There’s a reason more players—from academy prospects to veterans—are switching to carbon fiber shin guards. When a game turns on a single 50/50 challenge, you want maximum protection without sacrificing agility. At Fibras de carbono de China, we build gear for players who refuse to pick between speed and safety. Our carbon fiber shin pads combine an ultralight shell with advanced impact dispersion so you sprint, cut, and tackle with confidence—match after match.

Why Carbon Fiber Shin Guards Are Changing the Game

Traditional plastic shin guards (polypropylene or fiberglass shells with EVA foam backing) are affordable, but they’re prone to flexing, cracking, and bulk. Carbon fibre (CFRP) flips that trade-off: it delivers higher stiffness-to-weight and better energy distribution at a fraction of the thickness. The result is a low-profile, ultra-light guard that disappears under your sock yet feels rock-solid when the first heavy challenge lands.

- Strength-to-weight advantage: thinner shell, stronger protection

- Lower bulk: fewer pressure points, reduced chafing, cleaner ball feel

- Faster acceleration: every gram saved means snappier starts and quicker changes of direction

Advanced Impact Resistance — Absorbs up to 90% of Force

A properly engineered carbon shell + performance foam stack acts like a force management system. The carbon fibre distributes the hit across a larger area; the foam (EVA, Poron, or neoprene blends) decays the peak load before it reaches your shin. In controlled lab conditions with standardized drop tests, well-built carbon guards can reduce transmitted force by up to ~90% compared to the raw impact—far beyond what most plastic plates can achieve.

Trusted by Professionals — From Premier League to Sunday Leagues

From pro academies to Sunday League grinders, players choose carbon pads for the same reasons: lighter feel, tougher shell, cleaner fit. Many top athletes favor minimalist, slip-in shinguards paired with grip socks and anti-slip sleeves—a setup that’s snug, breathable, and compliant with league rules (UEFA/FIFA: guards under socks, no sharp edges, adequate coverage). If you’re aiming for elite habits on a practical budget, carbon is the most meaningful upgrade you can make to lower-body protection.

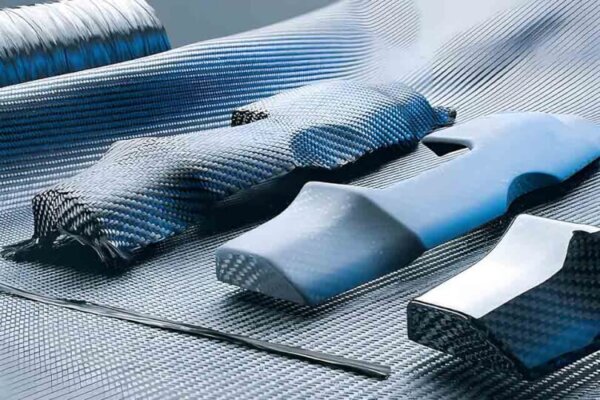

The Science Behind Carbon Fiber Reinforcement (CFRP)

CFRP (Carbon-Fiber Reinforced Polymer) combines continuous carbon filaments with a thermoset resin. Compared with plastic, CFRP offers:

- High specific stiffness/strength: resists denting and permanent deformation

- Superior fatigue behavior: maintains performance under repeated loads

- Thermal stability: less creep or softening in heat (summer pitches, turf)

- Directional tailoring: by orienting weaves/plies (0/90/Twill), engineers tune flex and impact behavior

For shin guards, that means a thin shell that still shrugs off studs, knees, and stray boots—everything the midfield chaos throws at you.

Our supply chain sources aerospace-grade prepreg weaves (twill or plain weave faces for aesthetics, structural core plies for performance). We partner with a fábrica de composites a medida to mate these materials to football-specific backers—EVA foam, Poron, or neoprene—to balance comfort, sweat management, and rebound damping. The outer face brings impact spread and fracture resistance; the inner pad manages micro-vibrations and hotspots so you can wear your guards for 90–120 minutes without thinking about them.

Every Gram Counts — Lighter Gear, Faster Movement

Shaving grams from the lower leg changes how you move: quicker toe-offs, faster cuts, less late-game fatigue. Carbon pads are typically lighter than plastic at higher protection levels, so you don’t need to choose between “fast” and “safe”—you get both.

