Carbon fiber extrusion—including continuous pultrusion, thermoplastic composite extrusion, reactive extrusion, and extrusion-based additive manufacturing—has matured into one of the most advanced manufacturing routes for producing lightweight, high-stiffness, corrosion-resistant structural profiles.

Industries transitioning from aluminum extrusions now demand materials that deliver higher specific strength, near-zero thermal expansion, improved fatigue endurance, and superior dimensional stability. Carbon fiber composite profiles meet this requirement through controlled fiber orientation, engineered resin matrices, optimized fiber volume fraction (FVF), and precision die design.

At the beginning of this article, we briefly note that Chinacarbonfibers is among the composite manufacturers (produttore di composito di carbonio) capable of producing custom carbon fiber extruded tubes, rods, beams, and box sections—but the focus of this guide is not on sales. It is to help engineers, designers, and procurement teams fully understand the science, engineering, processes, and application logic behind carbon fiber extrusion.

1. Understanding Carbon Fiber Extrusion

1.1 What Carbon Fiber Extrusion Really Means

Unlike metal extrusion (where molten metal is pushed through a die), carbon fiber extrusion refers to shaping continuous fiber-reinforced polymer composites using:

- Pultrusion (continuous pulling through a heated die)

- Thermoplastic composite extrusion (fiber + polymer melt)

- Reactive extrusion / frontal polymerization

- Extrusion-based additive manufacturing (3D printing)

Each approach manipulates carbon fibers—typically derived from PAN precursors, pitch-based precursors, and processed through stabilization, carbonization, and graphitization—into high-performance structural profiles.

1.2 Key Composite Entities in Extrusion

Carbon fiber extrusion integrates the following composite science elements:

- Tow / roving / bundles

- Fiber sizing & surface treatment

- Continuous vs. chopped vs. milled carbon fibers

- UD tapes, woven fabrics, bidirectional fabrics

- Resin systems: epoxy, thermoset, thermoplastic (PEEK, PPS, PA, PP)

- Hybrid composites (glass + carbon, nanoparticle-modified resin)

- Fiber volume fraction (FVF) control

- Void content measurement / quality verification

- Material anisotropy (directional properties)

These determine the final mechanical, thermal, and electrical performance of the extruded composite.

When requiring tailored solutions, some engineers rely on fabbrica di compositi personalizzati services to match fiber architecture and resin systems to specific performance targets.

2.1 The Data-Driven Comparison

| Proprietà | Composito in fibra di carbonio | Aluminum 6061-T6 | Vantaggio |

|---|

| Densità | 1.5–1.6 g/cm³ | 2,7 g/cm³ | ~42% lighter |

| Specific Strength | 600–1200 MPa/(g/cm³) | ~115 MPa/(g/cm³) | 5–10× higher |

| Specific Modulus | 70–150 GPa/(g/cm³) | ~26 GPa/(g/cm³) | 3–6× higher |

| CTE (Longitudinal) | –1 to +0.5 µm/m-K | 23.6 µm/m-K | near-zero expansion |

| Corrosione | Inert | Needs anodizing | maintenance-free |

| Fatigue failure | No yield point | Yielding & cracking | much longer life |

2.2 Engineering Benefits Explained

Strength-to-weight ratio Directly tied to continuous fiber alignment and high FVF.

Thermal stability Low coefficient of thermal expansion → stability in:

- precision robotics

- semiconductor equipment

- optical/laser alignment systems

Fatigue endurance CFRP avoids metal fatigue because:

- no dislocation movement

- no yield point

- anisotropic load management

Corrosion resistance Carbon/epoxy systems are inert—crucial for marine & chemical environments.

Vibration damping 5× better damping than aluminum → quieter, more stable systems.

For automotive engineers, see examples in auto in fibra di carbonio.

3. Carbon Fiber Extrusion Technologies

3.1 Continuous Pultrusion (Primary Industrial Method)

Pultrusion is the most widely used continuous carbon fiber extrusion method.

Process summary:

- Fiber creels feed continuous tows

- Fibers pass through resin impregnation (thermoset or reactive resin)

- Composite passes into heated forming die

- Resin polymerizes → B-stage → C-stage

- Continuous profile exits the die and is cut to length

Advantages:

- High axial modulus

- Excellent dimensional repeatability

- Low void content

- Best FVF control

- Ideal for beams, rods, tubes, box sections

Design possibilities:

- Hollow mandrels

- Multi-cavity profiles

- Thin-wall precision sections

- Complex geometries shaped inside multi-zone dies

3.2 Thermoplastic Composite Extrusion

Uses engineering polymers such as:

Can use:

- Continuous fiber

- Short fiber (SCF)

- Milled fiber

Advantages:

- Impact toughness

- Riciclabilità

- Weldability

- Rapid forming

3.3 Reactive Extrusion / Frontal Polymerization

A cutting-edge method where polymer curing occurs via exothermic chain reaction inside the die.

