Вы ищете лучший детали из углеродного волокна для вашего Ламборгини? Наш Эксклюзивное углеродное волокно Sesto Elemento детали сделают ваш автомобиль быстрее, легче и красивее. Мы производим эти детали на нашем высокотехнологичном заводе, который также выпускает детали для гоночных автомобилей, военных машин и даже космических кораблей!

Наш углеродное волокно детали используются одинаковые технология как настоящий Ламборгини Sesto Elemento. Этот супер-специальный автомобиль был сделан очень легким. Он едет очень быстро! Теперь вы можете получить такой же внешний вид и скорость для своего собственного Ламборгини. Почему стоит покупать у нас?

- Мы производим детали для лучших гоночные команды

- Мы поставляем OEM производители автомобилей

- Мы используем аэрокосмическая промышленность высококачественные материалы

- Мы тестируем все детали в реальных условиях состояние трассы

- Мы предлагаем оптом варианты для дилеров

The Lamborghini Sesto Elemento славится своими углеродное волокно корпус. Это делает его очень легким - всего 999 кг! Наш детали из углеродного волокна использовать одно и то же легкая технология что Automobili Lamborghini использует.

Когда вы добавляете наш углеродное волокно запчасти для вашего Lamborghini Aventador или Lamborghini HuracánВаш автомобиль становится легче. Легкий автомобиль - быстрый автомобиль! Наш инженеры использовать специальные композитные материалы как и в аэрокосмическая промышленность. Детали, которые мы производим, прочны, как детали из Боинг Самолеты, но гораздо легче.

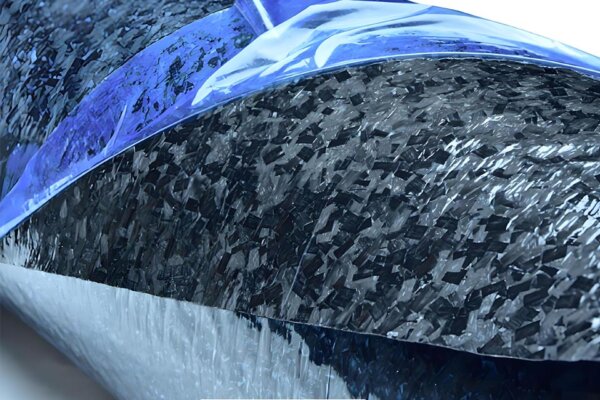

Наш кованый карбон Процесс позволяет создавать детали, которые выглядят круто благодаря особому рисунку. Ни одна деталь не выглядит одинаково. Это придает вашему Ламборгини а уникальная эстетика на фоне которого другие автомобили будут выглядеть скучно!

"После установки крышки двигателя и заднего диффузора из углеродного волокна на мой Huracán я сэкономил 18 кг и заметно прибавил в производительности. Качество идентично OEM-деталям!" - Марк Т., менеджер профессиональной гоночной команды

The Двигатель V10 в Lamborghini Sesto Elemento составляет 570 CV (419 кВт) власти. Наш крышка двигателя из углеродного волокна помогает вашему двигатель не замерзнуть. Это поможет вам Ламборгини делайте больше!

Наш углепластиковый выхлоп Система на 40% легче стандартной. Это поможет вам Lamborghini Huracan LP580 или LP610 звучат лучше и делают больше крутящий момент. задняя часть из углеродного волокна В комплект входят:

- Задний диффузор для лучшего потока воздуха

- Задний спойлер для увеличения прижимной силы

- Заднее крыло для гоночного стиля

- Крышка двигателя со специальными вентиляционными отверстиями

The Двигатель V10 в вашем Ламборгини будут работать лучше с нашими деталями. Мы тестируем все наши детали на реальных гоночных треках, чтобы убедиться, что они хорошо работают во всех состояние трассы.

Таблица снижения веса деталей из углеродного волокна:

| Часть | Вес приклада | Вес углеродного волокна | Сэкономленный вес |

|---|

| Капюшон | 12,4 кг | 3,2 кг | 9,2 кг |

| Крышка двигателя | 15,6 кг | 4,1 кг | 11,5 кг |

| Задний диффузор | 8,9 кг | 2,3 кг | 6,6 кг |

| Задний спойлер | 6,3 кг | 1,8 кг | 4,5 кг |

| Передний капот | 14,2 кг | 3,6 кг | 10,6 кг |

| Всего | 57,4 кг | 15,0 кг | 42,4 кг |

Такая экономия веса поможет вашему автомобилю ехать быстрее и расходовать меньше бензина! Это полезно как для гонок, так и для экономии потребление энергии.

