الطباعة ثلاثية الأبعاد باستخدام ألياف الكربون: مستقبل الأجزاء القوية والخفيفة

المشكلة: الطباعة ثلاثية الأبعاد العادية ضعيفة للغاية

هل تصنع أشياء باستخدام طابعة ثلاثية الأبعاد؟ الأجزاء البلاستيكية العادية تنكسر بسهولةينحني، ينكسر، يفشل عندما تكون في أمس الحاجة إليه.

هذا هو سيء للغاية عندما تحتاج إلى أجزاء قوية لـ:

- السيارات

- طائرات بدون طيار

- أدوات

- أجزاء الآلة

البلاستيك العادي لا يفي بالغرض. إنه ضعيف جدًا. هذا يجعل الناس منزعج جدًا عندما تفشل أجزائها.

لماذا يؤثر هذا سلبًا على عملك

عندما تنكسر الأجزاء:

- أنت تهدر المال

- الزبائن يغضبون

- توقف المشاريع

- أنت تتخلف عن منافسيك

فكّر في الأمر. انكسرت قطعتك البلاستيكية أثناء عرض توضيحي مع عميل كبير. ماذا الآن؟ تبدو غير محترف. العميل يبتعد.

أو ربما تتحطم طائرتك بدون طيار بسبب انكسار ذراعها البلاستيكية. كل هذا العمل والمال - ذهب في ثوان.

الحل: الطباعة ثلاثية الأبعاد لألياف الكربون

Good news! Carbon fiber 3D printing fixes these problems when supported by engineering-grade carbon fiber manufacturing that turns printed designs into reliable, load-bearing parts. With our 28+ years making ألياف الكربون المنتجات، نحن نعرف كيفية صنع الأجزاء التي:

- هم أقوياء جدا

- ابقى خفيفًا

- تستمر لفترة طويلة

- تبدو جيدة

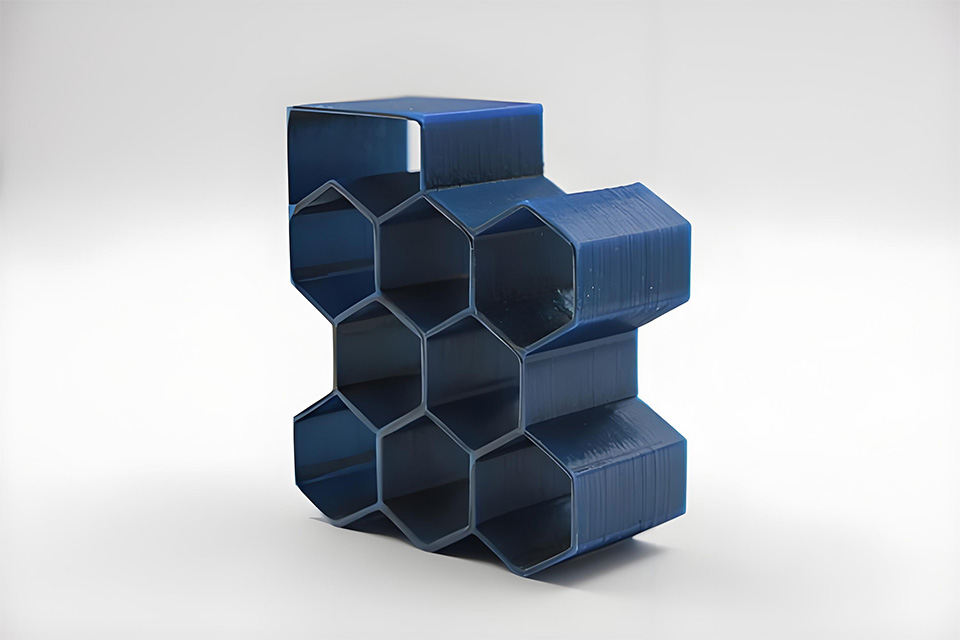

ما هي الطباعة ثلاثية الأبعاد لألياف الكربون؟

تمزج طباعة ألياف الكربون ثلاثية الأبعاد ألياف الكربون الدقيقة مع البلاستيك. وهذا يُنتج أجزاءً:

- أقوى بخمس مرات من البلاستيك العادي

- 3 مرات أكثر صلابة

- تقريبا مثل الضوء

تخيل الأمر كما لو كنتَ تضيف قضبانًا فولاذية إلى الخرسانة. ألياف الكربون تجعل البلاستيك أقوى بكثير.

