Cubiertas de monopatín premium de fibra de carbono: El futuro del patinaje

Bienvenido a la siguiente nivel ¡del monopatín! Nuestra cubiertas de monopatín de fibra de carbono se fabrican en nuestra vanguardia fábrica. Fabricamos el el más fuerte, más ligero cubiertas que puedes comprar. Estos son no como los monopatines normales. Nuestras tablas te ayudan a patinar mejor y más extenso. Ellos no grieta como las cubiertas de madera.

Vendemos a grandes empresas que quieren la los mejores monopatines para sus clientes. Nuestras cubiertas de fibra de carbono son perfectas para tiendas, equipos y marcas que necesitan calidad superior.

Por qué la fibra de carbono es la mejor tabla de monopatín

El los mejores monopatines necesitan las mejores piezas. Nuestro cubierta de fibra de carbono es mucho mejor que un cubierta de madera. El carbono es encendedor pero más fuerte que la madera. Esto significa que puedes saltar más alto y hacer trucos mejor.

Nuestro ingeniero equipo hace cubiertas que son 5 veces más fuerte que arce tradicional cubiertas. Cuando recoja nuestro patineta de fibra de carbononotará la diferencia enseguida.

"He cambiado a todos mis riders profesionales a estas cubiertas de fibra de carbono. Duran más y funcionan mejor que cualquier otra cosa que hayamos probado". - Director de marca de monopatines

Cubierta de monopatín de fibra de carbono Características:

- Súper ligero - 30% más ligera que las cubiertas de arce

- Extra fuerte - Dura 5 veces más que la madera

- Pop perfecto - Mantiene su chasquido durante meses

- Impermeable - No se deforma con la humedad

- Buena pinta - Elegante carbón diseño

Cómo se fabrican nuestros patines de fibra de carbono

Nosotros hacemos nuestro tablas de skate con cuidado. Cada tabla de monopatín de fibra de carbono comienza con capas de fibra de carbono y fibra de vidrio. Los prensamos con un pegamento especial. De este modo se cubierta que es a la vez luz y fuerte. Nuestra fábrica utiliza norteamericano normas. Comprobamos cada tablero muchas veces. De este modo, se asegura de obtener sólo los el mejor monopatín cubiertas.

El nariz y cola de nuestras cubiertas están hechas para durar. Nosotros reforzarse estos puntos para que no se rompan cuando hagas trucos.

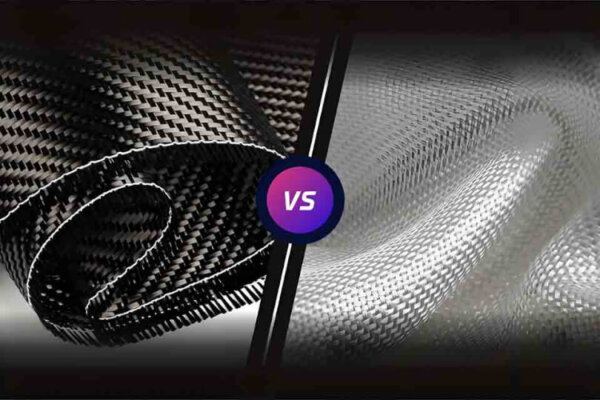

Carbono vs. Arce: Por qué los patinadores adoran nuestras cubiertas

| Característica | Cubierta de fibra de carbono | Estándar 7 capas Arce |

|---|

| Peso | 2,1 libras | 3,4 libras |

| Esperanza de vida | 6-12 meses | 1-2 meses |

| Daños por agua | Ninguno | Se deforma fácilmente |

| Retención Pop | Se mantiene ágil | Pierde pop rápidamente |

| Precio | Mayor coste inicial | Más bajo pero necesita reemplazo |

Nuestro cubiertas de monopatín de fibra de carbono mantener su pop mucho más tiempo que la madera. A patinador que prueba nuestras cubiertas casi nunca vuelve al arce.

Cubierta de vuelo de fibra de carbono: Para pilotos serios

Nuestro modelo estrella es el Cabina de vuelo. Este patineta de fibra de carbono es para jinetes que necesitan lo mejor. Es más rígido que nuestros otros modelos. Esto le da más control y capacidad de respuesta al hacer trucos.

El Cabina de vuelo tiene capas adicionales de carbón alrededor de los camiones. Esto evita que la tabla se rompa donde la mayoría de las cubiertas fallan.

