¿Es la fibra de carbono conductora de electricidad? Datos importantes

El problema: comprender la conductividad de la fibra de carbono

Mucha gente Se confunden con la fibra de carbono. Se preguntan: "¿Conduce la electricidad?". No es una respuesta simple de sí o no.

Al trabajar con fibra de carbono, es necesario saber si conduce la electricidad. ¿Por qué? Porque:

- Los materiales incorrectos pueden causar grandes problemas

- Las piezas eléctricas necesitan la conductividad correcta

- Los problemas de seguridad ocurren con el decisiones equivocadas

Como creador de fibra de carbono piezas durante más de 28 años, vemos este problema con mucha frecuencia.

Los hechos sobre la conductividad de la fibra de carbono

Fibra de carbono ¿Conduce electricidad?Pero no como el metal. Veamos los hechos:

¿Qué tan conductora es la fibra de carbono?

La conductividad de la fibra de carbono varía entre 10² y 10⁴ S/cm, según el grado. Esto es mucho menor que el del cobre, pero mayor que el de la mayoría de los plásticos.

| Material | Conductividad | Usos |

|---|---|---|

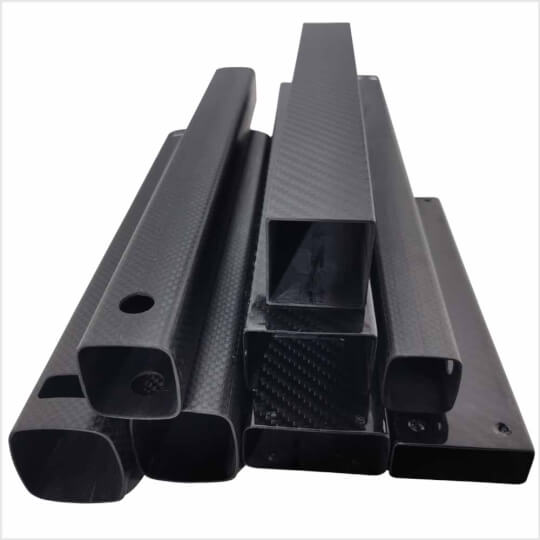

| Fibra de carbono pura | 10²–10⁴ S/cm | Material deportivo, piezas de coche |

| Fibra de carbono mejorada | Hasta 25.300 S/m | Aeroespacial, tecnología inteligente |

| Cobre | 5,96×10⁵ S/cm | Cables, electrónica |

¡La dirección importa!

La fibra de carbono conduce mejor la electricidad en una dirección que en otras. Conduce mejor a lo largo de la longitud de la fibraEsto es muy importante para fabricar piezas que necesitan conducir electricidad.

¿Qué afecta la conductividad de la fibra de carbono?

Estas cosas cambian la forma en que la fibra de carbono conduce la electricidad:

- Tipo de fibra – los diferentes tipos tienen diferente conductividad

- Volumen – más fibras significan mejor conductividad (15-20% mejor por cada 10% más de fibra)