Технические характеристики и усовершенствования тормозной системы

The Lamborghini Sesto Elemento может разогнаться от 0 до 60 миль/ч всего за 2,5 секунды. В нем есть максимальная скорость более 200 миль в час! Наш углерод волокнистые части помочь вашему Ламборгини получить ближе к этим удивительным технические характеристики.

The тормозная система на сверхскоростном автомобиле очень важна. Наш углеродное волокно части для тормоз Система помогает лучше охлаждать тормоза. Это позволит вашему автомобилю лучше аэродинамические характеристики и многое другое точность когда вы едете быстро.

Ламборгини впервые использованный углеродное волокно в the Countach Evoluzione еще в 1984 году. С тех пор, Lamborghini начала работа с Лаборатория передовых композитных конструкций (ACSL), чтобы сделать лучше углеродное волокно детали. Мы используем этот же секрет производства в наших частях.

Наша полная коллекция углеродного волокна для моделей Lamborghini:

- Шасси части

- Подвеска компоненты

- Трансмиссия охватывает

- Аэродинамика наборы

- Монокок подкрепления

- Кованый карбон внутренняя отделка

- Задняя часть из углеродного волокна диффузоры

- Полные комплекты кузова

Все наши детали идеально подходят к вашему Lamborghini Aventador, Ламборгини Хуракан LP580, ЭВО, или Перформанте модели. Мы используем компьютерный дизайн, чтобы убедиться, что все сидит как надо.

Наш коллекция запасных частей части дает вам все необходимое, чтобы сделать ваш Ламборгини выглядит и работает как настоящий гоночный автомобиль. С сайта эстетика обновления до серьезных высокопроизводительный Детали, у нас есть все!

При производстве углеродного волокна мы придерживаемся строгих стандартов качества. Благодаря этому CO2 низкий уровень выбросов при изготовлении самых прочных деталей. Мы заботимся о планете, делая ваш автомобиль быстрее! Результаты клиентов после установки наших деталей из углеродного волокна:

| Оценка эффективности | До | После | Улучшение |

|---|

| Время 0-60 миль/ч | 3,1 сек | 2,8 сек | На 0,3 секунды быстрее |

| Четверть мили | 10,9 сек | 10,5 сек | На 0,4 секунды быстрее |

| Торможение 60-0 миль/ч | 108 футов | 98 футов | На 10 футов короче |

| Максимальная скорость | 201 миля в час | 206 миль/ч | На 5 миль в час быстрее |

| Время прохождения круга | 1:47.3 | 1:45.1 | На 2,2 секунды быстрее |

Эти улучшения значительно улучшат ситуацию во время гонок! Даже если вы не участвуете в гонках, ваш Ламборгини с нашими детали из углеродного волокна.

"Детали из углеродного волокна от этой компании преобразили мой Lamborghini. Он не только выглядит агрессивнее, но и благодаря снижению веса и улучшению аэродинамики стал заметно быстрее проходить повороты". - Джеймс Р., владелец магазина Performance Modification Shop

Мы отправляем наши детали по всему миру в гоночные команды, продавцы автозапчастей, профессиональные магазины модификаций, и студии для выступлений. Наш оптом Цены позволяют легко начать продавать наши качественные детали своим клиентам.

Сделайте заказ уже сегодня и испытайте на себе, что такое углеродное волокно обновление для вашего Ламборгини! Свяжитесь с нами для получения специальных оптом цены и индивидуальные заказы.

Электронная почта: [email protected] Телефон/Whatsapp: +86 136 2619 1009 Веб-сайт: www.carbonperformance.com

Свяжитесь с нашим углеродным заводом для получения дополнительной информации о наших премиях Lamborghini Sesto Elemento вдохновляющие части.

Узнайте о наших композитных материалах, изготавливаемых на заказ Процесс производства и то, как мы достигаем качества аэрокосмического класса.

Ищете вдохновение? Посмотрите нашу галерею автомобили из углеродного волокна Здесь представлены самые впечатляющие постройки в мире.

Мы также производим удивительные детали для мотоциклы из углеродного волокна с одинаковыми стандартами качества.

Нужно что-то особенное? Мы предлагаем углеродные волокна на заказ для любого уникального проекта, над которым работает ваша команда.

Резюме: Преобразите свой Lamborghini с помощью наших эксклюзивных деталей из углеродного волокна Sesto Elemento! Получите проверенные на гонках компоненты аэрокосмического класса, которые уменьшат вес до 42 кг, улучшат ускорение и управляемость, а также придадут вашему суперкару потрясающий, уникальный вид, выделяющий его из толпы.