Cómo reparar fibra de carbono rota: una guía sencilla para todos

Reparación de fibra de carbono Puede parecer difícil. ¡Pero no tiene por qué serlo! Con la ayuda adecuada kit de reparación y pasos, puedes arreglar un grieta o carbono dañado parte de ti mismo

¿Estás mirando una? área dañada En tu bicicleta de fibra de carbono ¿O una pieza de coche? ¡No te preocupes! Nuestro 28+ años haciendo fibra de carbono Significa que sabemos cómo ayudarte. reparar fibra de carbono ¡perfectamente!

El problema del daño a la fibra de carbono

Carbón fibra obtiene dañadoEs posible que veas:

- A grieta En tu tejido de carbono (sucede 65% del tiempo)

- Delaminación dónde capas separado (sucede 30% del tiempo)

- A rascar o raspar en la superficie (sucede el 5% del tiempo)

Estos problemas ocurren por golpes, daños ocultos, o cuando tu pesca con fibra de carbono postes u otros elementos se enfrentan a demasiada tensión.

Cuando tu coche de fibra de carbono labio frontal grietas, es molesto. Cuando tu amado M3 Las piezas de carbono muestran una fracturaSe siente terrible. Incluso podrías pedir ayuda. 1addicts.com, bimmerpost.com, e90post.com, f30post.com, m3post.com, zpost.com, 5post.com, 6post.com o 7post.com – ¡Pero tenemos una solución mejor!

Por qué el daño empeora las cosas (La agitación)

Cuando la fibra de carbono se rompe, genera graves problemas:

- El compuesto La estructura pierde su resistencia y durabilidad

- El suave tela asargada o tejer el patrón se ve mal

- El carbono dañado podría delaminar más

- Agua o grasa Puede entrar en el zona afectada

Hazlo tú mismo Las correcciones mal hechas hacen que las cosas se compliquen. peor! Si mezclas resina epoxídica y endurecedor incorrectamente, su reparación será 30-50% más débilSi no limpias el zona afectada correctamente, no lo logrará adherirse 80% de la época.

La solución: métodos expertos de reparación de fibra de carbono

Con 28+ años Fabricando fibra de carbono, podemos enseñarte la solución fácil o ayuda con reparaciones complejas. Nuestro fábrica En China se fabrica y repara de todo: carbón bicicleta de fibra partes a parabrisas componentes.

Componentes del kit de reparación de fibra de carbono para hacer uno mismo

Un buen kit de reparación de fibra de carbono debe incluir:

| Artículo del kit | Objetivo | Notas |

|---|---|---|

| Tejido de carbono | Reemplaza el material dañado | Ambos carbono tejido y carbono unidireccional opciones |

| Resina epoxídica + endurecedor | Bonos y sellos | Crea una unión fuerte y permanente |

| Papel de lija (80-grano 120) | Preparación de la superficie | Para crear una superficie lisa |

| Cinta retráctil | Compresión | Ayuda eliminar las burbujas de aire |

| Capa transparente | Refinamiento | Añade protección UV y brillo |

| Tijeras o cortador | Corte de la fibra de carbono | Para un modelado preciso |

Todo lo necesario debe estar incluido en el kit para una completa reparar. gracias de antemano ¡Para comprobar si tu kit tiene todos estos elementos!

Proceso de reparación de fibra de carbono paso a paso

Utilizamos un plan inteligente para reparar el daño de su fibra de carbono. realizable Incluso para principiantes:

Paso 1: Evaluar la magnitud del daño

Marca si es necesario reforzar la parte trasera o si Ese es el caso donde una simple reparación de la superficie es suficiente.