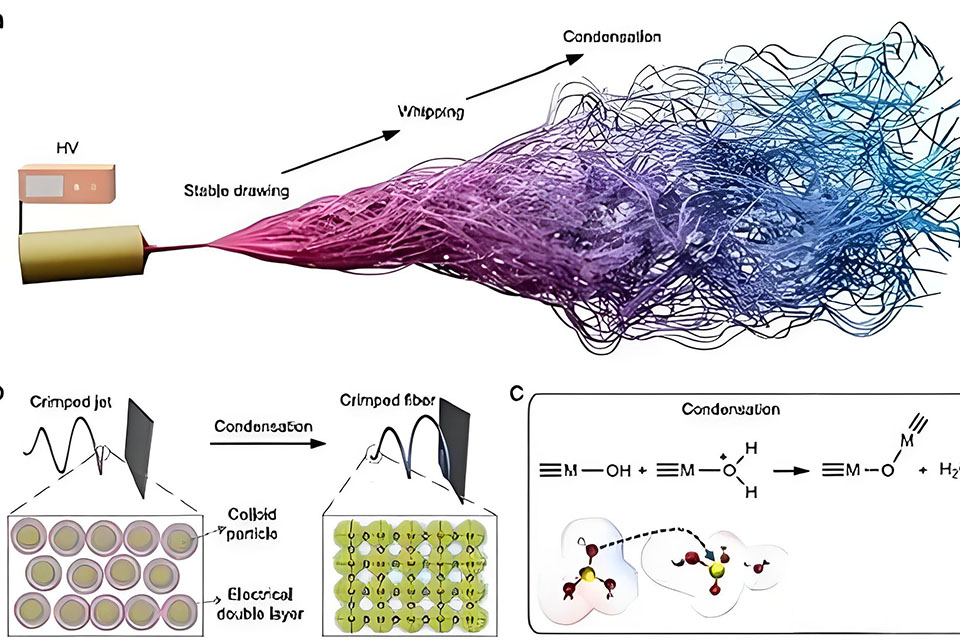

- Cómo se hace – algunos métodos lo hacen más conductor

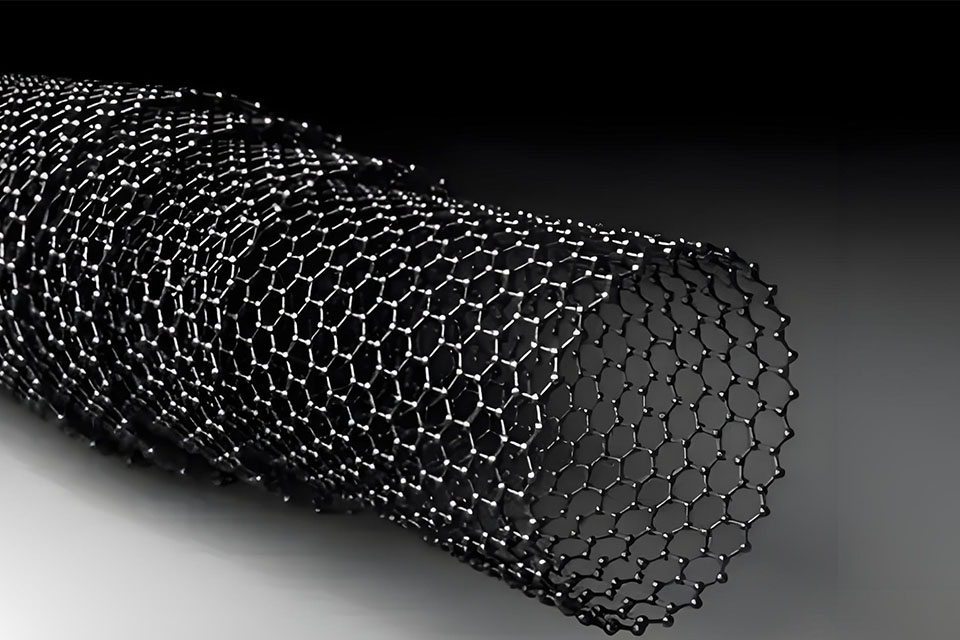

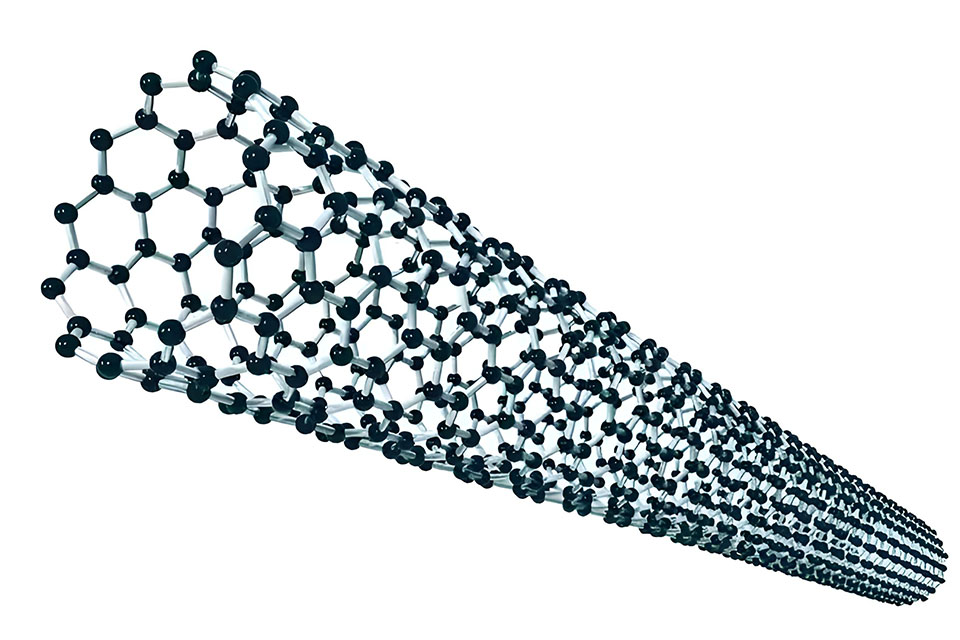

- Materiales añadidos – la adición de nanotubos de carbono puede hacerlo más conductor.

El problema empeora

Cuando no comprendes la conductividad de la fibra de carbono, pasan cosas malas:

- Las piezas fallan cuando deberían funcionar

- La electricidad estática se acumula

- Las piezas metálicas que tocan fibra de carbono se corroen 5 veces más rápido

- Los productos cuestan demasiado debido a materiales inadecuados

Muchos fabricantes se equivocan. Hemos visto fábricas que usan la fibra de carbono incorrecta y desperdician mucho dinero.

