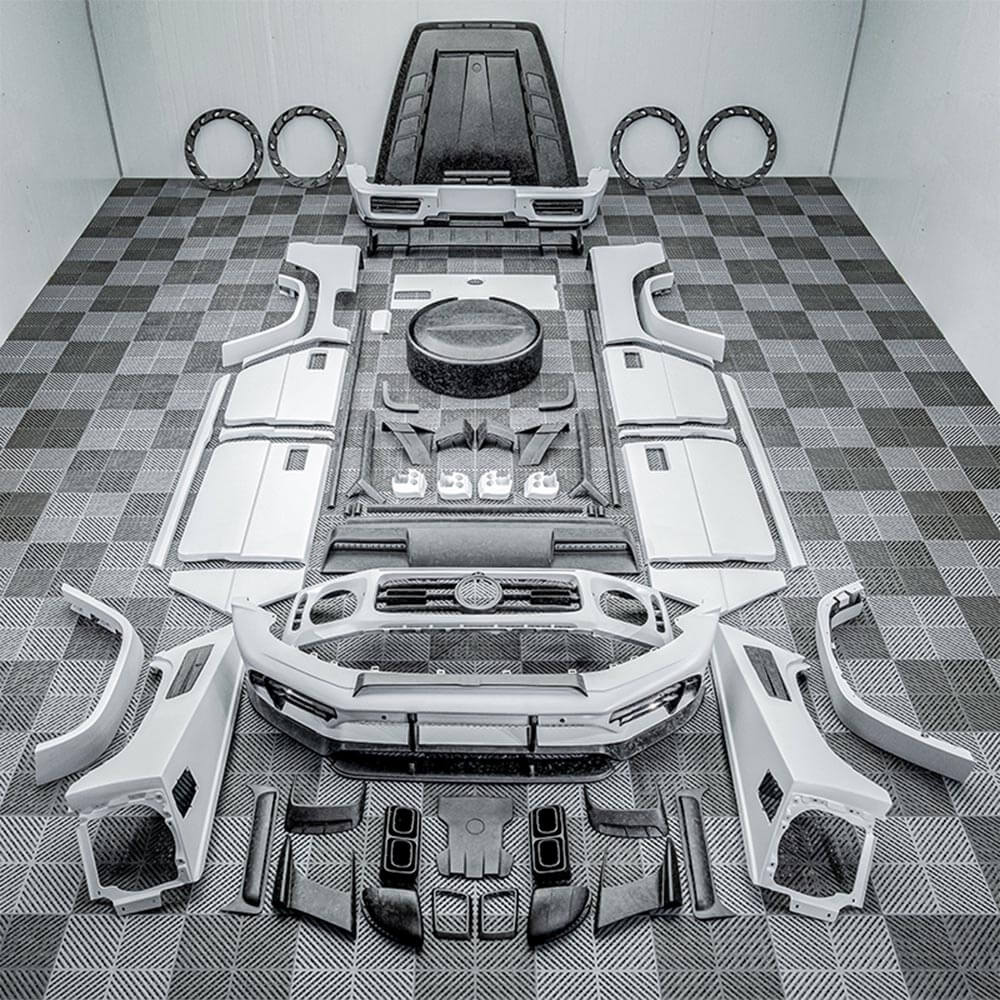

Премиальный кованый стартовый набор из углеродного волокна для высококлассных деталей на заказ

Добро пожаловать в мир кованое углеродное волокно! Наш стартовый набор поможет вам сделать удивительные детали для автомобилей, самолетов, спортивного снаряжения и многого другого. Мы являемся одним из лучших изготовленное на заказ углеродное волокно завод по производству продукции Компания, которая на протяжении многих лет производит лучшие детали из карбона.

Почему вы выбрали именно наш набор?

- Легко использовать - даже если вы новичок в работе с углепластиком

- Материалы высшего качества - такой же, как в автомобилях класса люкс

- Полная поддержка - Наша команда помогает вам на каждом шагу

- Пользовательские параметры - изготавливать детали, которые точно соответствуют вашим потребностям