Paso 2: Prepare el área dañada

- Usar grano 80-120 papel de lija para limpiar la zona

- Eliminar cualquier burbuja, revestimiento, o grasa

- Asegúrate de que necesidad de eliminar todas las fibras sueltas

- Crear una superficie lisa para los nuevos materiales adherirse

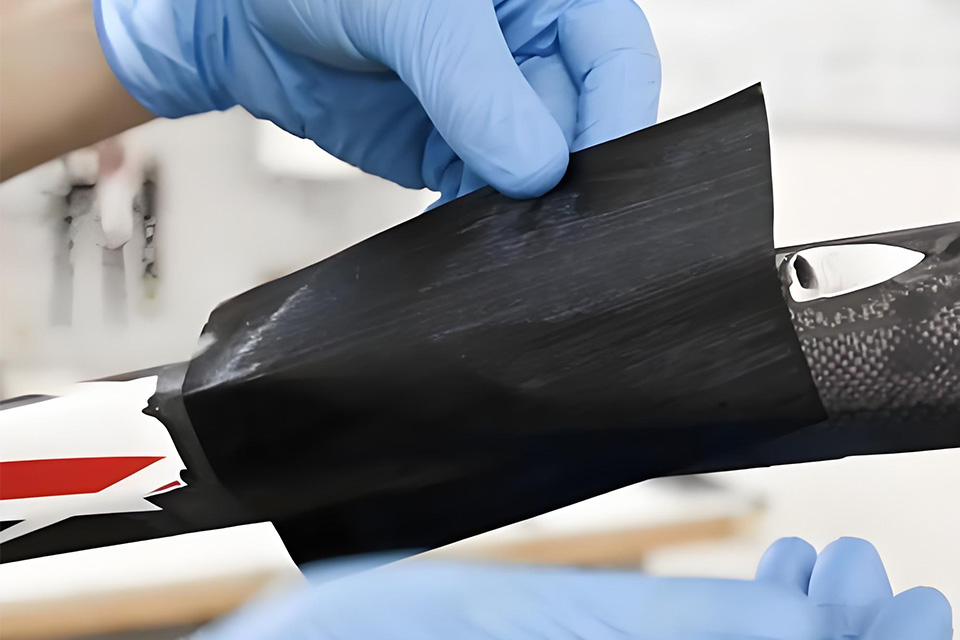

Paso 3: Aplicar los materiales de reparación de carbono

- Corta tu tejido de carbono con un cortar con tijeras o cortador

- Mezclar el cantidad apropiada de resina epoxídica y endurecedor

- Aplicar una fina capa de resina hacia área dañada

- Colocar en capas el tejido de carbono (usar varias capas para la fuerza)

- Añade otro capa de resina para saturar completamente el fibra

- Usar cinta retráctil o una bolsa de vacío Para eliminar burbujas de aire

Paso 4: Curar la reparación

- Deja que el resina epoxídica curar completamente (siga las instrucciones del kit)

- Algunas reparaciones se benefician del calor (use un pistola de calor con cuidado)

- Asegurar Curado adecuado para máxima resistencia

Paso 5: Acabado y pulido

- Una vez que el La reparación está hecha, lijar el área reparada liso

- Comience con grano 120 y vaya aumentando hasta granos más finos.

- Aplicar capa transparente para protección UV

- Suavizar y pulir Para que coincida con las áreas circundantes

Por qué nuestros productos de fibra de carbono nunca necesitan reparación

Nuestro fibra de carbono personalizada Los productos rara vez necesitan reparación porque:

- Utilice premium compuesto materiales

- Crea la perfección tejer patrones ya sea tela asargada o Hecho de unidireccional fibras

- Aplicar óptimo vacío técnicas para prevenir burbujas

- Asegúrese de que sea adecuado revestimiento para el máximo durabilidad

Aplicaciones reales para la reparación de fibra de carbono

Nuestros clientes utilizan estas técnicas en:

- motocicleta de fibra de carbono regiones

- Bicicleta de fibra de carbono marcos que grieta

- Cañas de pescar de fibra de carbono eso fractura

- Automotor vara componentes

- M3 Paneles de carrocería discutidos en m3post.com

Advertencia sobre humos y seguridad

Al trabajar con resina epoxídicaPor favor, tenga cuidado con humo Exposición. Trabaje en un área bien ventilada y siga las instrucciones de seguridad. incluido en el kit.

Ayuda experta cuando la necesitas

A veces Hazlo tú mismo No es suficiente. Las reparaciones complejas pueden requerir:

- Equipos especiales como bolsa de vacío sistemas

- De calidad profesional giratorio herramientas para el acabado

- Experiencia con fibra de vidrio refuerzo para daños severos

- PDF guías técnicas para tipos de reparación específicos

- Técnicas especiales para prevenir futuros delaminación

¡Llámenos ahora para una reparación experta de fibra de carbono!

Tu fibra de carbono dañada se puede arreglar! Ya sea que necesites un simple kit de reparación o un servicio profesional completo, nuestro equipo con 28+ años La experiencia puede ayudar.

Buscando algo más allá de lo simple reparar? También ofrecemos servicios completos fibra de carbono ¡Soluciones de fabricación!

Contáctanos hoy – ¡Tu fibra de carbono te lo agradecerá!