Por qué nuestras soluciones personalizadas de fibra de carbono funcionan mejor

Con Más de 28 años fabricando piezas de fibra de carbonoSabemos cómo resolver estos problemas. Nuestro fibra de carbono personalizada El servicio le ayuda a obtener la conductividad adecuada para sus necesidades.

Nuestras soluciones de fibra de carbono:

- Pruebas de expertos – Primero probamos tus necesidades

- Materiales adecuados – Elegimos el mejor tipo de fibra de carbono

- Fabricación inteligente – Utilizamos métodos que controlan la conductividad

- Recubrimientos especiales – Podemos añadir recubrimientos para detener problemas como la corrosión.

- Ahorro de costes – Te ayudamos a evitar errores costosos

Usos reales de la fibra de carbono conductora

Veamos cómo la fibra de carbono conductora ayuda en diferentes campos:

Coches y motocicletas

Nuestro coche de fibra de carbono y motocicleta de fibra de carbono Las piezas utilizan conductividad controlada para:

- Detener la acumulación de estática

- Ayuda con el blindaje EMI (bloqueo de ondas de radio)

- Hacer piezas más ligeras pero seguras

- Luce bien con menos peso

Aeroespacial y drones

Los aviones necesitan fibra de carbono especial que:

- Protege contra rayos (reduce el daño en 80%)

- Electrónica de escudos

- Se mantiene fuerte en cualquier clima.

- Pesa muy poco

Equipo deportivo

Raquetas de tenis, palos de golf y las bicicletas utilizan carbono fibra con:

- Conductividad suficiente para detener la estática

- Alta resistencia para un mejor rendimiento.

- Peso ligero para un juego más rápido.

Soluciones personalizadas para sus necesidades

Cada uso requiere una conductividad diferente. Nuestro servicio OEM/ODM le ayuda a conseguir exactamente lo que necesita.

Cómo fabricamos sus piezas de fibra de carbono:

- Nosotros escuchamos a lo que necesitas

- Hacemos pruebas para encontrar la conductividad correcta

- Nosotros hacemos utilizando los mejores métodos

- Nosotros comprobamos calidad en cada paso

- Nosotros entregamos A tiempo, siempre

Beneficios de trabajar con nosotros

Cuando trabajas con nuestra fábrica:

- Ahorrar dinero – Sin errores no hay desperdicio

- Ahorra tiempo – Más de 28 años de experiencia significan resultados más rápidos

- Consigue mejores piezas – nuestro control de calidad es muy estricto

- Resolver problemas – Te ayudamos a encontrar la conductividad adecuada

- Manténgase a la vanguardia – conocemos la última tecnología de fibra de carbono

Estudio de caso: Solución del problema de conductividad de un cliente

Un cliente necesitaba piezas para coches eléctricos. Sus piezas presentaban los siguientes problemas:

- Demasiada conductividad provocó cortocircuitos.

- Muy poca conductividad provocó acumulación de estática

- Las piezas metálicas se corroían rápidamente.

Lo arreglamos de la siguiente manera:

- Prueba de diferentes tipos de fibra de carbono

- Añadiendo la cantidad adecuada de nanotubos de carbono

- Utilizando un recubrimiento especial donde sea necesario

- Cambiando el proceso de fabricación

¿El resultado? Piezas que:

- Tenía justo la conductividad adecuada

- Cuesta 15% menos fabricarlo

- Duró 3 veces más

- Pesaba 20% menos

¿Por qué elegirnos para sus necesidades de fibra de carbono?

Con 28+ años En el negocio, conocemos la fibra de carbono al dedillo:

- Fabricamos piezas para grandes empresas en todo el mundo.

- Contamos con equipos de prueba de primer nivel.

- Controlamos todo el proceso de principio a fin.

- Podemos satisfacer cualquier necesidad de conductividad que tenga.

- Entregamos a tiempo, siempre.

Cómo empezar

¿Listo para obtener piezas de fibra de carbono con la conductividad adecuada? Aquí te explicamos cómo:

- Cuéntanos lo que necesitas

- Nosotros comprobamos Si la conductividad es importante para usted

- Te sugerimos la mejor solución

- Nosotros hacemos una muestra para ti

- Nosotros producimos tus partes cuando estás feliz

Conclusión: Cómo resolver los problemas de conductividad de la fibra de carbono

La conductividad de la fibra de carbono puede ser confusa. Pero con nuestra ayuda, no tiene por qué ser un problema.

Nuestros más de 28 años de experiencia fabricando piezas de fibra de carbono nos permiten resolver sus problemas de conductividad. coches de fibra de carbono Para piezas personalizadas, nos aseguramos de que obtenga la conductividad correcta en todo momento.

¡Hable con nosotros hoy sobre sus necesidades de fibra de carbono!