Prepreg koolstofvezel: de sleutel tot een sterk, lichtgewicht product

Waarom uw producten nu prepreg koolstofvezel nodig hebben

Maak je dingen die moeten zijn sterk maar ook licht? Wil je jouw producten kijken beter dan wat anderen maken?

Het probleem is duidelijk. Reguliere materialen zijn te zwaar. Zij pauze te gemakkelijk. Ze zien er niet uit speciaal genoeg voor uw klanten.

Wanneer producten te zwaar zijn, meer kosten verzenden. Auto's gebruiken meer gas. Fietsen bewegen langzamer. Sportuitrusting voelt onhandig.

Dit wordt slechter als je dingen sterker probeert te maken. Meer metaal toevoegen? Nu is het nog zwaarder. Gebruik plastic? Het is licht maar te zwak.

Uw klanten willen betere productenZe willen dingen die licht zoals plastic maar sterk zoals metaal. Ze willen producten die ziet er geweldig uit En langer duren.

De perfecte oplossing: onze prepreg koolstofvezel

Wij maken prepreg koolstofvezel producten. We hebben dit gedaan voor 28+ jaar in China. Wij kunnen maken aangepaste onderdelen speciaal voor jou.

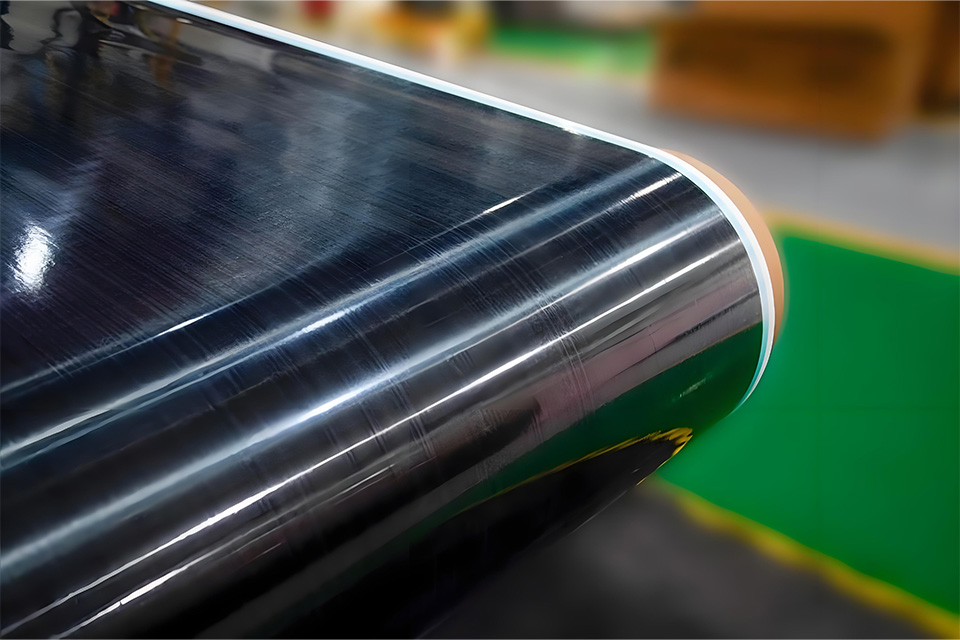

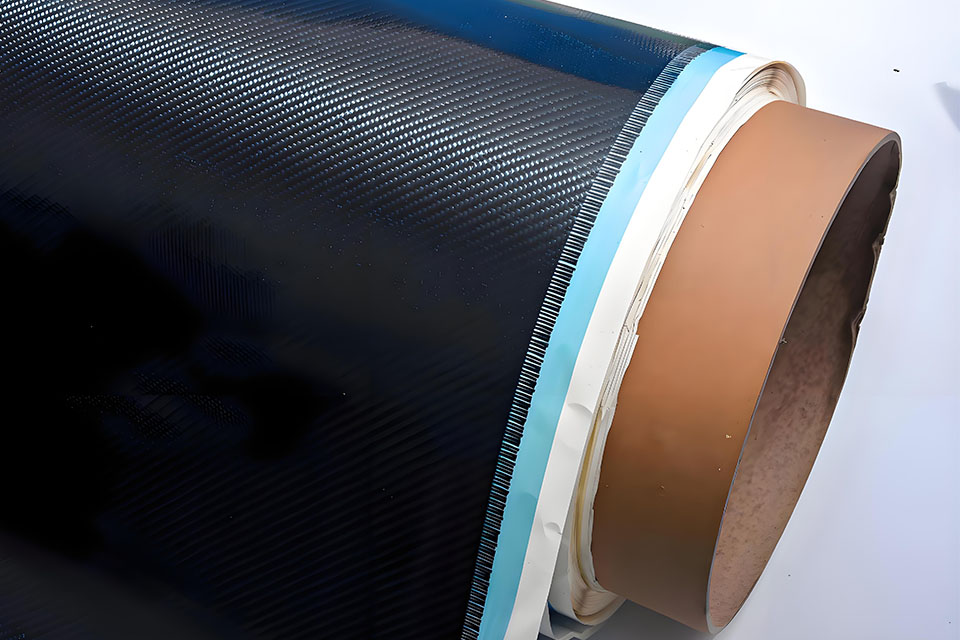

Wat is prepreg koolstofvezel? Het is koolstofvezel met hars al gemengd. Dit maakt het gemakkelijk om te vormen tot elke vorm wat je nodig hebt. De naam “prepreg” betekent “voorgeïmpregneerd” met hars.

Waarom onze Prepreg koolstofvezel zo goed werkt

- Zijn superlicht – veel lichter dan metaal

- Zijn heel sterk – kan sterker zijn dan staal

- Het ziet er geweldig uit – heeft een speciaal patroon waar mensen dol op zijn

- We kunnen het maken in elke vorm je hebt nodig

- Het duurt langer dan andere materialen

