¿Se enfrenta usted a estos problemas?

- Tu ultraligero es demasiado pesado para cumplir con las reglas de la Parte 103

- Tu avión cuesta demasiado construir o comprar

- Necesitas piezas que duran pero no agregues peso

- Quieres una diseño de dos asientos pero no puedo encontrar uno que se ajuste a las reglas

Muchos pilotos se sienten estancadosQuieren volar, pero las reglas lo dificultan. La Parte 103 dice que el avión debe pesar menos de 114 kg vacío. ¡Eso no es mucho! ¿Y si quieres dos asientos? ¡Aún más difícil!

Por qué esto te duele

Cuando tu ultraligero es demasiado pesado:

- Tú romper las reglas

- Tú pagar más para gas

- Tu avión moscas peores

- Es posible que necesites una licencia de piloto

La mayoría de las piezas se utilizan materiales viejos Como el acero o el aluminio. Estos añaden demasiado peso. ¿Y si intentas meter dos asientos? ¡Ya pasaste el límite!

El El costo sigue subiendoUn Corsair cuesta $89,000 y un Helix $190,000. ¡Eso es demasiado para la mayoría!

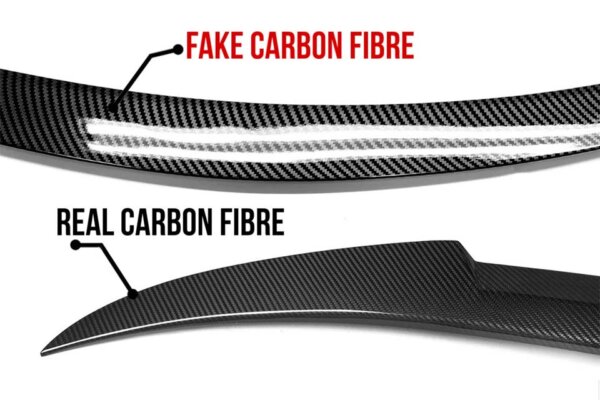

La fibra de carbono es tu respuesta

Nosotros hacemos fibra de carbono personalizada regiones ¡Que solucionen estos problemas! Nuestro fibra de carbono Las partes son:

- Súper ligero – 70% más ligero que el acero

- Acérrimo – no se dobla ni se rompe

- Hecho solo para ti – se ajusta exactamente a tu diseño

- De larga duración – no se oxida ni se desgasta

Los mejores modelos ultraligeros con fibra de carbono

Mira lo que usan los mejores aviones:

| Nombre del avión | Lo que tiene | ¿Cuánto pesa? | ¿Qué lo hace especial? |

|---|

| Corsario | Cuadro de tubo de carbono | Cumple con la Parte 103 | Tiene un motor radial genial. |

| Cisne 240 | 98% fibra de carbono | Dos asientos (requiere reglas especiales) | Se pliega para fácil almacenamiento. |

| Bélita | Mezcla de carbono y acero | Menos de 254 libras | Tablero completo, marco seguro |

| Cisne LE | Todo carbono | Según la Parte 103 | Listo para volar |

Por qué nuestras piezas de fibra de carbono triunfan

Nosotros hacemos todo tipo de piezas:

- Marcos de tubos

- Largueros de ala

- Partes del cortafuegos

- Marcos de dosel

- Tren de aterrizaje

- Asientos y controles

Cómo te ayudamos a construir el avión de tus sueños

Nuestro fibra de carbono personalizada El servicio funciona en 4 sencillos pasos:

- Nos envías tu diseño – dibujos, piezas antiguas o simplemente ideas

- Hacemos una pieza de prueba – ajuste perfecto, ultraligero

- Hazlo prueba – mira cómo funciona en tu avión

- Fabricamos tus piezas finales – listo para instalar

Piezas que solucionan sus mayores problemas

1. ¿Problemas de peso? ¡Solucionados!

Nuestro tubo de fibra de carbono marcos pesan sólo 30% de marcos de acero. Un juego completo de tubos puede ahorrarte entre 20 y 40 libras. ¡Esa es la diferencia entre legal y no legal!