- Быстрая доставка - начните прямо сейчас

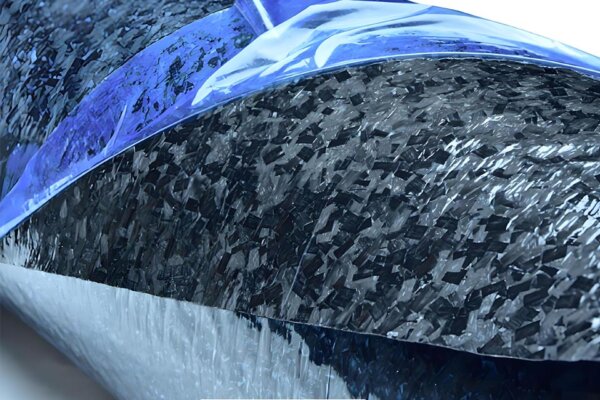

Что такое кованое углеродное волокно и почему оно удивительно

Кованое углеродное волокно - это новый способ для изготовления деталей из углерода. В ней используется измельчённый углерод смешанный с смола для изготовления прочных, хорошо выглядящих деталей. В отличие от старых плетение из углеродного волокнаКованый карбон имеет холодный мраморный вид, который нравится многим.

The кованые углерод волокно процесс начинается с рубленые углеродные волокна которые смешиваются с эпоксидная смола. Затем мы используем тепло и давление для изготовления конечной детали. Благодаря этому детали получаются очень прочными, но при этом отлично выглядят. Наши клиенты в аэрокосмическая промышленность, автомобильный, и спортивный инвентарь Очень нравится, что кованые карбоновые детали одновременно легкие и прочные. Случайный узор из измельченные волокна Придает каждому изделию неповторимый вид, который выделяет его на фоне других.

Полный комплект для создания кованых изделий из углеродного волокна

Наш стартовый набор есть все необходимое, чтобы начать делать кованые детали из углеродного волокна. Каждый комплект включает:

| Элемент | Количество | Цель |

|---|

| Карбоновый буксир | 500g | Основной материал волокна |

| Эпоксидная смола премиум-класса | 1L | Связующее вещество |

| Отвердитель | 500 мл | Активирует смолу |

| Воск для освобождения | 100g | Для легкого извлечения деталей |

| Компрессионная форма (образец) | 1 | Для придания формы деталям |

| Руководство по эксплуатации | 1 | Пошаговое руководство |

| Защитные перчатки | 2 пары | Защита |

| Контейнеры для смешивания | 5 | Для приготовления смолы |

The Набор для создания кованых изделий из углеродного волокна предназначен как для начинающих пользователей, так и для профессионалов. Наш система эпоксидных смол это тот же самый, который мы используем на нашей фабрике для высокопроизводительный части.

"Этот набор изменил наш подход к изготовлению деталей для прототипов. Качество потрясающее, а команда поддержки помогала нам на каждом шагу". - Джон М., инженер-конструктор автомобильной промышленности

Как сделать удивительные изделия из углеродного волокна

Изготовление кованые детали из углеродного волокна легко с нашим набором. Вот как:

- Смешайте смолу - Соедините эпоксидная смола и отвердитель справа соотношение смол

- Подготовьте углерод - Получите свой измельчённый углерод готовый

- Комбинируйте материалы - Смешайте волокно и смола вместе

- Заполните форму - Поместите смесь в пресс-формы

- Надавите – Сжать материал для удаления воздуха

- Излечивать - Дайте ему затвердеть, следуя нашему руководству

- Заканчивать - Снимите и отполируйте готовый кованый карбон часть Вы можете использовать наш набор с 3D-печатная форма или наш двухкомпонентная пресс-форма из металла. Оба варианта отлично подходят для изготовления твёрдый углерод части. Советы для достижения наилучших результатов:

- Всегда используйте аэрозольный разделительный воск в ваших формах

- Следуйте точно система смол инструкции по смешиванию

- Прикладывайте равномерное давление, когда использование компрессии техника

- Отшлифуйте и отполируйте для кованый глянец заканчивать

Технические характеристики наших кованых углеродистых материалов

Наш настоящее углеродное волокно материалы обеспечивают отличные механические характеристики для всех видов проектов:

- Прочность на разрыв: 3500 МПа

- Плотность: 1,6 г/см³

- Термостойкость: До 180°C

- Содержание смолы: 40% по весу

- Длина волокна: 25 мм измельчённое полотенце

- Время затвердевания: 24 часа при комнатной температуре или 4 часа при 80°C. детали из углеродного волокна в нашем наборе вырезаны по идеальному размеру для удобства укладка и наилучшую прочность. Наш литьё смолы система работает как с компрессионная формовка твердых материалов методы и смола печатная части.

