Придайте своему Rolls Royce Cullinan потрясающий вид с помощью углеродного волокна!

Вы хотите, чтобы ваш Роллс-Ройс Куллинан смотреть супер круто? Вы хотите, чтобы это было легче и Быстрее? Многие люди чувствуют то же самое. Они хотят, чтобы их внедорожник класса люкс быть лучший это может быть. Это проблема для некоторых. Роллс-Ройс Cullinan уже здорово. Но это может быть даже лучше!

Давайте поговорим о том, как это сделать.

The Проблема: Ваш Куллинан может быть даже Более Потрясающий

The Роллс-Ройс Куллинан это очень хорошо машина. Это большой и сильный. Это также очень причудливый. Но некоторые люди хотят более.

- Они хотят уникальный смотреть.

- Они хотят лучшая производительность.

- Они хотят, чтобы их машина выделялась.

The обычный Куллинан хорош. Но это не идеальный для всех. Некоторые части сделаны из пластик или металл. Эти части могут быть тяжелый.

| Часть | Оригинальный материал | Проблема |

|---|

| Передний бампер | Пластик/Металл | Может быть тяжелым, выглядит обычно |

| Задний бампер | Пластик/Металл | Может быть тяжелым, выглядит обычно |

| Капот двигателя | Металл | Тяжелый, менее стильный |

Именно здесь мы можем помочь сделать ситуацию лучше.

Агитировать Проблема: Тяжелые детали и обычный вид

Подумайте об этом. Ваш Роллс-Ройс Куллинан это особенный машина. Но у многих других людей такая же машина. Они все выглядят почти одинаковые. Вы хотите, чтобы ваша машина была похожа на все остальные? Нет!

Тяжелые детали делают ваш автомобиль помедленнее. Они также заставляют его использовать больше газа. Это нехорошо. А стильный Капот из углеродного волокна не только для красоты. Он может помощь машина поехала лучше.

Тяжелые детали может замедлить ваш автомобиль. Базовые бамперы не добавляйте к внедорожник класса люксвзгляд.

Вот некоторые проблемы с запас части:

- Масса: Тяжелый детали делают машину помедленнее.

- Выглядит: Обычный части выглядят скучный.

- Производительность: Тяжелый части могут сделать машину управляемой худший.

The Решение: Углеродное волокно!

Мы делаем углеродное волокно части. Углеродное волокно является удивительный!

- Это очень легкий.

- Это очень сильный.

- Это выглядит очень круто.

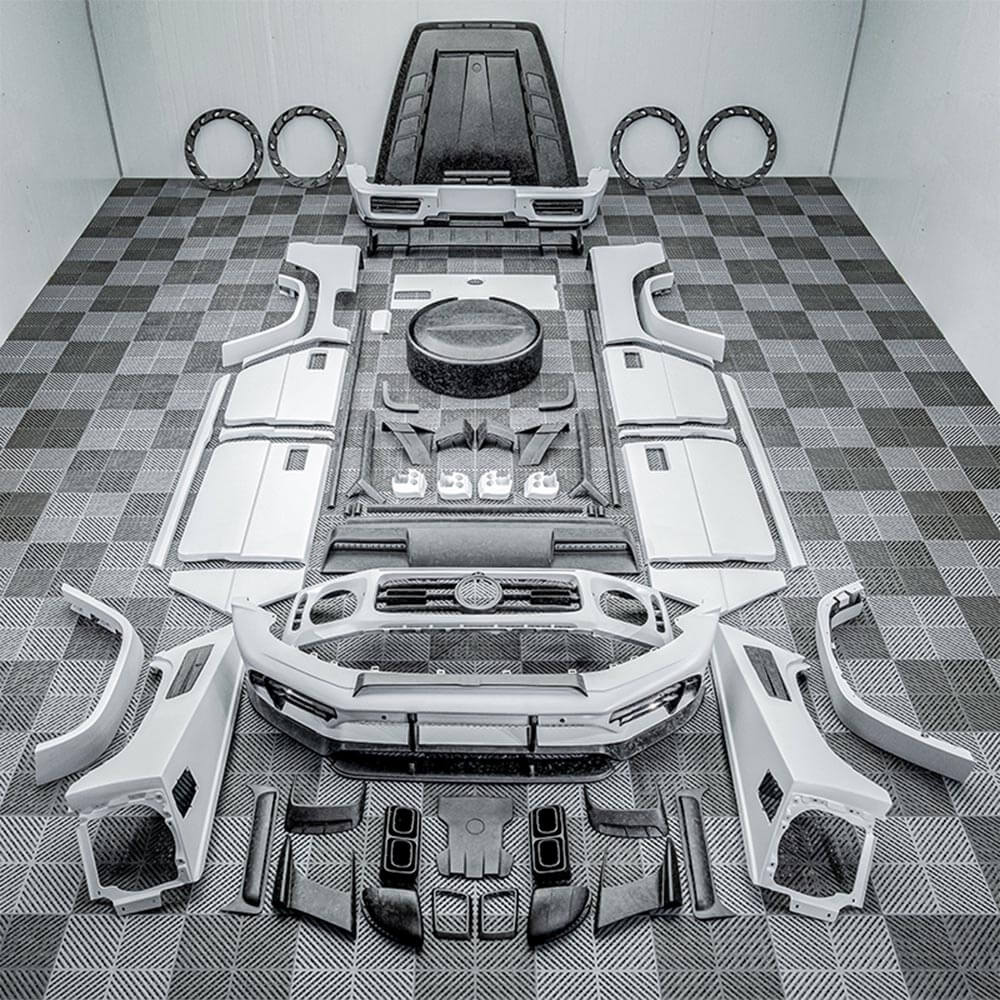

Мы можем сделать обычай части для вашего Роллс-Ройс Куллинан. Мы можем сделать:

- Передние бамперы из углеродного волокна

- Задние бамперы из углеродного волокна

- Капоты из углеродного волокна

- И более!