"Estaba 15 libras por encima de los límites de la Parte 103. Su cortafuegos y tubos de fibra de carbono me dejó por debajo del límite con espacio de sobra". - Tom B.

2. ¿Diseño de dos asientos? ¡Podemos ayudarte!

Fabricar un biplaza Parte 103 es complicado. Pero nuestras piezas pueden ayudarte:

- Construido según las normas alemanas de 120 kg

- Haz un avión experimental en kit

- Crea un diseño plegable que aún se ajuste a las reglas

El Swan 240 utiliza fibra de carbono 98% para fabricar un biplaza que cumple con la normativa europea. Podemos fabricar piezas similares para su diseño.

3. ¿Problemas de costos? ¡Resueltos!

Si bien un Helix nuevo cuesta $190,000, puedes construir el tuyo propio con nuestras piezas por mucho menos:

- Kit de marco: a partir de $1.500

- Conjunto de largueros de ala: a partir de $1.200

- Juego completo de carbono: a partir de $2.000

¡Eso es mucho menos que comprar un avión ya fabricado!

La fibra de carbono permite fabricar mejores aviones

Nuestro Avión ultraligero de fibra de carbono de dos plazas, Parte 103 Las piezas te dan:

Mejor vuelo

- Menos peso = mejor despegue

- Piezas más fuertes = volar más seguro

- Marco rígido = mejor control

- Menos flexibilidad = viaje más suave

Más diversión

- Se ve genial – acabado de fibra de carbono brillante

- Se siente moderno – materiales de alta tecnología

- Dura más – no se oxida ni se corroe

- Menos gas – Un avión más ligero consume menos combustible

Valor inteligente

- Menos trabajo – las piezas encajan perfectamente la primera vez

- Menos costo – que los aviones ya preparados

- Más valor – las piezas duran años

- Mejor reventa – Los aviones de fibra de carbono se venden más caros

Qué reemplazan nuestras piezas

| Parte antigua | Nuestra parte de carbono | Peso ahorrado | Fortaleza |

|---|

| Tubos de acero | Tubos de fibra de carbono | 70% menos | Igual o mejor |

| Costillas de aluminio | Costillas de fibra de carbono | 50% menos | 20% más fuerte |

| Mástiles de madera | Largueros de fibra de carbono | 60% menos | 3 veces más fuerte |

| Cortafuegos metálico | Cortafuegos de carbono | 40% menos | Más resistente al calor |

Desde piezas sencillas hasta kits completos

Podemos fabricar sólo una pieza o un kit completo:

- Piezas individuales – solucionar un área problemática

- Kits de secciones – alas, cola, cabina

- Kits de fotograma completo – todo el carbono que necesitas

- Diseño personalizado – trabajar con nuestros ingenieros

Para coche de fibra de carbono Piezas, utilizamos los mismos materiales de alta calidad. ¡Tu avión tiene la misma calidad que los autos de carreras!

Cómo empezar

- Envíanos tus planes – envíe sus diseños por correo electrónico o correo postal

- Obtenga una cotización gratuita – te contamos costos y pesos

- Ver una muestra – prueba nuestra calidad

- Pide tus piezas – hecho a medida para ti

Nuestra promesa de calidad de fibra de carbono

Todas nuestras piezas vienen con:

- Garantía de peso – te decimos el peso exacto

- Garantía de ajuste – trabaja con tu diseño

- Informe de prueba de resistencia – mira lo fuerte que es

- Garantía de 2 años – reemplazo gratuito si falla

Empiece a volar antes con nuestras piezas

No espere años para construir. Nuestras piezas le ayudan a terminar más rápido:

- Piezas prefabricadas – listo para instalar

- Envío rápido – 3-4 semanas para piezas personalizadas

- Fácil unión – sistema especial de pegamento de carbono

- Instrucciones claras – guías paso a paso

Pida hoy sus piezas de fibra de carbono

¿Quieres empezar tu proyecto ultraligero? ¿Necesitas solucionar problemas de peso? ¿Buscas opciones biplaza?

¡Contáctanos hoy para una cotización gratis!

Correo electrónico: [email protected] Whatsapp: +8613626191009