Заставьте свой Rolls-Royce сиять: лучшее Углеродное волокно Комплекты обвесов!

Вы любите свой Rolls-Royce? Это очень хорошая машина. Но хотите ли вы сделать ее еще лучше? Хотите ли вы, чтобы она была легче, Быстрее, и посмотрите супер круто? Мы можем помочь!

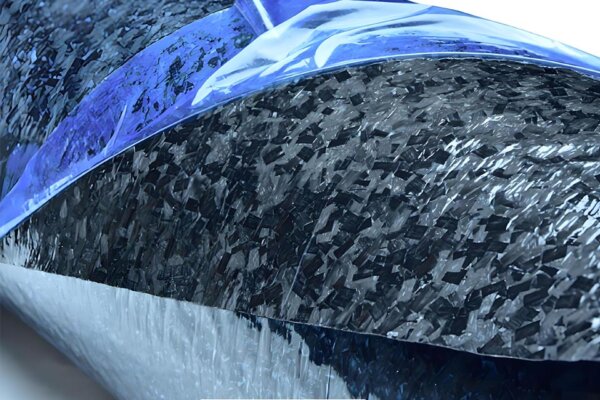

Мы делаем углеродное волокно запчасти для автомобилей. Углеродное волокно очень сильный и очень свет. Это похоже на волшебство! Мы можем изготовить специальные детали специально для вашего Роллс-Ройс. Эти части называются обвесы.

Проблема: Ваш Rolls-Royce хорош, но он может быть и ВЕЛИКОЛЕПНЫМ!

Ваш Rolls-Royce — очень хорошая машина. Она большая и сильная. Но, большая и сильная может также означать тяжелый. А тяжелый Машина не такая быстрая. тяжелый автомобиль расходует больше бензина.

- Тяжелый автомобиль = помедленнее машина.

- Тяжелый машина = больше денег на бензин.

Некоторый обвесы для машин нехороши. Они сделаны из дешёвых вещей. Эти вещи могут сломаться. Они также могут сделать так, чтобы ваша машина выглядела плохо.

| Плохие вещи | Проблема |

|---|

| Стекловолокно | Может легко треснуть |

| Дешевый пластик | Может выгореть на солнце |

| Мокрое углеродное волокно | Не такой сильный, может пожелтеть |

Некоторый обвесы не подходят правильно. Это может вызвать большие проблемы. датчики на вашем автомобиле может не работать. Эти датчики помочь вам припарковаться. Они помогают вам оставаться в безопасности.

Агитировать: Не позволяйте плохому обвесу навредить вашему автомобилю!

Представьте себе: вы покупаете обвес. Вы очень счастливы. Но это не подходит. датчики не работают. Ваш прекрасный Rolls-Royce теперь проблема!

Или вы покупаете обвес Сделано из дешёвого материала. Сначала выглядит хорошо. Но потом начинает трескаться. Начинает выцветать. Твоя машина выглядит старой и грустной.

Это нехорошо! Вы потратили кучу денег. Теперь вам придется потратить еще больше, чтобы это исправить.

Плохие вещи, которые могут произойти:

- Комплект обвеса не подходит.

- Датчики не работают.

- Комплект обвеса трескается или выцветает.

- Вы тратите деньги впустую!

Некоторые люди продают обвесы которые не являются реальными углеродное волокно. Они говорят, что это углеродное волокно. Но это не так. Это трюк! Они используют мокрое углеродное волокно. Влажный углеродное волокно может стать слабым. Мокрое углеродное волокно может помочь вам сбросить всего около 18 кг, что равнозначно 4 большим мешкам песка из вашего багажника.

Решение: Наш Углеродное волокно Комплекты обвеса сделают ваш автомобиль УДИВИТЕЛЬНЫМ!

Мы разные! Мы делаем лучшее углеродное волокно обвесы. Мы используем сухое углеродное волокно. Сухое углеродное волокно это лучший. Это очень, очень сильный. Это также очень, очень свет.

Сухое углеродное волокно сделает ваш автомобиль намного легче, потеряв до 50 кг. Это как 11 больших мешков песка!

Почему наши обвесы лучшие:

- Супер сильный: Наш сухое углеродное волокно как супергерой!

- Суперлегкий: Ваша машина будет намного Быстрее.

- Идеальная посадка: Наш Комплекты кузова для вашего Rolls-Royce в самый раз.

- Выглядит отлично: Ваша машина будет выглядеть на миллион долларов!

Мы можем сделать обычай части для вашего автомобиля. Это значит, что мы делаем детали только для вас! Ни у кого больше не будет таких же деталей. Ваш автомобиль будет единственным в своем роде!

Мы также можем изготавливать детали, которые выглядят как детали от производителя автомобилей. Это называется OEM. Выглядит так, будто он был в комплекте с машиной. Он идеален!

