Nuestro eje de fibra de carbono es la mejor manera de tocando cue mejor. Como fibra de carbono superior planta de fabricación de productosfabricamos productos de alta calidad tacos de fibra de carbono para jugadores que quieren ganar más. Nuestro ejes son resistentes, ligeras y te ayudan a golpear la pelota con precisión en todo momento.

¿Por qué elegir nuestro flechas de fibra de carbono

- Mucho más resistentes que las varillas de madera

- No se deforman ni cambian con el calor

- Ayuda a golpear más tiros

- Duran muchos años

- Se ve muy bien

Nosotros hacemos fibra de carbono piezas para muchas grandes marcas en automóvil y motocicleta, aeroespacial, equipamiento deportivo, nuevas energías, equipamiento médico, decoración de edificios, electrónica de consumo, construcción naval y equipamiento industrial. Ahora le ofrecemos la misma calidad superior taco de billar.

Tecnología punta en fibra de carbono de 11,8 mm

Nuestro Eje de 11,8 mm utiliza lo mejor tecnología de fibra de carbono en el mundo. En eje está fabricado con fibras que lo hacen superresistente pero sin dejar de sentirse bien cuando juegas. El construcción de carbono de nuestra eje de juego le proporciona una mejor sensación y respuesta que viejo ejes de madera. Con nuestro eje de fibra de carbono, obtienes menos desviación al pulsar el botón bola blanca. Esto significa que entran más disparos.

Características principales de nuestra flecha de fibra de carbono de 11,8 mm:

| Característica | Beneficio |

|---|

| Filamentos de fibra de carbono multidireccionales que crean fortaleza | No se deforma, se mantiene recta para siempre |

| Baja deflexión diseño | Disparos más precisos, menos fallos |

| Perfecto 11.8 mm tamaño de la punta | Ideal para todo tipo de tomas |

| Placa de bóveda refuerzo | Mayor durabilidad en los puntos de tensión |

| Material de fibra de carbono con diseño espacial | Se ve increíble, se juega aún mejor |

"Desde que tengo este eje pro de fibra de carbonomi juego saltó dos niveles. El control de la bola blanca es increíble". - Tom, jugador profesional

Caña profesional de fibra de carbono de 12,4 mm para jugadores potentes

Si le gusta un poco más de peso en su juego, nuestro 12,4 mm eje profesional es la correcta. Este fibra de carbono pro le ofrece la combinación perfecta de potencia y precisión. Fabricado con fibra de carbono de grado aeroespacial, el 12.4 mm es perfecta para los jugadores que desean un golpe más fuerte. La conicidad profesional le ayuda a controlar cada golpe con menos esfuerzo. Este eje pro de fibra de carbono es utilizado por muchos jugadores de billar en los grandes partidos. Qué hace especial a nuestro eje de 12,4 mm:

- 15k fibra de carbono construcción para una resistencia suprema

- Perfecto conicidad profesional para la comodidad de las manos

- Especial virola que dura más que los normales

- Bajo mantenimiento necesidades - sólo limpiar

- Funciona con todos los taco de billar articulaciones Nuestra compuesto de carbono significa que este eje no cambiará de forma incluso después de miles de partidos. El antebrazo de arce teñido tiene un aspecto estupendo y ofrece el equilibrio de peso perfecto para los jugadores serios.

Eje especializado de 10,5 mm para una técnica de precisión

Para los jugadores que necesitan el control más preciso, ofrecemos una fina 10,5 mm nuevo eje con varillas de taco de billar de fibra de carbono tecnología. Esta flecha fina le ayuda a realizar tiros que otros tacos no pueden manejar.

El materiales compuestos de fibra de carbono que utilizamos proceden de las mismas existencias que suministramos a aeroespacial empresas. Esto significa que su cue ¡consigue la misma calidad que mantiene los aviones en el aire! El diseño fino y eje de carbono núcleo lo hacen perfecto para taco de salto o break cue usar también.

