Where Excellence is Engineered

At Suzhou Scomp Composite, our state-of-the-art manufacturing facility is more than just a building; it’s the heart of our innovation. Every square meter is dedicated to precision, efficiency, and the unwavering pursuit of quality that defines every product we deliver.

A Virtual Tour of Our Facility

قدراتنا التصنيعية

Custom Carbon Fiber Parts, High Volume & Tooling

Curing & Molding: The Heart of Process

This industrial autoclave, at the core of our curing process, utilizes a precision computer-controlled system to maintain exacting parameters throughout the cycle. It achieves temperature uniformity within ±2.5°C and pressure accuracy within ±0.1 bar of the setpoint. This exceptional control ensures every component cures under identical ideal conditions, eliminating voids, perfecting the fiber-resin ratio, and guaranteeing highly repeatable mechanical properties batch-to-batch, forming the foundation for our products’ outstanding reliability and consistency.

CNC Machining & Finishing

Our advanced 5-axis CNC machining centers deliver unparalleled precision for complex carbon fiber components. Utilizing rigid machine construction, high-resolution encoders, and vibration-dampening technology, we consistently hold tolerances within ±0.025mm (±25 microns). This capability, combined with specialized tooling and optimized cutting parameters, allows us to achieve flawless surface finishes and pristine edge quality without delamination or fraying, ensuring perfect fit and exceptional aesthetic appeal in the final assembly.

Massive Production & Custom

We redefine mass production for the carbon fiber industry. We leverage advanced automation, modular mold design, and data-driven process control to achieve unparalleled efficiency and scale. Crucially, our flexible manufacturing cells allow for cost-effective customization within high-volume runs, enabling us to produce vast quantities of tailored components that consistently meet precise client specifications without compromising on quality or performance.

Integrated Aerospace Manufacturing & Engineering

Our 1.6m x 4m aerospace-grade autoclave (10 bar, 250°C) produces void-free carbon fiber components and matched CTE tooling, with full environmental logging ensuring end-to-end traceability. Supported by in-house design (Solidworks, Catia, FEA) and a reliable supply chain—including large pre-preg freezers—we seamlessly integrate precision machining and composite engineering for complex assemblies.

Uncompromising Quality Control

In-House Testing Laboratory

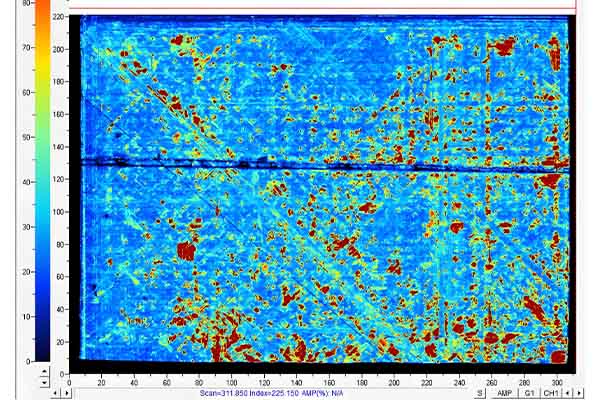

Water-coupled ultrasonic C-scanning is a non-destructive testing (NDT) method used to detect internal defects in Carbon Fiber Reinforced Polymer (CFRP). The component and transducer are immersed in water, which acts as an efficient acoustic couplant, ensuring consistent sound wave transmission. High-frequency ultrasonic pulses are sent into the material. Internal flaws such as delamination, porosity, or voids reflect these waves back to the sensor. The C-scan system then generates a detailed two-dimensional map, visually representing the size, shape, and depth of subsurface defects with high resolution.

Final Inspection

Every component undergoes a final, rigorous quality verification to ensure it meets all specified performance criteria. This comprehensive review includes a meticulous dimensional inspection against original CAD data using coordinate measuring machines (CMM), a final visual examination for surface integrity, and a review of all in-process quality records. For critical parts, this stage also includes validation via ultrasonic testing to confirm internal structural soundness. This ultimate checkpoint guarantees that only components fulfilling our strictest standards for precision, performance, and reliability are approved for shipment to our customers.

Why choose SCOMP composite?

Chinacarbonfibers thrives on speed and precision, transforming complex challenges into agile, custom-engineered solutions that accelerate productivity and secure your competitive edge.

Reach out today to explore how we can support your composite projects.

By selecting SCOMP Composites, you gain more than a supplier — you secure a committed partner focused on achieving your goals. Our proven experience serving world-class OEMs demonstrates our ability to deliver reliable, high-performance solutions. With SCOMP, you reduce project risk, leverage deep industry expertise, and foster collaborative relationships geared toward shared success.

Contact us to discuss your specific needs, and let our extensive experience bring value to your next venture.