De markt groeit snel

Steeds meer bedrijven gebruiken nu prepreg koolstofvezel. De markt zal groeien van $11,45 miljard in 2025 naar $21,86 miljard in 2034.

Waarom? Omdat het lost problemen op dat andere materialen dat niet kunnen.

| Wat mensen willen | Wat gewone materialen doen | Wat onze koolstofvezel doet |

|---|---|---|

| Lichtgewicht | Te zwaar, hogere verzendkosten | 5x lichter dan staal |

| Hoge sterkte | Niet sterk genoeg, breekt gemakkelijk | Sterker dan de meeste metalen |

| Goed uiterlijk | Ziet er saai uit, moet geverfd worden | Natuurlijk patroon ziet er high-end uit |

| Lang Leven | Roest, barst, slijt | Duurt jaren langer |

| Aangepaste vormen | Moeilijk om complexe vormen te maken | Kan maken elke vorm je hebt nodig |

Wie gebruikt onze Prepreg koolstofvezel?

Wij helpen veel soorten bedrijven betere producten:

1. Auto-onderdelen

Autofabrikanten moeten auto's maken lichter om minder gas te gebruiken of meer bereik uit batterijen te halen. Onze koolstofvezel auto-onderdelen hen hierbij helpen.

Het probleem: Metalen auto-onderdelen zijn te zwaar.

Waarom het slecht is: Auto's gebruiken meer gas. Elektrische auto's gaan minder ver.

Onze oplossing: Onze koolstofvezelonderdelen zijn 40% aansteker maar net zo sterk. Wij maken dingen als:

- Motorkappen van koolstofvezel

- Gesmede koolstofvezel Lamborghini-onderdelen die er geweldig uitzien

- Mercedes koolstofvezel spoilers die licht en sterk zijn

- Aangepaste dashboardpanelen

2. Sportuitrusting

Atleten hebben behoefte aan uitrusting die: licht Maar sterk. Gewone materialen werken niet goed genoeg.

