Получите спойлер своей мечты C300 Mercedes: лучшие обновления из углеродного волокна

Ваш C300 выглядят одинаково как и любой другой Мерседес на дороге?

Многие владельцы C300 сталкиваются с этим большая проблема. У вашей машины нет стиля, который показывает, кто вы. Задняя часть вашей машины выглядит плоский и скучный. Когда вы паркуетесь рядом с другими автомобилями C300, никто не сможет отличить ваш.

Это нехорошо для хорошая машина как у тебя!

Машина, которая стоит так дорого, не должна выглядеть как все остальные. Но правда в том, что она выглядит как все остальные.

![Mercedes C300 со спойлером из углеродного волокна]

Почему это портит внешний вид и ощущения от вашего автомобиля

У вашего C300 есть эти большие проблемы:

- Нет сзади прижимная сила на высоких скоростях

- Обычный вид который сочетается со всеми другими автомобилями C300

- Меньше стабильный на дороге на большой скорости

- Ниже стоимость перепродажи чем кастомные автомобили

Когда машины проезжают мимо вас на дороге, они видят просто еще один C300. Не тот специальный автомобиль так и должно быть.

Ваш автомобиль должен привлекать внимание! Но этого не происходит.

Решение: индивидуальные спойлеры из углеродного волокна, которые сделают ваш C300 выдающимся

Мы делаем индивидуальные спойлеры из углеродного волокна которые решают все эти проблемы! Наш изготовленное на заказ углеродное волокно детали изготовлены специально для вашего Mercedes C300.

Наши спойлеры дадут вашему автомобилю:

- Больше прижимной силы (до 15% и больше на высоких скоростях)

- А вид гоночного автомобиля который выделяет ваш автомобиль

- Лучше сцепление с дорогой когда ты едешь быстро

- Выше стоимость перепродажи (до $1,000 и больше)

Как топ производители деталей из углеродного волокна, мы знаем, как изготовить детали, которые идеально подойдут вашему автомобилю.

Лучшие стили спойлеров из углеродного волокна для C300, которые мы производим

Мы производим много видов спойлер из углеродного волокна для C300 Mercedes. Вот самые понравившиеся:

| Стиль спойлера | Лучшее для | Цена | Масса | Время установки |

|---|

| V Спойлер багажника | Уличный вид | Позвоните, чтобы узнать цену | 3,2 фунта | 30 мин. |

| Крыло в стиле AMG | Расовый взгляд | Позвоните, чтобы узнать цену | 4,5 фунта | 45 мин. |

| Спойлер для губ | Чистый вид | Позвоните, чтобы узнать цену | 2,1 фунта | 20 мин. |

| Крыло в стиле GT | Использование трека | Позвоните, чтобы узнать цену | 5,8 фунтов | 60 мин. |

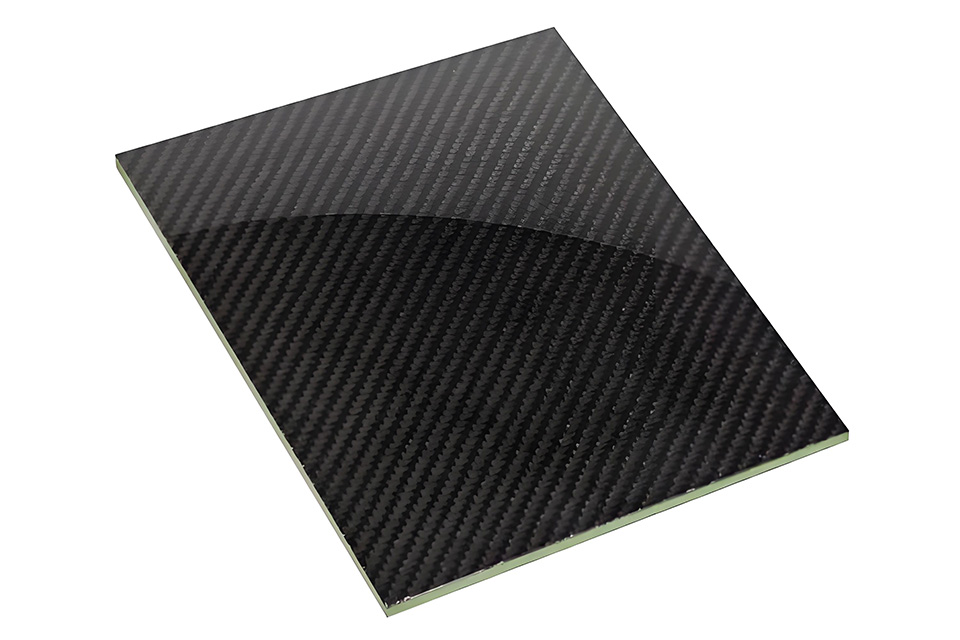

Все наши спойлеры сделаны из настоящее углеродное волокно с прозрачным покрытием, защищающим их от солнца и дождя.

