Преобразите свой Lamborghini Huracan с помощью премиального комплекта для кузова из углеродного волокна

Вы готовы сделать свой Ламборгини Хуракан Выделиться из толпы? Наш топ обвес из углеродного волокна изменит внешний вид и работу вашего автомобиля. Созданные для гоночных команд, магазинов автозапчастей и крупных автопроизводителей, наши Ламборгини Huracan из углеродного волокна детали привносят стиль гоночного трека на улицу.

Почему вы выбрали нас? Мы производим детали для гоночных видов спорта, новых автомобилей и даже самолетов! Наша команда знает, как сделать лучшие детали из углеродного волокна которые подходят именно вам. Каждая деталь сделана так, чтобы сделать ваш Lamborghini Huracan LP610 выглядят лучше и едут быстрее.

Закажите сейчас, чтобы получить:

- Детали, которые идеально подходят

- Значительно меньше вес

- Настоящий вид гоночного автомобиля

- Быстрый корабль к вам

Лучшие углепластиковые элементы для Lamborghini Huracan

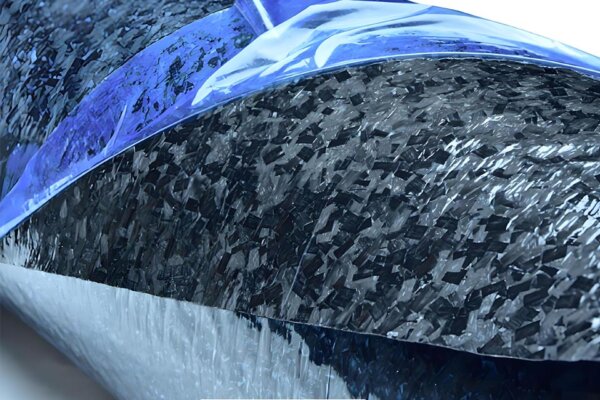

Наш углеродное волокно запчасти для Lamborghini Huracan LP610 изготовлены с той же тщательностью, что и детали для гоночных автомобилей. Мы используем самые лучшие материалы, чтобы ваш автомобиль получал только самое лучшее.

Каждый часть из углеродного волокна создан специально для Ламборгини Хуракан. Они подходят, как будто их привезли из автомагазина. Наш корпус из углеродного волокна детали выглядят великолепно и помогают вашему автомобилю ехать быстро. Мы делаем их для гоночных команд и автосервисов, которые хотят получить самое лучшее. Наш задняя часть из углеродного волокна части и боковые юбки сделать свой Lamborghini Huracan LP610-4 Выглядит некрасиво и помогает ему держаться на дороге.

«The детали из углеродного волокна из этого магазина сделал мой Lamborghini Huracan LP580 выглядят как новый автомобиль. Посадка была точной". - Майк Т., босс гоночной команды

Хотите, чтобы ваш Ламборгини Хуракан чтобы Huracán Performante посмотреть? Наш углеродное волокно детали дадут вам это преимущество. Сайт задний диффузор и спойлер они выглядят великолепно и помогают вашему автомобилю держаться на дороге.

The стиль Задние части из сухого углеродного волокна Мы поможем вашему автомобилю в значительной степени:

- Улучшает поток воздуха

- Помогает прижимать автомобиль к дороге

- Выглядит как гоночная машина

- Снижает вес

Наш стиль performante Комплекты использовались лучшими гоночными командами. Сайт задний спойлер и задний капот двигателя из углеродного волокна работают как настоящие детали гоночных автомобилей. Они не просто для демонстрации - они помогают вашему Lamborghini Huracan LP580 быстрее и лучше поворачивает. Диаграмма соответствия для моделей Lamborghini:

| Часть | Huracan LP610 | Huracan LP580 | Хуракан ЭВО | Tecnica |

|---|

| Капюшон | ✓ | ✓ | ✓ | ✓ |

| Боковые юбки | ✓ | ✓ | ✓ | ✓ |

| Задний диффузор | ✓ | ✓ | ✓ | ✓ |

| Крыло спойлера | ✓ | ✓ | ✓ | ✓ |

Технические характеристики и усовершенствование шасси кузова

The Технические характеристики Lamborghini Huracán показывает, что это отличный автомобиль. Но мы можем сделать его еще лучше с помощью наших Изделия из углеродного волокна. Наши детали работают с автомобильным тормозная система и помочь рулевое управление и подвеска работать лучше.