أنواع الطباعة ثلاثية الأبعاد لألياف الكربون

هناك طريقتان رئيسيتان للطباعة ثلاثية الأبعاد باستخدام ألياف الكربون:

1. خيوط ألياف الكربون القصيرة

هذا هو النوع الأكثر شيوعًا. تختلط قطع صغيرة من ألياف الكربون مع البلاستيك مثل PLA أو النايلون أو PETG.

جيد ل:

- أسهل للطباعة

- يعمل مع العديد من الطابعات ثلاثية الأبعاد

- أرخص للبدء

2. ألياف الكربون المستمرة

يستخدم هذا خيوطًا طويلة من ألياف الكربون التي تمر عبر الجزء بأكمله.

جيد ل:

- أقوى بكثير أجزاء

- الأجزاء التي لا يجب أن تنكسر

- استبدال الأجزاء المعدنية

ما تحتاجه لطباعة ألياف الكربون ثلاثية الأبعاد

للطباعة باستخدام ألياف الكربون، تحتاج إلى:

| غرض | لماذا هو مطلوب؟ |

|---|---|

| فوهة من الفولاذ المقوى | ألياف الكربون تتآكل الفوهات العادية |

| وحدة تسخين عالية الحرارة | لألياف النايلون والكربون (250 درجة مئوية+) |

| سرير مُدفأ | يساعد على التصاق الأجزاء بشكل أفضل |

| الطابعة المغلقة | يحافظ على الحرارة للحصول على طبقات أفضل |

أفضل الطابعات ثلاثية الأبعاد لألياف الكربون

فيما يلي بعض الطابعات ثلاثية الأبعاد الجيدة لألياف الكربون:

| الطابعة | حجم البناء | الأفضل لـ |

|---|---|---|

| Raise3D Pro2 Plus | 305×305×605 مم | أجزاء صناعية كبيرة |

| QIDI Tech X-CF Pro | 300×250×300 مم | استخدام المصنع |

| مختبر بامبو X1E | 256×256×256 مم | جودة جيدة وتكلفة أقل |

الفوائد الحقيقية لطباعة ألياف الكربون ثلاثية الأبعاد

1. القوة عندما تحتاجها

أجزاء من ألياف الكربون أقوى بكثير من البلاستيك العادي. هذا يعني:

- لا مزيد من أذرع الطائرات بدون طيار المكسورة

- أجزاء السيارة التي يمكنها تحمل الضغط الحقيقي

- حاملات الأدوات التي لا تنكسر

ذراع طائرة بدون طيار لأحد العملاء، مصنوعة من البلاستيك العادي، انكسرت خلال ثلاثة أيام. أما نسختنا المصنوعة من ألياف الكربون، فقد صمد استخدامها لمدة ثمانية أشهر.

2. توفير الوزن

أجزاء ألياف الكربون خفيفة الوزن لكنها قوية. هذا يُساعد في:

- استخدام أفضل للوقود في سيارة من ألياف الكربون أجزاء

- أوقات طيران أطول للطائرات بدون طيار

- سهولة حمل الأدوات والأجهزة

3. مقاومة درجة الحرارة

يمكن لألياف الكربون والنايلون التعامل مع درجات حرارة أعلى بكثير من البلاستيك العادي:

- يعمل حتى 180 درجة مئوية (356 درجة فهرنهايت)