Por qué los equipos profesionales eligen nuestras tablas de monopatín de fibra de carbono

Muchos equipos profesionales utilizan ahora nuestras cubiertas. Saben que una cubierta más resistente significa:

- Mejor rendimiento en concursos

- Menos tablas rotas durante grandes acontecimientos

- Tacto uniforme de tablero a tablero

- Costos más bajos con el tiempo (menos sustituciones)

- Patinadores felices que puede centrarse en los trucos, no en el equipo A patinador con nuestro cubierta de patín de fibra de carbono pueden centrarse en hacer trucos, sin preocuparse de romper la tabla.

"Cuando cambiamos a estas cubiertas de carbono, nuestras reclamaciones de garantía se redujeron en 85%. Los clientes están más contentos y vuelven a por más productos". - Propietario de una tienda de monopatines

Opciones de tamaño para cada estilo de patinaje

Fabricamos muchos tamaños de cubierta de monopatín. Desde pequeñas terrazas hasta grandes longboard estilos. El más popular es el 8.0″ cubierta. Funciona bien para la mayoría de los patinadores.

Todos los tamaños tienen el mismo fibra de carbono calidad. Usted obtener carbono fuerza sin importar el tamaño que elijas.

| Tamaño de la cubierta | Mejor para | Límite de peso |

|---|

| 7.5″ | Patinaje técnico de calle | Hasta 160 libras |

| 8.0″ | Patinaje integral | Hasta 200 libras |

| 8.5″ | Transición/patinaje en rampa | Hasta 230 libras |

| 9.0″+ | Crucero, longboard | Hasta 280 libras |

Nuestras cubiertas incluyen resbaladizo capa inferior. Esto les ayuda a deslizarse mejor sobre raíles y salientes. La página resbaladizo La superficie también se ve muy bien con los gráficos.

Cómo conseguir tus propios patines de fibra de carbono personalizados

Pedir cubiertas de monopatín de fibra de carbono para su marca o tienda? He aquí cómo:

- Contáctanos con tus necesidades

- Enviamos muestras de cubiertas para pruebas

- Elige tu tamaños y gráficos

- Hacemos tu pedido personalizado

- Disfrute vendiendo el los mejores monopatines en el mercado

El pedido mínimo es de 50 barajas. Podemos fabricar cubiertas de monopatín de fibra de carbono con sus propios gráficos y logotipos.

Por qué elegir nuestra fábrica para sus cubiertas de fibra de carbono

No solo hacemos cubiertas de monopatín. Nuestra fábrica fabrica fibra de carbono piezas para:

- Automóvil y motocicleta empresas

- Aeroespacial empresas

- Equipo deportivo marcas

- Equipamiento médico creadores

- Decoración de edificios proyectos

- Electrónica de consumo marcas

- Construcción naval empresas

- Equipos industriales fabricantes

Esta amplia experiencia significa que sabemos fibra de carbono mejor que nadie. Cuando quieras lo mejor cubiertas de monopatín de fibra de carbononos quiere a nosotros. Podemos ayudarle a sustituir su arce tradicional cubiertas con nuestro ágilfuerte cubierta de patín de fibra de carbono opciones.

El coste-beneficio de los monopatines de fibra de carbono

Mientras que un nueva cubierta hecho de fibra de carbono cuesta más al principio, pero ahorra dinero con el tiempo. Hagamos cuentas: Para una tienda de patines que vende 100 cubiertas al mes:

| Tipo de cubierta | Coste por cubierta | Sustituciones al año | Coste anual |

|---|

| Arce | $35 | 6 por patinador | $21,000 |

| Fibra de carbono | $45 | 1-2 por patinador | $8,750 |

| | | AHORRO: | $12,250 |

Sus clientes estarán encantados de comprar menos cubiertas mientras disfrutan de mejores monopatín actuación.

Empiece hoy mismo con las tablas de monopatín de fibra de carbono

¿Listo para llevar tu marca de monopatines al siguiente nivel? Nuestro cubiertas de monopatín de fibra de carbono dará a sus clientes una mejor experiencia.

Contáctanos ahora para obtener más información cubiertas de fibra de carbono. Podemos enviarle muestras para que las pruebe.

Correo electrónico: [email protected] Teléfono: +86-136 2619 1009 Sitio web: Fábrica de carbón

Más información sobre nuestros otros productos:

Resumen: Nuestras tablas de monopatín de fibra de carbono de alta calidad ofrecen 5 veces más resistencia, 30% menos peso y meses más de vida útil que las tablas de madera. Con una retención perfecta del pop, una construcción impermeable y opciones de personalización de la marca, nuestras cubiertas ayudan a las empresas de monopatines a ofrecer un rendimiento superior y a reducir las reclamaciones de garantía hasta en 85%.