Especificaciones técnicas de nuestro eje de precisión de 10,5 mm:

| Especificación | Detalle |

|---|

| Diámetro | 10,5 mm consejo |

| Material del núcleo | Núcleo de espuma de poliuretano |

| Capa exterior | 15k fibra de carbono |

| Construcción | Doble núcleo con microcompresión |

| Finalizar | Esencia de perla revestimiento |

| Peso | 3,5 oz (superligero) |

El eje negro con metal de cañón acentos se ve increíble y le ayudará a eleve su juego a nuevas alturas. Este modelo incluye nuestro front-end diseño que le ofrece la trazo preciso posible.

Nuestros ejes de fibra de carbono proporcionan:

- No se deforma como ejes de madera

- Mejor puntería con desviación baja

- Golpe en el lomo y el uniforme cada vez

- La mejor sensación en el el mundo del billar

- Una forma de juego al siguiente nivel Como fabricante líder en tecnología de fibra de carbonoponemos todo nuestro saber hacer de tecnología y rendimiento del billar en estos ejes. Cada características del eje lo mejor en construcción compuesta y se somete a pruebas para garantizar que cumple nuestras estrictas normas.

Por qué elegir nuestros tacos de fibra de carbono

Nuestro fibra de carbono manufacturing plant has been making high-quality composite parts for many years. We understand how to work with remolque de fibra de carbono y otros materiales avanzados para crear productos con mejores prestaciones que las opciones tradicionales.

Cuando pida un taco o flecha de fibra de carbono de nosotros, se beneficiará de nuestra experiencia en muchos campos:

- Automóvil y motocicleta piezas de carbono que deben ser ligeras pero resistentes

- Aeroespacial componentes que deben cumplir estrictas normas de seguridad

- Equipo deportivo que da ventaja a los deportistas

- Equipamiento médico que salva vidas

- Electrónica de consumo que debe ser duradero

- Equipos industriales que funciona en condiciones difíciles

Esto significa que tu tocando cue recibe el mismo cuidado y calidad que las piezas de los coches deportivos y los aviones.

Opciones personalizadas disponibles:

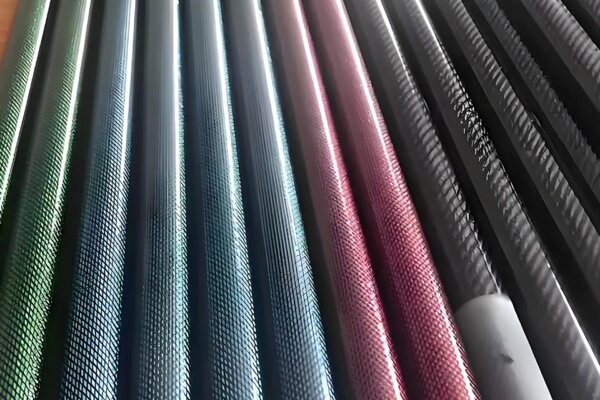

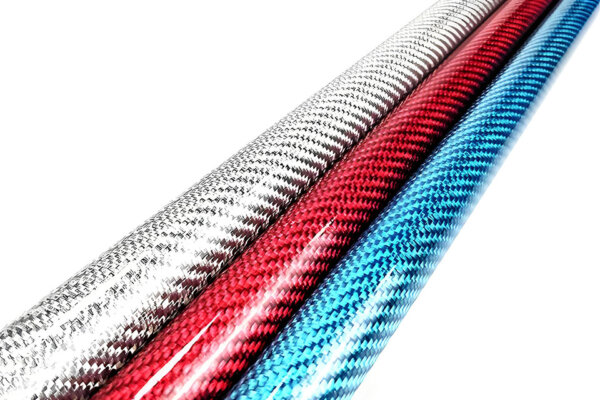

- Diferentes diámetros de punta (de 10,5 mm a 12,9 mm)

