¿Es la fibra de carbono más ligera que el plástico? Datos clave

El gran problema: las piezas pesadas te frenan

¿Te sientes estancado? con partes que son demasiado pesadoMucha gente usa piezas de plástico que:

- Romper demasiado rápido

- Pesar demasiado

- Parece barato

- Cuesta más enviarlo

- Hacer que las máquinas funcionen más lentamente

Este es un gran problema Para coches, aviones, bicicletas y muchas cosas más.

Por qué esto perjudica su negocio

Las piezas pesadas significan:

- Tus coches usan más gas

- Tus aviones vuelan viajes más cortos

- Tus bicicletas se sienten demasiado pesado

- Sus costos de envío son demasiado alto

- Tus clientes son no feliz

Cuando las piezas son demasiado pesadas, perder dinero. También perder clientesEl mundo quiere cosas que sean ligero y fuerte.

La solución perfecta: fibra de carbono de SCOMP

En SCOMP hemos hecho piezas de fibra de carbono para 28+ añosPodemos hacer piezas personalizadas que son mucho más ligero que el plástico.

Veamos por qué. fibra de carbono Es mejor que el plástico.

Fibra de carbono vs. plástico: Los hechos

Tabla de comparación de pesos

| Material | Densidad (g/cm³) | Qué ligero se siente | Mejores usos |

|---|---|---|---|

| Fibra de carbono | 1.55-1.75 | Muy ligero para lo fuerte que es | Aviones, coches de carreras, motos. |

| Plástico (PE) | 0.92-0.97 | Ligero pero no fuerte | Bolsas, juguetes, tazas |

| Plástico ABS | 1.03-1.06 | Peso medio | Fundas para teléfonos, piezas de automóviles |

Resultados de pruebas del mundo real

Cuando probamos piezas en la vida real:

- Piezas de drones:La fibra de carbono es Encendedor 35% que el plástico

- Paneles de coche:Nuestra fibra de carbono hace coches 40% más ligero en puntos clave

- Cascos deportivos: Reducción de peso del 15% con nuestra mezcla de fibra de carbono

- Palas de turbinas eólicas: Encendedor 20% que el plástico de fibra de vidrio

Por qué la fibra de carbono triunfa (aunque parezca más pesada)

Esto es extraño pero cierto: la fibra de carbono tiene una mayor densidad que algunos plásticos, pero las piezas terminan mucho más ligero.

¿Cómo puede ser esto? El secreto está en el diseño:

- La fibra de carbono es tan fuerte podemos usar mucho menos de ello

- Podemos hacer partes huecas Ese plástico no puede igualar

- Fibra de carbono no se flexiona Para que las piezas puedan ser más delgadas

Esto significa que una pieza de fibra de carbono puede ser Encendedor 30-50% que la misma pieza de plástico.

Nuestros mejores productos de fibra de carbono

1. Piezas de coche de fibra de carbono

ProblemaLos fabricantes de automóviles necesitan fabricar coches más ligeros para consumir menos gasolina.

Como dueleLos automóviles pesados cuestan más mantenerlos y dañan el planeta.

Nuestra soluciónNuestras piezas de fibra de carbono para automóviles reducen el peso en 40%, lo que hace que los automóviles funcionen mejor.

2. Piezas de motocicleta de fibra de carbono

Problema:Las bicicletas con piezas de plástico se rompen demasiado.

Como dueleLos ciclistas se estrellan cuando se rompen piezas y las bicicletas parecen baratas.

Nuestra soluciónNuestras piezas de fibra de carbono son 5 veces más resistentes que el acero pero mucho más ligeras.

3. Productos de fibra de carbono personalizados

ProblemaNecesitas piezas hechas especialmente para ti.

Como duele:Las piezas originales no encajan correctamente o no funcionan bien.

Nuestra solución:Realizamos cualquier forma que desees, sólo para ti.