Het probleem: Zware sportkleding maakt je langzamer.

Waarom het slecht is: Je verliest races. Je raakt sneller moe.

Onze oplossing: Onze koolstofvezels maken sportuitrusting die je helpt winnen:

- Fietsframes die zijn 60% aansteker

- Tennisrackets die slaan moeilijker

- Golfclubs die zwaaien sneller

- Helmen die beschermen beter

3. Motoronderdelen

Motorrijders willen dat hun motoren er goed uitzien koel en ga snel. Ons koolstofvezel motorfiets onderdelen helpen met beide.

Het probleem: Metalen onderdelen zijn zwaar en zien er niet bijzonder uit.

Waarom het slecht is: Fietsen zijn langzamer. Ze lijken op elke andere fiets.

Onze oplossing: Onze koolstofvezelonderdelen maken motorfietsen beter:

- Kuipdelen die zijn lichter

- Gastanks die meer brandstof bevatten

- Stoelen die eruit zien verbazingwekkend

- Aangepaste onderdelen die niemand anders heeft

4. Medische hulpmiddelen

Artsen hebben hulpmiddelen nodig die: licht, sterk, En veilig.

Het probleem: Metalen medische instrumenten zijn te zwaar voor langdurige operaties.

Waarom het slecht is: Dokters worden moe. Patiënten wachten langer.

Onze oplossingOnze medische hulpmiddelen van koolstofvezel zijn:

- 60% aansteker dan stalen gereedschappen

- Net als sterk

- Veilig te gebruiken bij röntgenfoto's

- Gemakkelijk schoon te maken

Hoe wij uw prepreg koolstofvezel onderdelen maken

We use two main ways to make your parts, depending on performance targets, production volume, and cost requirements.

These processes are part of our prepreg carbon fiber manufacturing capabilities for OEM and custom projects.

1. Hotmeltproces (65% van de markt)

Dit is onze meest gewoon manier. We voegen koolstofvezel en hete hars samen. Dit maakt onderdelen die:

- Meer milieuvriendelijk (minder chemicaliën)

- Sterker als het klaar is

- Beter voor complexe vormen

2. Oplosmiddel-dipproces (30% van de markt)

Soms gebruiken we deze manier. We dopen koolstofvezel in hars met oplosmiddel. Dit werkt goed als je het volgende nodig hebt:

- Lagere kosten onderdelen

- Sneller productie

- Eenvoudiger vormen

Waarom zou u voor ons kiezen voor uw koolstofvezelbehoeften?

Wij zijn niet zomaar een fabriek. Wij hebben 28+ jaar koolstofvezelproducten maken. Dit is waarom u voor ons zou moeten kiezen:

- Aangepast ontwerp: Wij maken aangepaste koolstofvezelonderdelen alleen voor jou

- Volledige service: Wij helpen met ontwerp, het maken van gereedschappen, testen en verzenden

