Heeft u last van deze problemen?

- Jouw ultralichte is te zwaar om te voldoen aan de regels van Deel 103

- Jouw vliegtuig kost te veel bouwen of kopen

- Je hebt nodig onderdelen die lang meegaan maar voeg geen gewicht toe

- Je wilt een tweezits ontwerp maar kan er geen vinden die aan de regels voldoet

Veel piloten voelen zich vastgelopen. Ze willen vliegen, maar de regels maken het moeilijk. Deel 103 zegt dat je vliegtuig leeg minder dan 254 pond moet wegen. Dat is niet veel! En als je twee stoelen wilt? Nog moeilijker!

Waarom dit je pijn doet

Wanneer uw ultralichte fiets te zwaar is:

- Jij de regels breken

- Jij betaal meer voor gas

- Jouw vliegtuig vliegt erger

- Misschien heb je een vliegbrevet

De meeste onderdelen gebruiken oude materialen zoals staal of aluminium. Deze voegen teveel gewicht toe. En als je twee stoelen probeert te plaatsen? Dan zit je al ver over de limiet!

De kosten blijven stijgen. Een Corsair kost $89,000 en een Helix $190,000! Dat is te veel voor de meeste mensen.

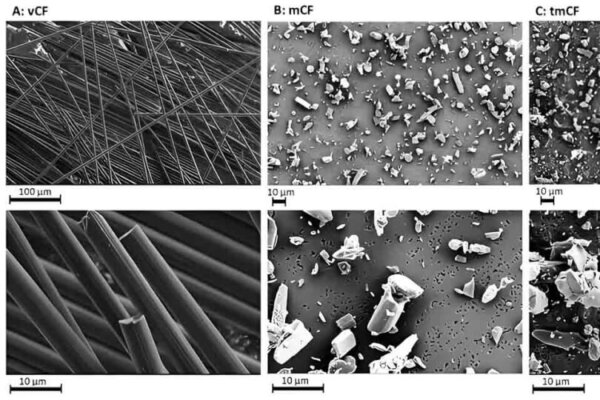

Koolstofvezel is uw antwoord

Wij maken aangepaste koolstofvezel onderdelen die deze problemen oplossen! Onze koolstofvezel onderdelen zijn:

- Superlicht – 70% lichter dan staal

- Zeer sterk – zal niet buigen of breken

- Speciaal voor jou gemaakt – past precies bij uw ontwerp

- Langdurig – zal niet roesten of slijten

Top ultralichte modellen met koolstofvezel

Kijk eens wat de beste vliegtuigen gebruiken:

| Vliegtuignaam | Wat het heeft | Hoeveel weegt het? | Wat maakt het speciaal? |

|---|

| Zeerover | Carbon buizenframe | Voldoet aan Deel 103 | Heeft een coole radiale motor |

| Zwaan 240 | 98% koolstofvezel | Twee stoelen (speciale regels nodig) | Opvouwbaar voor eenvoudige opslag |

| Belite | Koolstof + staal mix | Minder dan 254 pond | Volledig dashboard, veilig frame |

| Zwaan LE | Alle koolstof | Onder Deel 103 | Klaar om te vliegen |

Waarom onze koolstofvezelonderdelen winnen

Wij maken allerlei onderdelen:

- Buisframes

- Vleugelliggers

- Firewall-onderdelen

- Luifelframes

- Landingsgestel

- Stoelen en bedieningselementen

Hoe wij u helpen uw droomvliegtuig te bouwen

Ons aangepaste koolstofvezel service werkt in 4 eenvoudige stappen:

- U stuurt ons uw ontwerp – tekeningen, oude onderdelen of gewoon ideeën

- Wij maken een testonderdeel – perfecte pasvorm, ultralicht

- Je test het – kijk hoe het werkt op jouw vliegtuig

- Wij maken uw eindproduct – klaar om te installeren

Onderdelen die uw grootste problemen oplossen

1. Gewichtsproblemen? Opgelost!

Ons koolstofvezel buis frames wegen slechts 30% van stalen frames. Een hele set buizen kan je 20-40 pond besparen. Dat is het verschil tussen legaal en niet legaal!

"Ik was 15 pond zwaarder dan Deel 103. Uw koolstofvezel schutbord en buizen kreeg me onder de limiet met ruimte over!" - Tom B.