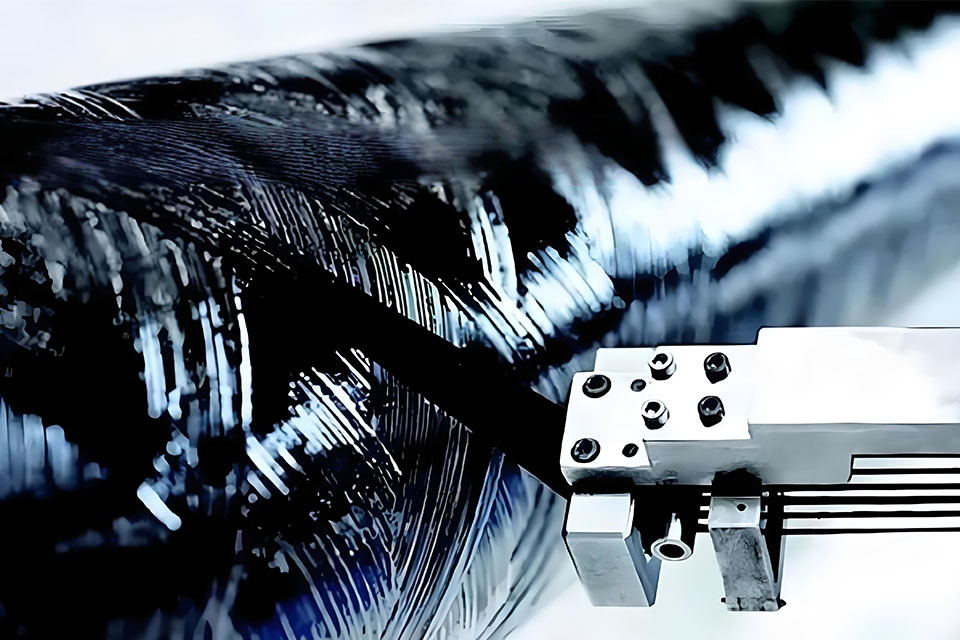

Cómo hacemos magia con la fibra de carbono

Nosotros usamos plástico reforzado con fibra de carbono (CFRP) Para hacer las mejores piezas:

- Nosotros envolver fibras de carbono de formas especiales

- Añadimos resina que lo mantiene todo unido.

- Lo horneamos para que quede súper fuerte.

- Le damos la forma perfecta para que se ajuste perfectamente

¿El resultado? Piezas que son ligero como una pluma pero fuerte como el acero.

Historias reales de clientes satisfechos

Fabricante de drones en EE. UU.

Cambiamos nuestros rotores por fibra de carbono SCOMP. Nuestros drones ahora vuelan 27% durante más tiempo. ¡A nuestros clientes les encanta!

Equipo de carreras de coches en Europa

Los paneles de carrocería de fibra de carbono de SCOMP redujeron el peso de nuestro coche en 54 kilos. ¡Ganamos tres carreras más este año!

Tienda de bicicletas en Australia

Los cuadros de fibra de carbono parecen inexistentes. Nuestras ventas han aumentado un 40% desde que cambiamos a piezas SCOMP.

El futuro de la fibra de carbono (¡cada vez mejora!)

El mundo de la fibra de carbono está creciendo rápidamente:

- El mercado crecerá 10,9% cada año de 2025 a 2030

- Para el año 2025, 15% más coches utilizará fibra de carbono

- La fibra de carbono reciclada costará 30% menos para 2025

Esto significa que la fibra de carbono será más común y menos costoso.

Lo que podemos hacer por usted

Nuestra fábrica puede fabricar cualquier pieza de fibra de carbono que necesite:

- Piezas de coche:Capós, parachoques, alerones

- Piezas de bicicleta:Cuadros, ruedas, manillares

- Piezas de drones: Rotores, brazos, cuerpos

- Artículos deportivos: Raquetas, bates, bastones

- Dispositivos médicos: Piezas ligeras y limpias

- Proyectos personalizadosTú lo sueñas, nosotros lo hacemos

¿Por qué elegir SCOMP para fibra de carbono?

- 28+ años fabricación de piezas de fibra de carbono

- Expertos en OEM/ODM que saben cómo hacer las cosas bien

- Diseños personalizados Hecho solo para ti

- Materiales de primera calidad para obtener los mejores resultados

- Entrega rápida Para mantener su proyecto en marcha

- Precios justos que tengan sentido para su presupuesto

Cómo funciona nuestro proceso

- Hablar:Díganos qué necesita

- Plan:Diseñamos la pieza perfecta

- PruebaNos aseguramos de que funcione

- Hacer:Construimos tus piezas

- Barco:Te los enviamos rápido

- ApoyoTe ayudamos si necesitas más

Preguntas frecuentes sobre la fibra de carbono

¿Realmente vale la pena el costo de la fibra de carbono?

¡Sí! Si consideramos la vida útil total de una pieza, la fibra de carbono cuesta menos porque:

- Dura mucho más

- Hace que las cosas funcionen mejor.

- Reduce los costes de combustible

- Se ve mejor para los clientes.

¿Puedes copiar mi pieza de plástico en fibra de carbono?

¡Sí! Podemos fabricar su pieza de plástico con la misma forma en fibra de carbono. Será más ligera y resistente.

¿Cuánto más ligeras serán mis piezas?

La mayoría de las piezas serán Encendedor 30-50% cuando se fabrica con nuestra fibra de carbono en lugar de plástico.

¿Tenéis pedidos mínimos?

Trabajamos con pedidos de todos los tamaños. ¡Permitimos pequeñas pruebas!

Consigue tus piezas de fibra de carbono ahora

No permita que las pesadas piezas de plástico limiten el rendimiento de sus productos. Cámbiese a la fibra de carbono y:

- Haz tus productos encendedor

- Haz que tus clientes más feliz

- Haz tu negocio más fuerte

Contáctanos hoy para obtener una cotización gratuita de sus piezas de fibra de carbono.

¿Por qué ahora es el momento de utilizar fibra de carbono?

El mundo busca productos ligeros, resistentes y respetuosos con el medio ambiente. La fibra de carbono cumple con todos estos requisitos.

Con nuestro 28+ años de conocimientos técnicos y nuestra servicios personalizadosPodemos ayudarle a realizar el cambio del plástico a la fibra de carbono.

Tu competencia ya está dando el salto. No te quedes atrás con piezas de plástico pesadas y frágiles.

Elige la opción inteligente. Elige la fibra de carbono SCOMP.