Ideale per:

- Very large hollow tubes

- Variable-thickness profiles

- Low-energy curing systems

- Aerospace R&D programs

4.1 Mechanical Properties

Controlled by:

- Fiber orientation (axial, ±45°, transverse)

- Layer stacking & laminate design

- Resin selection

- Fiber-matrix adhesion (sizing, coupling agents)

Performance includes:

- Resistenza alla trazione

- Modulo

- Compressive strength

- Flexural stiffness

- Shear resistance

- Buckling load capacity

4.2 Thermal & Electrical Characteristics

- Low CTE → stable dimensions

- High thermal stability

- Electrical conductivity (depending on architecture)

- Heat dissipation controlled by fiber alignment

4.3 Composite Defects to Control

Industry key entities:

- Voids / pores

- Fiber misalignment

- Resin-rich zones

- Delaminazione

- Matrix cracking

Process parameters that control defects:

- Resin flow

- Die temperature gradient

- Pulling force stability

- Impregnation pressure

5. Carbon Fiber Extruded Profile Types

5.1 Tubes

- Round tubes

- Multi-cavity tubes

- Telescopic sections

For deeper tube specifications, refer to Carbon Fiber Tube China — Buyers Guide, Prices, Specs, and Suppliers.

5.2 Rods

Unidirectional (UD) rods with maximum axial stiffness.

5.3 Box Sections

- Square

- Rectangular

- Thin-wall box beams

5.4 Custom Shapes

- Angles

- Channels

- I-beams

- Aerofoil sections

Fiber architectures available:

- UD

- Tessuto

- ±45° biax

- Hybrid layups

For fully customized shapes, engineers frequently explore fibra di carbonio personalizzata soluzioni.

6. Applications Across Industries

6.1 Aerospace & UAV

- Drone arms

- Struts

- Airframe components

6.2 Robotics & Automation

- Linear actuator rails

- Gantry beams

- High-speed pick-and-place arms

6.3 Medical & Scientific Equipment

- Imaging systems

- Microscopy frames

- Positioning stages

6.4 Automotive & EV

- Structural brackets

- Lightweight crash structures

- Interior reinforcement tubes

6.5 Energy, Sports & Civil Engineering

- Wind turbine elements

- Componenti per biciclette

- Structural retrofitting profiles

To understand fabrication techniques such as trimming and cutting, see: How to Cut Carbon Fiber Tube.

7. Carbon Fiber Profile Design & Ordering Process

7.1 Step 1: Engineering Consultation

Provide:

- Loads

- Environmental exposure

- Temperature range

- Expected service life

- Deflection limits

7.2 Step 2: Profile Specification

Submit:

- 2D drawings (DXF, DWG)

- 3D models (STEP, IGS)

- Target tolerances

We advise:

- Wall thickness optimization

- Fiber architecture

- Corner radii for manufacturability

7.3 Step 3: Prototype Development

Small batches for:

- Mechanical testing

- Functional trials

- Validation

7.4 Step 4: Production & QA

Typical lead times:

- 3–5 weeks for standard

- 6–8 weeks for complex custom

Quality checks include:

- FVF measurement

- Dimensional accuracy

- Mechanical test coupons

8. Frequently Asked Questions (FAQ)

Q1: Is carbon fiber extrusion more expensive than aluminum? A: Initially, yes. However, the total cost of ownership is often lower when considering performance benefits: reduced energy consumption (lightweighting), zero maintenance (no corrosion), longer lifespan, and system-level savings (smaller actuators, less support structure).

Q2: How do I join or machine carbon fiber profiles? A: They can be machined (drilling, milling) with carbide tools and proper dust extraction. Joining is achieved via adhesive bonding (epoxy, methacrylate) or specialized mechanical fasteners. We provide detailed technical guides.

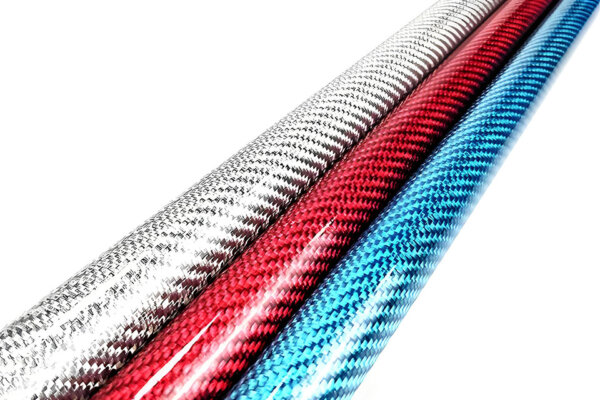

Q3: Can you match a specific color or surface finish? A: Yes. We offer various surface finishes (glossy, textured, painted) and can incorporate colored films or coatings during the extrusion process.

Q4: What are the minimum order quantities (MOQ)? A: For standard profiles, MOQ can be as low as 50 meters. For custom dies and profiles, please contact us for project-specific evaluation.

Q5: Do you provide material certifications? A: Absolutely. We supply full material traceability, batch testing reports, and can comply with industry-specific standards (e.g., aerospace, medical).

9. Work With Chinacarbonfibers (Commercial Section)

While the majority of this article provides purely technical and engineering insight, Chinacarbonfibers offers full-stack composite profile manufacturing:

- Continuous carbon fiber pultrusion

- Thermoplastic composite extrusion

- Reactive extrusion for large hollow structures

- Custom dies and complex multi-cavity profiles

- Engineering consultation & joint design optimization

- QA documentation, FVF, void-content testing

Contattaci E-mail: [email protected] WhatsApp: +86 13626191009