2. Tweezitsontwerp? Wij kunnen helpen!

Het maken van een tweezits Part 103 is lastig. Maar onze onderdelen kunnen u helpen:

- Bouw volgens de Duitse 120kg-regels

- Maak een experimenteel kitvliegtuig

- Creëer een opvouwbaar ontwerp dat nog steeds aan de regels voldoet

De Swan 240 gebruikt 98% koolstofvezel om een tweezitter te maken die onder Europese regels werkt. Wij kunnen vergelijkbare onderdelen voor uw ontwerp maken.

3. Kostenproblemen? Opgelost!

Terwijl een nieuwe Helix $190.000 kost, kunt u met onze onderdelen uw eigen Helix bouwen voor een veel lagere prijs:

- Frameset: begint bij $1,500

- Vleugelspar set: begint bij $1,200

- Volledige carbonsetvanaf $2.000

Dat is veel minder dan wanneer je een kant-en-klaar vliegtuig koopt!

Koolstofvezel maakt betere vliegtuigen

Ons koolstofvezel 2-zits Part 103 ultralicht vliegtuig onderdelen geven u:

Beter vliegen

- Minder gewicht = betere start

- Sterkere onderdelen = veiliger vliegen

- Stijf frame = betere controle

- Minder flex = soepelere rit

Meer plezier

- Ziet er cool uit – glanzende koolstofvezel afwerking

- Voelt modern aan – hightech materialen

- Duurt langer - zal niet roesten of corroderen

- Minder gas – lichter vliegtuig verbruikt minder brandstof

Slimme waarde

- Minder werk – onderdelen passen meteen goed

- Minder kosten – dan kant-en-klare vliegtuigen

- Meer waarde – onderdelen gaan jaren mee

- Betere wederverkoop – koolstofvezelvliegtuigen worden voor meer verkocht

Wat onze onderdelen vervangen

| Oud gedeelte | Ons koolstofdeel | Gewicht bespaard | Kracht |

|---|

| Stalen buizen | Koolstofvezel buizen | 70% minder | Hetzelfde of beter |

| Aluminium ribben | Koolstofvezel ribben | 50% minder | 20% sterker |

| Houten spanten | Koolstofvezel spanten | 60% minder | 3x sterker |

| Metalen firewall | Koolstof firewall | 40% minder | Hittebestendiger |

Van eenvoudige onderdelen tot complete sets

Wij kunnen één onderdeel of een complete set maken:

- Enkele onderdelen – los een probleemgebied op

- Sectie kits – vleugels, staart, cockpit

- Volledige framekits – alle koolstof die je nodig hebt

- Aangepast ontwerp – werk samen met onze ingenieurs

Voor koolstofvezel auto onderdelen, gebruiken we dezelfde hoogwaardige materialen. Uw vliegtuig krijgt dezelfde kwaliteit als raceauto's!

Hoe te beginnen

- Stuur ons uw plannen – stuur uw ontwerpen per e-mail of per post

- Vraag een gratis offerte aan – wij vertellen u de kosten en gewichten

- Bekijk een voorbeeld – test onze kwaliteit

- Bestel uw onderdelen – op maat voor u gemaakt

Onze belofte voor koolstofvezelkwaliteit

Al onze onderdelen worden geleverd met:

- Gewichtsgarantie – wij vertellen u het exacte gewicht

- Pasgarantie – werkt met uw ontwerp

- Sterktetestrapport – kijk hoe sterk het is

- 2 jaar garantie – gratis vervanging als het defect raakt

Begin eerder met vliegen met onze onderdelen

Wacht niet jaren met bouwen. Onze onderdelen helpen u sneller klaar te zijn:

- Voorgemaakte onderdelen – klaar om te installeren

- Snelle verzending – 3-4 weken voor aangepaste onderdelen

- Gemakkelijk te verbinden – speciaal koolstoflijmsysteem

- Duidelijke instructies – stapsgewijze handleidingen

Bestel vandaag nog uw koolstofvezelonderdelen

Wilt u uw ultralichte project starten? Moet u gewichtsproblemen oplossen? Bent u op zoek naar tweezitsopties?

Neem vandaag nog contact met ons op voor een gratis offerte!

E-mailadres: [email protected] Whatsapp: +8613626191009