- لن يذوب في السيارة الساخنة

- جيد للأجزاء القريبة من المحركات

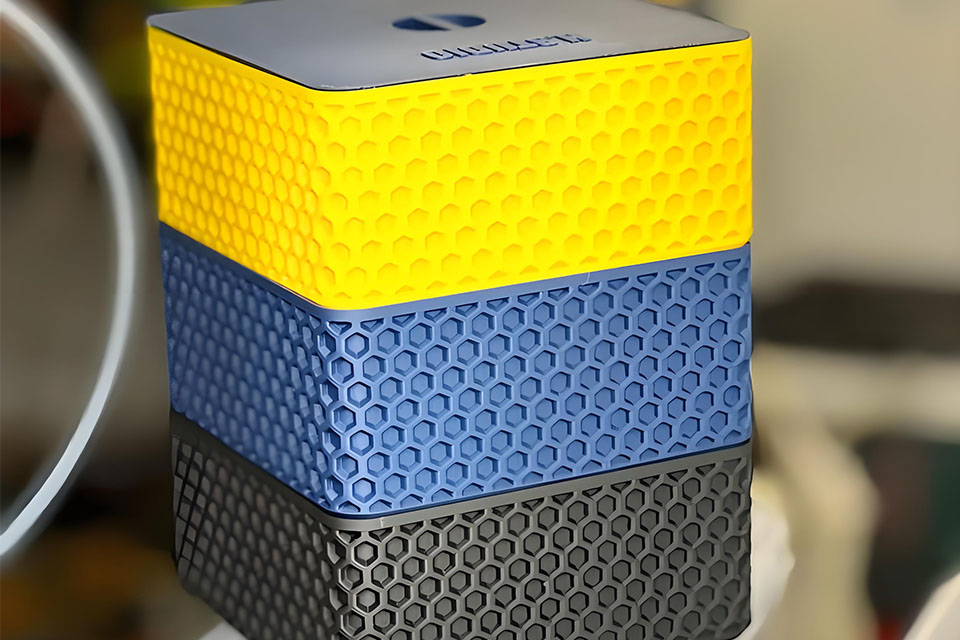

4. مظهر احترافي

ألياف الكربون لديها مظهر خاص الذي يقول "عالية الجودة":

- داكن مع نمط ألياف مرئي

- لمسة نهائية غير لامعة

- شعور ممتاز

هذا هو السبب وراء الكثير دراجة نارية من ألياف الكربون الأجزاء تبدو مذهلة.

المشاكل الشائعة وكيفية حلها

المشكلة: انسداد الفوهة (42% من المشكلات)

ألياف الكربون قاسية على الطابعات، وقد تسد فوهات الطباعة.

حلنا:

- نحن نستخدم فوهات فولاذية خاصة مقواة

- نقوم باختبار كل دفعة من الخيوط

- لدينا إعدادات مثالية للطباعة السلسة

المشكلة: ضعف ربط الطبقات (28% من المشكلات)

في بعض الأحيان لا تلتصق الطبقات ببعضها البعض بشكل جيد.

حلنا:

- نحن نستخدم إعدادات درجة الحرارة المثالية

- تحافظ حاوياتنا المخصصة على الحرارة في الداخل

- يمكننا تلدين الأجزاء بعد الطباعة للحصول على مزيد من القوة

المشكلة: التصاق السرير (18% من المشكلات)

يمكن لأجزاء ألياف الكربون أن تتشوه وتنفصل عن السرير.

حلنا:

- نحن نستخدم مواد سرير تم اختبارها لكل خيط

- طريقة تحضير السرير لدينا تعمل في كل مرة

- نحن نستخدم درجة حرارة السرير المناسبة فقط

الصناعات التي تستخدم الطباعة ثلاثية الأبعاد لألياف الكربون

الفضاء الجوي

- أجزاء الطائرات بدون طيار

- مكونات الأقمار الصناعية

- تجهيزات الطائرات

صانع طائرات بدون طيار خفض الوزن بمقدار 55% التحويل إلى أجزاء من ألياف الكربون.

السيارات

- أجزاء سيارات السباق

- قطع لوحة القيادة المخصصة

- أجزاء النموذج الأولي

ملكنا ألياف الكربون المخصصة ساعدت قطع غيار السيارات فريق سباق واحد وفر وزن 63% على المكونات الرئيسية.

طبي

- الأطراف الصناعية

- الأدوات الطبية

- أغلفة الأجهزة

أدوات شركة طبية تدوم 4 مرات أطول مع أجزاء ألياف الكربون الخاصة بنا.

صناعي

- أجزاء الروبوت

- تجهيزات المصنع

- أدوات مخصصة

مصنع واحد وفرت $45,000 سنويًا من خلال عدم كسر الأدوات البلاستيكية.