Мы также можем изготовить детали любым способом, который вы хотите. Это называется ОДМ. Вы говорите нам, что вы хотите. Мы делаем это!

Что мы можем сделать для вашего Rolls-Royce:

Наше углеродное волокно лучшее, потому что:

- Мы используем лучший материалы.

- Мы используем лучший машины.

- У нас есть лучший Работники. Они очень хорошо справляются со своей работой!

Еще больше преимуществ нашего углеродного волокна!

Наш углеродное волокно Детали не просто хорошо выглядят. Они делают вашу машину лучше!

- Лучший поток воздуха: Наш обвесы помочь воздуху двигаться вокруг вашего автомобиля. Это заставляет ваш автомобиль двигаться Быстрее! Это называется аэродинамика.

- Безопаснее: Наш углеродное волокно очень сильный. Это может помочь защитить вас в случае аварии.

- Длится дольше: Наш углеродное волокно Не выцветает на солнце. Не трескается легко. Прослужит долго! Имеет специальное покрытие, которое не дает солнцу повредить его.

Давайте поговорим о моделях Rolls-Royce!

Мы делаем углеродное волокно детали для многих автомобилей Rolls-Royce:

- Роллс-Ройс Врайт: У нас есть Комплекты полного обвеса M Style из углеродного волокна. Они делают ваш Wraith очень крутым. Они также заставляют его двигаться Быстрее!

- Роллс-Ройс Куллинан: У нас есть конверсионные комплекты кузова из сухого карбона. Они сделают ваш Cullinan похожим на новую модель 2025 года! У нас также есть Широкие обвесы Phoenyx Design. В этих комплектах используется 100% сухое углеродное волокно.

- Роллс-Ройс Призрак: У нас есть Комплекты кузова из углеродного волокна в стиле M. Они делают ваш Ghost очень гладким. Они также делают его более аэродинамический.

Мы упрощаем процесс приобретения автомобиля вашей мечты!

Мы знаем, что покупка обвес может быть сложно. Мы делаем это легко!

- Расскажите нам, что вы хотите: Вы хотите обычай дизайн? Вы хотите, чтобы он выглядел как OEM части? Расскажите нам!

- Мы составляем план: Мы покажем вам, как будет выглядеть ваш автомобиль.

- Мы изготавливаем ваши детали: Мы используем лучшее углеродное волокно. Мы используем лучший машины.

- Мы отправляем его вам: Мы можем отправить наш обвесы по всему миру.

Мы также даем вам гарантия. Это значит, что если что-то пойдет не так, мы это исправим! Некоторые компании, например Renegade Design, дают 5-летнюю гарантию гарантия.

Реальные цифры: почувствуйте разницу!

| Особенность | Обычная автомобильная деталь | Наша деталь из углеродного волокна |

|---|

| Масса | Тяжелый | Очень легкий |

| Сила | Хороший | Супер сильный |

| Смотреть | Хорошо | Удивительный! |

| Цена | дешевый | стоило того! |

Что говорят люди

Люди любят наш углеродное волокно части! Они говорят:

- «Моя машина такая Быстрее сейчас!"

- «Это выглядит так прохладный!”

- «The качество потрясающе!»

Ключевые слова, которые мы использовали очень часто!

Мы производим:

- Высококачественное углеродное волокно.

- Бамперы из углеродного волокна.

- Капоты из углеродного волокна.

Мы работаем со следующими автомобилями:

- Роллс-Ройс Врайт.

- Роллс-Ройс Cullinan

- Роллс-Ройс Призрак.

Наши детали:

- Легкие материалы из углеродного волокна.

- Индивидуальный дизайн бампера.

- Комплекты для улучшения аэродинамики.

Мы изготавливаем все виды деталей, такие как:

- Капоты двигателя полностью из углеродного волокна.

- Передний и задний спойлеры.

- Боковые юбки

- Диффузоры из углеродного волокна

Наши проекты:

- OEM стиль

- Обычай стиль

- Широкие обвесы

Готовы сделать свой Rolls-Royce УДИВИТЕЛЬНЫМ?

Не ждите! Сделайте свой Rolls-Royce лучший это может быть. Нажмите здесь, чтобы увидеть наши потрясающие обвесы из углеродного волокна! Или, посмотрите другие потрясающие детали для автомобиля из углеродного волокна!. Хотите чего-то действительно особенного? Посмотрите на наши индивидуальные варианты из углеродного волокна!

Мы есть лучший при создании углеродное волокно части. Позвольте нам помочь вам воплотить ваши мечты об автомобиле в реальность! Мы предлагаем обычай, OEM/ODM обслуживание изделий из углеродного волокна.