- Tipos de juntas que se adaptan a su taco actual

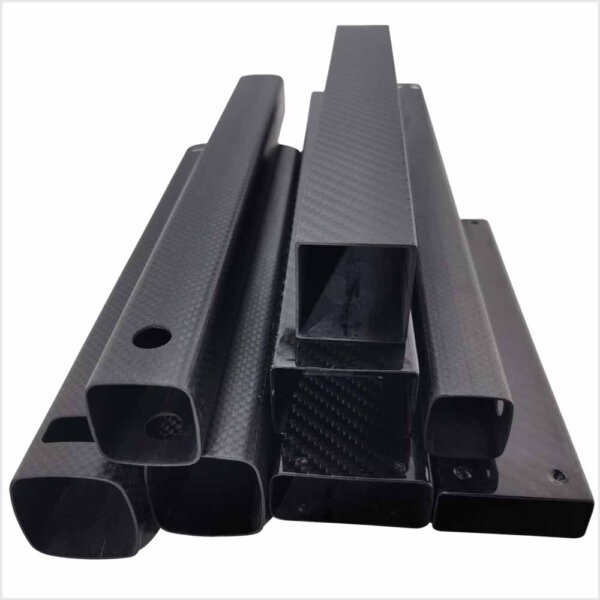

- Gráficos o colores personalizados

- Especial virola materiales

- Marca personal o de equipo

Nuestro pedido mínimo es de sólo 50 unidades, lo que nos hace perfectos para billar tiendas, equipos o distribuidores que quieran ofrecer la máxima calidad carbón eje de fibra productos a sus clientes.

Cómo se fabrican nuestras varillas de fibra de carbono

Hacer un perfecto taco de fibra de carbono requiere habilidad y un trabajo minucioso. Así es como lo hacemos:

- Seleccionar sólo perfecto fibra de carbono materiales

- Cortar y estratificar la fibra de carbono en nuestra sala blanca

- Colocar en moldes especiales que dan la exacta cónico

- Utilizar el calor y la presión para crear compuesto

- Máquina de dimensiones perfectas (como Eje de 11,8 mm)

- Añada el virola y acabado con nuestros revestimientos especiales

- Comprobación de la rectitud y el rendimiento de cada eje

- Empaquetar cuidadosamente para su envío a todo el mundo Este proceso garantiza que cada características del eje alineación y coherencia perfectas.

El taco presume rendimiento que la madera simplemente no puede igualar.

Opiniones de clientes sobre nuestras varillas de fibra de carbono

Nuestro fibra de carbono se han ganado los elogios de jugadores de todos los niveles. Esto es lo que dicen:

"Mi nuevo eje de carbono ha cambiado por completo mi juego. Los tiros que antes fallaba ahora son fáciles. El control de la bola blanca es increíble". - Mike, jugador de torneos

"He probado todas las grandes marcas fibra de carbono pro ejes, y éste es igual de bueno pero cuesta menos. Ahora todo mi equipo las usa". - Sarah, capitana del equipo

"Como billar propietario de una tienda, puedo decir que son el mejor valor en varillas de taco de billar de fibra de carbono. A mis clientes les encantan y vuelven a por más". - Bob, propietario de una tienda

"El 12,5 mm La varilla es perfecta para mi estilo de juego. Fuerte, recta y además tiene un aspecto estupendo". - James, Jugador de la Liga de Fin de Semana

Pida hoy sus ejes de fibra de carbono personalizados

Si quiere ofrecer a sus clientes lo mejor en taco de fibra de carbono tecnología, ahora es el momento de hacer su pedido. Nuestro eje de fibra de carbono productos dará a su empresa una ventaja competitiva. billar mercado.

Proceso de pedido:

- Póngase en contacto con nosotros

- Reciba un presupuesto en 24 horas

- Haga su pedido (mínimo 10 unidades)

- Aprobar la muestra que enviamos

- Comienza la producción

- Reciba su envío en 15-30 días Nuestro ofertas de taco las mejores prestaciones a precios competitivos. Y como somos fabricantes directos, obtendrá ahorros directos de fábrica sin intermediarios.

¡Póngase en contacto con nosotros ahora para elevar su negocio con los mejores ejes de fibra de carbono disponibles!

Resumen

Nuestra prima ejes de fibra de carbono ofrecen a los jugadores de billar una gran ventaja gracias a su diseño resistente y sin alabeo y a su increíble control de la bola. Fabricadas por los mismos expertos que crean piezas para la industria aeroespacial y los coches deportivos, estas varillas le ayudarán a realizar más tiros y a quedar bien haciéndolo. Prepárese para ganar más partidas.