ميزتنا التصنيعية: أكثر من 28 عامًا من الخبرة

بخبرتنا التي تزيد عن 28 عامًا في تصنيع منتجات ألياف الكربون، ندرك تمامًا ما هو فعال. يقدم مصنعنا في الصين:

- تصميم مخصص بالكامل:نحن نساعدك في تحويل أفكارك إلى أجزاء حقيقية

- ضبط الجودة:100% فحص جميع الأجزاء

- تحول سريع:يتم التسليم خلال 2-3 أسابيع لمعظم الطلبات

- حجم:يمكننا صنع جزء واحد أو 10000

توفير التكاليف مع الطباعة ثلاثية الأبعاد لألياف الكربون

توفر الطباعة ثلاثية الأبعاد لألياف الكربون المال مقارنة بالطرق الأخرى:

تشغيل المعادن: $$$$$$$$$$$$$$$ 100% ألياف الكربون: $$$$$$$$$$ 85ألياف الكربون % 3د- الطباعة: $$$$$$ 40-65%

تحول أحد العملاء الذين يصنعون الأقواس المعدنية إلى أجزاءنا المطبوعة ثلاثية الأبعاد من ألياف الكربون وفر 55% على التكاليف.

كيفية البدء معنا

العمل معنا سهل:

- أرسل لنا فكرتك أو ملفك ثلاثي الأبعاد

- نقوم بمراجعته ونقترح أفضل نهج

- نحن نصنع عينة للموافقة عليها

- نبدأ الإنتاج عندما تكون راضيًا

دراسة حالة: شركة سباقات الطائرات بدون طيار

كانت شركة سباقات الطائرات بدون طيار تمتلك مشكلة كبيرةكانت أذرعها البلاستيكية تنكسر باستمرار عند هبوطها الاضطراري. انزعج الطيارون، وانخفضت المبيعات.

هذا أضر بأعمالهم كانوا ينفقون مبالغ طائلة على قطع الغيار. بدت علامتهم التجارية رخيصة.

لقد صنعناهم أذرع مطبوعة ثلاثية الأبعاد من ألياف الكربون الذي - التي:

- كنا أقوى بثلاث مرات

- بقيت نفس الوزن

- تكلفته فقط 15% أكثر من البلاستيك

- كان له مظهر كربوني رائع

نتائج:انخفضت الأعطال 94%. ارتفعت سعادة العملاء. وفرت $23,000 في السنة الأولى من مطالبات الضمان.

دراسة حالة: صانع الأجهزة الطبية

كانت لدى إحدى شركات الأدوات الطبية مقابض بلاستيكية:

- انكسر بسهولة

- لا يمكن تنظيفه بمواد كيميائية قوية

- بدا رخيصا

هذا أضرت بسمعتهم مع الأطباء. لقد خسروا المبيعات لصالح صانعي الأدوات المعدنية.

لقد ابتكرنا مقابض من ألياف الكربون والنايلون والتي:

- كانوا أقوياء مثل المعدن

- وقفت في وجه المواد الكيميائية للتنظيف

- كان لدي شعور ممتاز

- وزنه أقل من المعدن

نتائجارتفعت المبيعات بمقدار 34%. فضّل الأطباء الأدوات الجديدة. وفرضوا سعرًا أعلى بمقدار 20% مقابل الشعور بالجودة.

لماذا تختارنا كشريك طباعة ألياف الكربون ثلاثية الأبعاد؟

- خبرة أكثر من 28 عامًا:نحن نعرف ألياف الكربون أفضل من أي شخص آخر

- خبراء تصنيع المعدات الأصلية/تصنيع التصميم الشخصي:نحن نصنع أجزاءً تناسب احتياجاتك بالضبط

- خدمة كاملة:مساعدة في التصميم والنماذج الأولية والإنتاج

- ضبط الجودة:تم فحص كل جزء ثلاث مرات

- أسعار تنافسية:مباشرة من مصنعنا في الصين

هل أنت مستعد لصنع أجزاء أقوى؟

لا تدع الأجزاء البلاستيكية الضعيفة تؤثر على عملك بعد الآن. طباعة ألياف الكربون ثلاثية الأبعاد لدينا تُحل هذه المشاكل نهائيًا.

تواصل معنا اليوم للحصول على عرض سعر مجاني. أرسل لنا ملفك ثلاثي الأبعاد أو فكرتك. سنريك كيف يُمكن لألياف الكربون تحسين أجزائك.

بريد إلكتروني: [email protected] هاتف: +86-136 2619 1009 موقع إلكتروني: https://chinacarbonfibers.com