Отрасли, которым нравится наше кованое углеродное волокно

Наш Изделия из углеродного волокна используются во многих ведущих отраслях промышленности:

- Автомобили и мотоциклы

- Детали приборной панели

- Кузовные панели

- Внутренняя отделка

- Аэрокосмическая промышленность

- Компоненты кабины

- Неструктурные части

- Нестандартные светильники

- Спортивное оборудование

- Головки для клюшек для гольфа

- Велосипедные компоненты

- Запчасти для теннисных ракеток

- Медицинское оборудование

- Корпуса для оборудования для получения изображений

- Компоненты протезов

- Легкие приспособления для передвижения

- Бытовая электроника

- Чехлы для телефонов

- Чехлы для ноутбуков

- Корпуса динамиков

The процесс формовки Мы используем детали, которые отлично выглядят и хорошо работают. Когда нити углерода сжимаются вместе с правой количество смолыОни делают детали, которые лучше, чем обычные. ламинат карбон.

Почему стоит выбрать кованое углеродное волокно вместо традиционных методов

| Особенность | Кованый карбон | Традиционное плетение | Однонаправленный |

|---|

| Смотреть | Мраморный узор | Обычное плетение | Прямые линии |

| Сила | Очень высокий | Высокий | Самый высокий в одном направлении |

| Простота использования | Самый простой | Середина | Самое сложное |

| Отходы | Очень низкий | Середина | Высокий |

| Кривые | Отличный | Ограниченный | Ограниченный |

| Расходы | Середина | Высокий | Самый высокий |

Когда ты купить кованое углеродное волокно У нас вы получите материалы, с которыми легко работать. В отличие от однонаправленный углерод или препрег Наши кованые карбоновые изделия лучше поддаются обработке при создании сложных форм.

Наш CT12 рубленый Система из углеродного волокна может быть помещённый в форму практически любой формы. Это делает его идеальным для изготовления сложных деталей, которые было бы трудно сделать с помощью обычных плетение из углеродного волокна.

Преимущества нашей технологии кованого углерода:

- Меньше отходов по сравнению с традиционными методами

- Ускоренное время производства

- Лучше для сложных форм

- Каждая деталь имеет уникальный вид

- Сильнее в нескольких направлениях

Мы используем то же самое ковка Мы используем те же технологии, что и производители автомобилей класса люкс, но заставляем их работать на ваши проекты. Наш сайт композитные материалы проверены на соответствие самым высоким стандартам.

Истории успеха клиентов

Наш детали из углеродного волокна помогли многим предприятиям:

"Мы перешли на кованый карбон для наших мотоциклетных деталей, и продажи выросли на 30%. Клиентам нравится уникальный внешний вид". - Майк Т., магазин мотоциклов Custom Motorcycle Shop

"Аэрокосмические детали, которые мы изготавливаем с помощью этой системы, прошли все наши испытания. Экономия веса просто потрясающая". - Сара Л., поставщик аэрокосмической продукции

Наша линия спортивного оборудования получила огромный толчок к развитию, когда мы добавили кованое углеродное волокно варианты". - Дэвид К., производитель спортивного оборудования

Когда вы работаете с нашими кованые детали из углеродного волокнаВы присоединяетесь к компаниям, которые ценят качество и инновации. Наш Смола для покрытия XCR Придает деталям отделку, которая сохраняется в течение многих лет.

Как заказать индивидуальные решения из углеродного волокна

Готовы начать создавать удивительные кованые детали из углеродного волокна? Вот как сделать заказ:

- Свяжитесь с нашей командой - Расскажите нам о своем проекте

- Получить индивидуальное предложение - Мы создадим пакет, который будет соответствовать вашим потребностям

- Получите свой набор – Быстрая доставка по всему миру

- Начните создавать - При нашей полной поддержке

Для крупных проектов мы предлагаем полный изготовленное на заказ углеродное волокно продукт производство. Наш завод может изготавливать детали от маленьких до очень больших, используя наши передовые технологии. пресс-формы и команда экспертов.

Варианты заказа:

- Стартовые наборы для тестирования и обучения

- Создание индивидуальных пресс-форм

- Полный цикл производства

- Только материальные упаковки

- Обучение и поддержка

Не ждите, пока производить углерод детали, которые поразят ваших клиентов. Наш Набор для создания кованых изделий из углеродного волокна это первый шаг к созданию деталей, которые выделяются на фоне других. Свяжитесь с нами сегодня, чтобы присоединиться к революции углеродного волокна!

Резюме: Наши кованые углеродные сплавы премиум-класса Стартовый набор из оптоволокна предоставляет вам все необходимое для создания потрясающих карбоновых деталей профессионального уровня. Благодаря мраморному внешнему виду, высочайшей прочности и нашей экспертной поддержке вы в кратчайшие сроки создадите потрясающие детали для автомобильной, аэрокосмической и других отраслей промышленности.