Технические характеристики наш углеродное волокно комплекты:

- Сделано из кованое углеродное волокно как Sesto Elemento

- Каждая деталь на 40% меньше по весу, чем запасные части

- Проверено в ветровых комнатах для наилучшего аэродинамический поток

- Подходит для автомобиля выхлопная система

The корпус из углеродного волокна детали помогут сделать ваш Ламборгини Huracan LP610 еще больше удовольствия от вождения. Они работают вместе с V10 двигатель и все режимы движения. Детали даже помогают Динамическое рулевое управление Lamborghini работать лучше.

- Лучше максимальная скорость на 5 миль в час

- Более прижимная сила на высоких скоростях

- Меньший вес означает лучшие повороты

- Работает с купе и LP580-2 модели

Наш аэрокосмическая промышленность сорт углеродное волокно Это тот же материал, что используется в гоночных автомобилях. Когда вы модернизируйте свой Lamborghini HuracanВы получаете детали, изготовленные по высочайшее качество с нашего завода, который также производит детали для гоночных автомобилей и самолетов.

The детали из углеродного волокна мы помогаем оптимизировать как воздух движется вокруг вашего автомобиля. Это поможет вам Ламборгини Хуракан В быстрых поворотах лучше держится на дороге. Сайт задний бампер работает с задний капот двигателя из углеродного волокна чтобы сделать поток воздуха плавным. Мы изготовили детали для новый Huracán Модели тоже, например ЭВО и Tecnica. Все наши детали работают с крутящий момент двигателя автомобиля и углерод-керамика тормоза. Что говорят наши клиенты:

- "Мой Lamborghini Huracán выглядит так, как будто она пришла с трассы. Лучшее обвес Я когда-либо использовал его". - Алекс Р., владелец магазина Pro Shop

- The кованые детали из углеродного волокна соответствуют моей машине алькантара Внутри. Идеально стиль." - Команда Veloce Racing

- "Эти ребята знают. автоспорт потребности. Их детали из углеродного волокна помогли нам победить". - Гоночная команда GTR

Почему стоит выбрать наши детали из углеродного волокна?

Когда вы хотите преобразите свой LamborghiniВам нужны детали, изготовленные людьми, которые разбираются в автомобилях. Наша команда имеет корни в автоспорт и работает с Automobili Lamborghini гоночные команды. Наш сайт Запчасти из углеродного волокна для huracan производятся там же, где и детали для гоночных автомобилей и самолетов. Каждый углеродное волокно деталь сделана так, чтобы идеально подходить к вашему Lamborghini Huracan LP610. Процесс заказа:

- Выберите углеродное волокно необходимые детали

- Сообщите нам год и модель вашего автомобиля (LP610, LP580, или ЭВО)

- Мы быстро изготовим или доставим ваши детали

- Легко надеть с помощью справочной документации

- Выглядит хорошо и едет быстро!

Наши детали предназначены для магазинов, гоночных команд и магазинов автозапчастей. Мы можем быстро отправлять большие заказы. Каждый углеродное волокно В комплект входит все, что нужно для его надевания. Вы можете оптимизировать твой Ламборгини Хуракан выглядеть и ускоряться одновременно.

Посмотрите на нашу углеродную фабрику для всех ваших нужд. Узнайте о наших композитных материалах, изготавливаемых на заказ услуги. Вам нужны не только запчасти Lamborghini? Мы также производим автомобили из углеродного волокна компоненты для многих брендов. Ищете варианты с двумя колесами? Посмотрите наш мотоциклы из углеродного волокна коллекция.

Хотите что-то особенное? Мы предлагаем углеродные волокна на заказ для любого проекта. Заказать сейчас и присоединяйтесь к ведущим гоночным командам и магазинам, которые доверяют нашим детали из углеродного волокна сделать свой Ламборгини Хуракан автомобили наилучшим образом.

РЕЗЮМЕ: Повысьте свой Lamborghini Huracan с нашим премиальным углепластиком Комплект кузова - материалы аэрокосмического класса, снижающие вес на 40%, улучшающие аэродинамику и обеспечивающие потрясающий стиль Performante. Идеально подходит для гоночных команд и элитных магазинов, требующих лучших характеристик и внешнего вида.