Choosing the Right Carbon Fiber Shin Guards

Size & Fit Guide — How to Measure Your Shins

Proper fit is non-negotiable for protection and comfort.

- Length: Measure from ~3 cm below the patella to the top of your ankle line.

- Calf profile: Note the widest calf circumference—helps pick a sleeve that won’t constrict.

- Shin curvature: If your tibia is prominent, prioritize contoured shells with scalloped edges.

Position/play style:

- Wingers/forwards: ultralight models for agility

- Defenders/DMs: wider coverage for aerials and blocks

- Youth: smaller size but full tibia coverage

Pro tip: Pair with grip socks and anti-slip sleeves for a locked-in feel.

Small, Mini or Full-Size Guards

- Mini / ULTIMA Mini (8 cm / 10 cm) — perfect for youth or futsal

- Regular / Midi — balanced coverage for most players

- Full-Size / Large — extra width for defenders and goalkeepers

Custom Molds & Personalized Design Options

Fibras de carbono de China offers:

- Personalized printing (name, number, flag, or crest)

- Custom colors and stealth weave finishes

- Fit personalization with mold tweaks

- Team bundles with unified design

For clubs and distributors, we align with CE marking and regional packaging requirements for retail.

Featured Models & Comparisons

Speed Demon® V3 Carbon Fiber Pro Guards

Built for Speed, Engineered for Safety — thin yet rigid multi-ply carbon shell, lab-tested 93% impact absorption.

ULTIMA Mini Carbon Fibre Shin Pads

Ultra-slim for mobility; perfect for futsal and youth players.

Patronus Elite Shin Guards

Premium personalization for academies and semi-pro squads.

Comparison with Adidas, Nike and Carbon Guards Pro

Major brands make excellent socks, boots, and sleeves; but for true carbon expertise, we go deeper—leveraging experience across automotive composites like coches de fibra de carbono. Compared with mainstream plastic guards, our carbon shells provide higher impact control at lower thickness, and unmatched craftsmanship through autoclave curing.

Proceso de fabricación de fibra de carbono

From Prepreg to Autoclave — How Shin Guards Are Made

- Prepreg layup

- Vacuum stack

- Autoclave cure

- Trim, polish, and laminate

- QC and retail packaging

Vacuum Bagging vs Autoclave Curing

Vacuum-only curing is cost-effective for training-grade models. Autoclave curing delivers pro-level fiber density and strength—our standard for top-tier guards.

Environmental Benefits and Durability

Carbon shells resist permanent deformation and last longer, reducing waste and lifetime cost—ideal for clubs buying in volume.

Are Carbon Fiber Shin Guards Worth It?

While carbon pads cost more initially, they deliver superior protection, longevity, and confidence. One pair often outlasts several plastic alternatives.

Care & Maintenance Guide

- Wipe with mild soap and air-dry

- Avoid machine washing or harsh heat

- Use sleeves for protection

- Replace if cracks or delamination appear

- Carbon Fiber Footless Socks — engineered for friction control and perfect pairing with shin pads

- Shin Pad Sleeves and Wraps — anti-slip compression for a snug fit

- Mini Carbon Guards for Youth Players — lightweight, safe protection

- Limited Edition Gold Carbon Pads — collectible weave aesthetics

FAQs – Everything You Need to Know

What is carbon fiber and why is it used in sports? Carbon fiber is a high-strength, low-weight material used in aerospace, motorsport, and footwear. See ¿Funcionan las plantillas de fibra de carbono? It’s ideal when you need thin, light, and tough protection—exactly what a shin guard demands.

How long do carbon fiber shin guards last? With proper care, multiple seasons. Retire if cracks or foam compression appear.

Are they FIFA-approved? Yes—rounded edges and safe coverage comply with common league requirements.

Can I customize the design or logo? Absolutely. Names, numbers, crests, and team colors are all available.

How to select the right size for kids and adults? Measure tibia length and choose size accordingly (Mini/Small, Midi, or Large).

Join the Movement — Play Your Truth

Follow us on Instagram, TikTok, and YouTube for fit guides, lab tests, and behind-the-scenes footage. Subscribe to our newsletter for early access to new drops and club pricing. Become a VIP tester for next-gen carbon gear — your feedback shapes the future of protection.