Узнайте больше о наших индивидуальных работах с углеродным волокном.

Как установить детали из углеродного волокна

Легко поставить наш детали из углеродного волокна на велосипеде!

- Чистый рамка с алкоголем.

- Положите часть из углеродного волокна на месте.

- Использовать Двусторонний скотч 3М чтобы приклеить его. (Вы также можете использовать силиконовый клей, чтобы сделать его более прочным.)

Важный: Делайте это в теплом месте. Клей работает лучше, когда тепло.

Как ухаживать за углеродным волокном

Углеродное волокно прост в уходе:

FAQ (вопросы, которые задают люди)

В: Углеродное волокно сделает мой велосипед теплее?

A: Нет! Наши детали имеют воздушные зазоры, чтобы ваш мотоцикл оставался прохладным.

В: Могу ли я воспользоваться гарантией на свой велосипед?

A: Наши детали сделаны так, чтобы идеально подойти вашему велосипеду. Они не должны вызывать никаких проблем с вашей гарантией.

В: Какое покрытие выбрать: матовое или глянцевое?

А: Матовый лучше, если вы не хотите чистить его все время. Глянцевый отлично смотрится на выставочных мотоциклах.

Вывод: приобретите углеродное волокно сегодня!

Углеродное волокно это лучший способ защищать твой Априлия Туоно и сделать так, чтобы это выглядело удивительный. Мы лучшие. углеродное волокно производитель. Мы можем сделать любая часть вам нужно, в любом случае Вы хотите этого. Ваш повреждение рамы это проблема, которую мы можем решить. С нашими углеродное волокно мы решим проблему. Не ждите, и не позволяйте проблемам усугубляться. Получите защита и производительность, получите наш детали из углеродного волокна на заказ сегодня!