Вы хотите, чтобы ваши самолеты летать дальше? Вам нужны детали, которые продлится дольше? Металлические балки делают ваш самолет слишком тяжелый?

Старые металлические детали делают самолеты тяжелыми. Тяжелым самолетам нужно больше топлива. Больше топлива стоит больше денег. Металлические детали также могут ржаветь и ломаться.

Ваши самолеты должны быть свет но сильный. Это трудно сделать со старыми материалами.

Почему это вредит вашему бизнесу

Если ваши самолеты слишком тяжелые:

- Вы тратите слишком много на топливо

- Ваши самолеты не могут летать так, как далеко

- Детали должны быть отремонтированы чаще

- Вы отстаете от других компаний лучшие самолеты

Каждый день, когда вы продолжаете использовать тяжелые металлические детали, вы теряете деньги. Ваши самолеты остаются на земле дольше. Ваши клиенты выбирают другие компании.

Ответ: наши С-образные балки из углеродного волокна

Мы делаем С-образные балки из углеродного волокна которые решают все эти проблемы! Наши балки сделаны специально для вас – обычай подходит для ваших самолетов.

Балки из углеродного волокна являются 39% сильнее чем старые балки, но гораздо легче. Это означает, что ваши самолеты могут:

- Летать дальше на том же топливе

- Нести более люди или вещи

- Нуждаться меньше фиксация

- Оставайтесь в воздухе дольше

Что делает наши С-образные балки из углеродного волокна особенными

Посмотрите, что показывают наши тесты:

| Что мы тестируем | Что мы нашли |

|---|

| Сила | До 39% прочнее старых балок |

| Масса | 60% легче металлических деталей |

| Как долго они длятся? | в 3-5 раз длиннее металла |

| Время делать | Всего 2,5-3 часа на часть |

| Качество | Менее 1% дефектов |

Как мы делаем их лучше

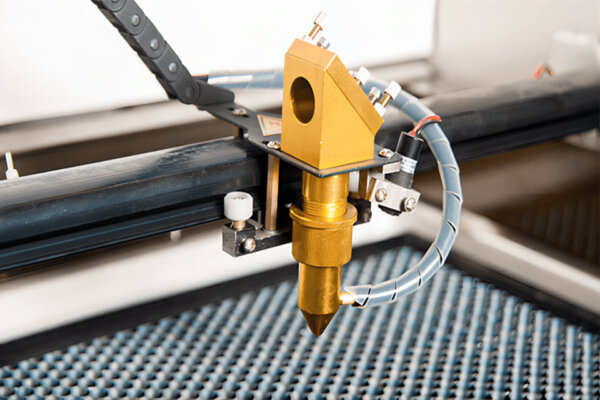

Наш С-образная балка из углеродного волокна шаги выполнения:

- Мы используем вершина волокно (например, карбон T700 волокно)

- Мы располагаем волокна в правильном порядке для большей прочности

- Мы используем специальный клей, который не образует пузырьков воздуха.

- Мы нагреваем и прессуем как надо

- Мы проверяем каждый луч перед отправкой

Кто использует наши C-образные балки

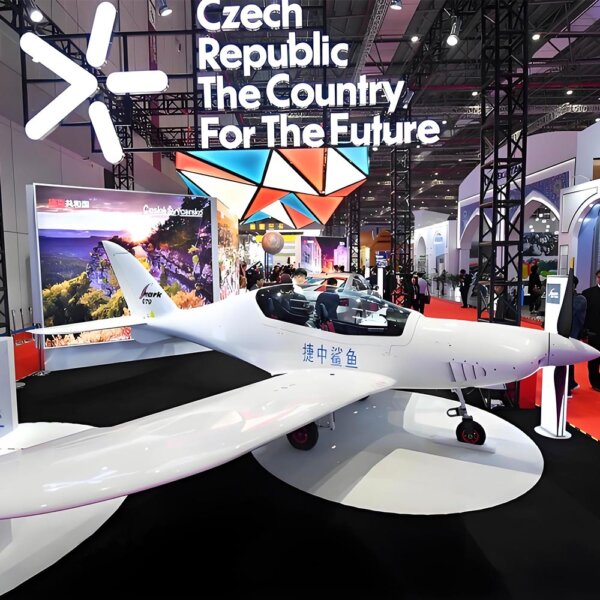

Наши балки работают во многих плоскостях:

- Большие самолеты которые летают люди

- Самолет с поворотным винтом которые поднимаются как вертолет, но летают как самолет

- Маленькие самолеты которые должны быть легкими

- Дроны это должно лететь долго

Почему стоит выбрать нашу компанию?

Мы не просто фабрика. Мы делаем изготовленное на заказ углеродное волокно в течение многих лет.

Мы даем вам:

- OEM/ODM-сервис – мы делаем то, что ВАМ нужно

- Быстрое изготовление – 2,5-3 часа на часть

- Идеально подходит – сделано специально для ваших самолетов

- Высшее качество – менее 1% дефектов

- Лучше других – наша технология волоконного рулевого управления делает балки 19-39% прочнее

Как наши детали помогают вашему бизнесу

При покупке наших С-образных балок из углеродного волокна:

- Ваши самолеты используют меньше топлива (экономьте деньги)

- Ваши самолеты могут летать дальше (сделать клиентов счастливыми)

- Ваши детали прослужат долго дольше (за вычетом затрат на ремонт)

- Ваши самолеты могут перевозить более (заработать больше денег)

- Ваша компания выглядит более высокотехнологичный (победить других)

Что еще мы производим

Мы не просто производим С-образные балки. Мы также производим:

Как сделать у нас заказ

Приобрести наши С-образные балки из углеродного волокна просто:

- Расскажите нам что тебе нужно

- Мы составить план и покажу вам

- Вы говорите да

- Мы делать ваши части

- Мы тест каждая часть

- Мы отправлять их вам быстро

Послушайте счастливых создателей самолетов

«Мы сократили потребление топлива на 15% после установки этих С-образных балок». – Big Plane Company

«Наши самолеты теперь летают на 2 часа дольше на том же топливе». – Small Plane Maker

«Детали подходят с первого раза. Больше не нужно ждать исправлений». — Drone Builder

Наука, лежащая в основе нашего углеродного волокна

Наше углеродное волокно не похоже на другие. Мы используем:

- Управление по оптоволокну что делает балки 19-39% прочнее

- Специальный клей который делает детали, которые не ломаются

- Умные машины которые наилучшим образом размещают волокна

- Нагреть и нажать в самый раз, чтобы делать идеальные детали

Начните летать лучше сегодня

Не позволяйте тяжелым металлическим деталям удерживать ваши самолеты на земле. Не тратьте больше денег на топливо. Не отставайте от других производителей самолетов.

Позвоните нам сегодня чтобы обсудить ваши потребности. Мы изготовим идеальные С-образные балки из углеродного волокна для ваших самолетов.

Посетите наш главная страница углеродного волокна чтобы увидеть все, что мы можем сделать для вас!

Теги: Самолет Электрификация, Энергоэффективность, Снижение выбросов углекислого газа, Композитные материалы, Усиление конструкций, Легкие авиационные компоненты, Самолеты eVTOL, Водородные топливные элементы, Аэрокосмическая техника, Композиты из углеродного волокна