Мы предлагаем OEM/ODM-сервис. Это означает, что мы можем изготавливать детали, которые подходят отлично. Мы также можем изготовить детали, которые уникальный к вам. Мы являемся производитель углеродного волокна. Мы знаем углеродное волокно!

Наши сильные стороны:

- Индивидуальный дизайн: Мы делаем то, что ты хотеть.

- Качество OEM: Детали, которые подходят как оригинальный.

- Сильный и легкий: Лучше, чем пластик или металл.

- Быстрое обслуживание: Мы работаем быстро.

- Производство препрегов: Использование литья под высоким давлением обеспечивает экологическую долговечность.

Какие детали мы можем изготовить?

Мы можем сделать много углеродное волокно части для вашего Cullinan. Вот некоторые примеры:

1. Бамперы из углеродного волокна

The передний бампер это лицо вашего автомобиля. А передний бампер из углеродного волокна делает ваш автомобиль похожим спортивный и агрессивный. Это также делает машину легче. А задний бампер из углеродного волокна завершит заднюю часть вашего автомобиля.

- Мансори делает прохладный Передний бампер. Он имеет большие воздухозаборники. Это помогает двигателю получить больше воздуха.

- Форца делает сухой углерод бампер. Он подходит отлично.

- А передний спойлер можно добавить.

2. Капот из углеродного волокна

The капот двигателя это большой часть автомобиля. А капот из углеродного волокна экономит много веса.

- А капот из углеродного волокна может быть на 18 кг легче чем металлический капот.

- Углеродная промышленность делает хороший капюшон.

- А капот из углеродного волокна является стильный.

3. Другие детали из углеродного волокна

Мы также можем изготовить:

- Боковые юбки: Они придают автомобилю вид ниже.

- Щитки колесных арок: Они добавляют спортивный трогать.

- Задний диффузор: Это помогает с расход воздуха.

- Зеркала из углеродного волокна: Добавьте дополнительный штрих к образу.

- Крылья из углеродного волокна

- Разделители из углеродного волокна

А Конверсия сухого углерода будет потрясающе. Машина получит аэродинамические улучшения. Это будет выглядеть так, как будто у него есть широкий обвес.

Какую пользу приносит углеродное волокно?

Давайте посмотрим на некоторые числа:

| Выгода | Деталь | Источник |

|---|

| Снижение веса | Капот из углеродного волокна может быть легче на 18 кг. | |

| Улучшенная управляемость | Меньший вес означает лучшую управляемость. | |

| Лучшее ускорение | Меньший вес означает более быстрое ускорение. | |

| Круче выглядит | Углеродное волокно выглядит спортивно и современно. |

А как насчет других компаний?

Есть и другие компании, которые делают углеродное волокно части.

- Мансори это большой компания. Они делают очень причудливый части. Их части очень дорого.

- Форца делает хорошие детали. Они не такие дорогой как Мэнсори.

- Некоторые компании в Азия делать дешевле части. Но качество может быть не так уж и хорош.

Мы другой. Мы предлагаем:

- Обычай конструкции.

- OEM/ODM услуга.

- Хорошие цены.

- А решетка из углеродного волокна также можно сделать.

Мы используем предварительно пропитанное углеродное волокно. Это лучший добрый. Это сильный и свет.

С нашим изготовленное на заказ углеродное волокно, вы можете дать вашему внедорожнику визуальное снижение. Он будет иметь дизайн в стиле космического корабля. Он будет иметь роскошное исполнение.

Что ты хочешь?

Подумайте о том, чего вы хотите для своего Роллс-Ройс Куллинан.

- Вы хотите полный комплект кузова?

- Вы хотите просто немного части?

- Вы хотите обычай дизайн?

Мы можем помочь вам со всем этим. Мы эксперты в изготовленное на заказ углеродное волокно. Мы одни из лучших престижные тюнинговые брендыМы знаем все о роскошный стиль внедорожника.

Заставить машину иметь оптическая настройка требует мастерства. Мы делаем карбон ручной работы предметы. Вы получите лучшие роскошные аксессуары для внедорожников. Ваш автомобиль будет иметь акценты из углеродного волокна.

Начиная

Это легкий для начала.

- Связаться с нами. Расскажите нам, чего вы хотите.

- Мы дадим вам цитировать.

- Мы сделаем ваш углеродное волокно части.

- Вы можете иметь их установлен. Профессиональная установка это обязательно.

- Вы можете получить замена бамперов.

Затем вы можете наслаждаться своим удивительный Роллс-Ройс Куллинан! Мы делаем производство препрегов. Это дает части устойчивость к воздействию окружающей среды. Мы также предлагаем роскошные обновления интерьера.

Еще больше крутых вещей!

Мы не просто делаем детали для Роллс-Ройс Куллинан. Мы также изготавливаем детали для:

Заключение

Твой Роллс-Ройс Куллинан это большой машина. Но это может быть даже лучше. Углеродное волокно части делают это легче, Быстрее, и кулер.

Мы являемся производитель углеродного волокна. Мы предлагаем обычай, OEM/ODM обслуживание. Мы можем сделать идеальный части для вас.

Свяжитесь с нами сегодня! Давайте сделаем ваш Cullinan удивительный! У вашего автомобиля будет отличный поверхность из углеродного волокна. Он будет иметь глянцевый углерод.