Как наше производство углеродного волокна позволяет производить более качественные детали

Мы не просто продаем детали. Мы сделать их в нашем собственном магазине. Это означает:

- Мы используем высококачественное углеродное волокно (саржевое переплетение 3К)

- Мы можем сделать индивидуальный дизайн только для тебя

- Мы гарантируем, все части подходят правильно в первый раз

- Мы используем вакуумная инфузия для отсутствия пузырьков воздуха

- Мы добавляем Защита от ультрафиолета чтобы ваша часть оставалась блестящей

Мы делаем детали из углеродного волокна более 12 лет. Мы знаем, как их делать сильный и свет.

Почему владельцы C300 выбирают наши спойлеры из углеродного волокна

Наши клиенты говорят, что им нравятся наши спойлеры по следующим причинам:

- Идеально подходит – без пробелов и плохих линий

- Крепкое телосложение – не ломается и не трескается

- Чистовая отделка – никаких грубых краев

- Отличный вид – настоящий блеск углеродного волокна

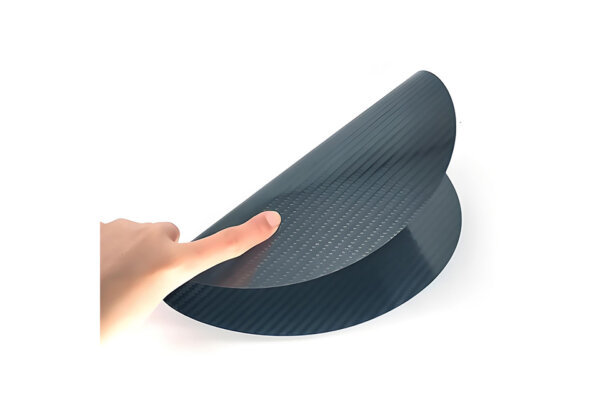

- Простая установка – большинство используют только ленту или болты

Мы продали более 5000 деталей из углеродного волокна для автомобилей Mercedes. Мы знаем, что работает!

Реальные данные пользователей показывают, как наши спойлеры помогают вашему автомобилю

Тесты с нашими спойлеры из углеродного волокна показать:

- 12% больше прижимной силы на скорости 120 миль в час

- 5% меньше шума ветра на скоростях шоссе

- 8% лучшая экономия топлива в дальних поездках (меньшее сопротивление)

- На 2,3 секунды быстрее время прохождения круга (тест на гоночной трассе)

Наши детали не только для внешнего вида. Они помогите вашему автомобилю работать лучше!

Как выбрать правильный спойлер для вашего C300

Выберите лучший спойлер, исходя из того, что вы хотите:

- Для ежедневное вождение: Выберите наш спойлер для губ

- Для шоу-кары: Получите наш спойлер V Style

- Для гонщики выходного дня: Попробуйте наше крыло в стиле AMG

- Для использование трека: Крыло в стиле GT лучше всего

Все подходит W204, W205 и W206 Модели C300 с 2008 по 2023 год.

Лучшие детали из углеродного волокна, подходящие к вашему новому спойлеру

Сделайте свой автомобиль еще лучше, добавив эти детали к спойлеру:

- Углеродное волокно задний диффузор – делает заднюю часть готовой к гонкам

- Боковые юбки – придает вашему автомобилю более низкий и широкий вид

- Передняя губа – делает переднюю часть соответствующей задней части

- Зеркальные крышки – небольшой штрих, показывающий внимание к деталям

- Крыша с пленкой – большой удар, который связывает все карбоновые детали вместе

Все они подходят к нашим спойлерам и сделают ваш автомобиль похожим на индивидуальная сборка.

Почему наш OEM/ODM-сервис лучше других магазинов

Мы не просто магазин. Мы завод углеродного волокна. Это означает:

- Мы можем сделать любую часть вы можете думать о

- У нас есть без посредников (экономит ваши деньги)

- Мы делаем настоящее углеродное волокно (не поддельный пластик)

- Мы можем копировать OEM-детали из углеродного волокна

- Мы делаем небольшие партии (не только крупные заказы)

Наш магазин может сделать одна часть только для вас или для тысяч для вашего магазина.

Как заказать индивидуальный спойлер из углеродного волокна для C300

Готовы сделать свой C300 выдающимся? Вот как:

- Выберите свой стиль из нашего автомобиль из углеродного волокна страница

- Выберите, хотите ли вы глянцевый или матовый оттенок.

- Добавьте другие части, которые вы хотите

- Оформите заказ

- Мы изготовим и отправим в течение 7-14 дней.

Мы осуществляем доставку во все страны и возвращаем все детали с Гарантия 2 года.

Что будет после обновления спойлера?

Как только вы увидите, насколько хорошо выглядит наше углеродное волокно, вам, возможно, захочется большего! Многие клиенты получают следующее:

Посетите наш главный углеродное волокно сайт, чтобы увидеть все, что мы можем сделать.

Не позволяйте вашему C300 выглядеть как все остальные на дороге. Приобретите спойлер из углеродного волокна и сделайте его особенным! Ваш Mercedes заслуживает того, чтобы выглядеть наилучшим образом.