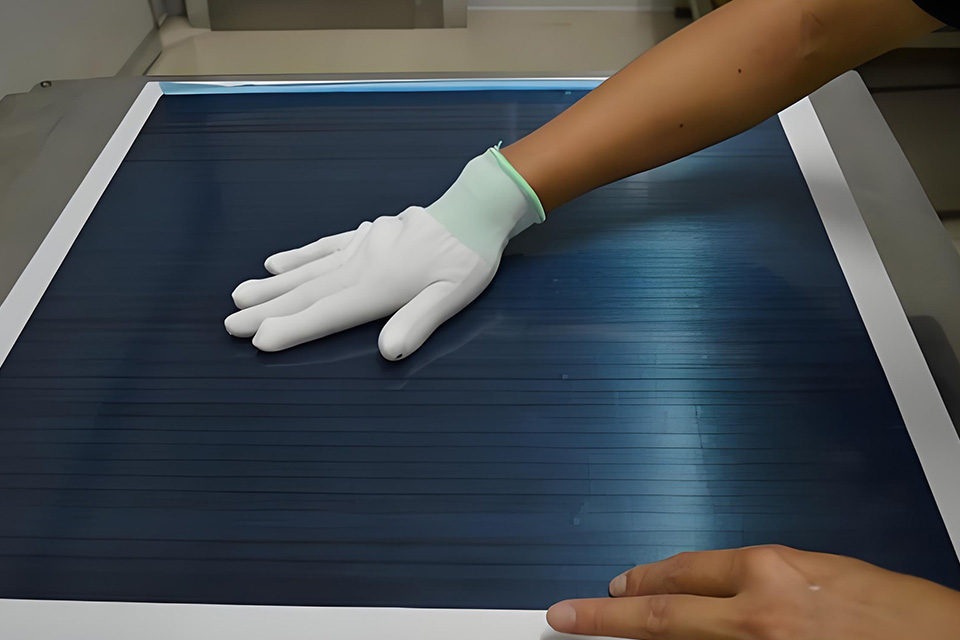

- Hoge kwaliteit:We controleren elk onderdeel om er zeker van te zijn dat het perfect is

- Op tijd: Wij verzenden wanneer we zeggen dat we zullen verzenden

- Eerlijke prijs: Wij geven u goede prijzen omdat wij alles zelf maken

Wat onze klanten zeggen

“We hebben jarenlang metalen onderdelen geprobeerd. Ze waren te zwaar. Jullie koolstofvezelonderdelen bespaarden ons 40% aan gewicht en onze klanten zijn er dol op.” – Auto Parts Company

“Onze sportuitrusting verkoopt veel beter nu we jullie koolstofvezel gebruiken. Het is lichter en sterker dan onze oude materialen.” – Sports Gear Maker

Wereldwijde marktgroei laat zien dat u de juiste keuze maakt

De markt voor koolstofvezels groeit snelHierdoor zien meer bedrijven hoe goed het is.

- Europa: $3,5 miljard markt in 2025, met een jaarlijkse groei van 9,6%

- Azië: Groeit het snelst met 9,6% per jaar

- Noord-Amerika: 28% van de markt in 2024

Verschillende industrieën die koolstofvezel gebruiken

| Industrie | Marktaandeel (2025) | Waarom ze het gebruiken |

|---|---|---|

| Lucht- en ruimtevaart | 40% | Maakt vliegtuigen lichter, zodat ze minder brandstof verbruiken |

| Windenergie | 25% | Maakt grotere windturbinebladen mogelijk |

| Automobiel | 18% | Maakt auto's lichter en sterker |

| Sportuitrusting | 12% | Maakt uitrusting die atleten helpt winnen |

Wat wij voor u kunnen maken

Wij kunnen maken koolstofvezelproducten voor bijna elke behoefte:

- Auto-onderdelen: Motorkappen, spoilers, dashboardpanelen

- Motorfiets onderdelen: Kuipdelen, gastanks, spatborden

- Sportuitrusting: Fietsframes, tennisrackets, golfclubs

- Medische hulpmiddelen: Chirurgische instrumenten, röntgentafels, beugels

- Aangepaste artikelen:Bijna alles wat je maar kunt bedenken

Bent u klaar om uw producten te verbeteren?

De probleem Het is duidelijk: gewone materialen zijn te zwaar, te zwak of zien er niet goed genoeg uit.

Uw klanten voelen de pijn: Ze betalen meer voor verzending. Hun producten gaan kapot. Ze onderscheiden zich niet van anderen.

Ons oplossing is eenvoudig: op maat gemaakte prepreg koolstofvezelonderdelen, speciaal voor u gemaakt door onze fabriek met meer dan 28 jaar ervaring.

Neem vandaag nog contact met ons op en ontdek hoe wij u kunnen helpen bij het maken van uw producten:

- Lichter

- Sterker

- Beter uitziend

- Langduriger

Met onze expertise op het gebied van prepreg koolstofvezels helpen wij u graag bij het oplossen van uw materiaalproblemen.