عملية صب المواد المركبة من ألياف الكربون بالضغط الساخن

يعتمد مصنعنا على عملية الضغط الساخن المتقدمة لألياف الكربون مع قالب فولاذي P20، مما يضمن الكفاءة العالية والدقة والمتانة والفعالية من حيث التكلفة لإنتاج عالي الجودة.

هل أنت يكره هل تشعر أن دراجتك ياماها R1 ثقيلة جدًا؟ الأجزاء البلاستيكية الأصلية تُضيف وزنًا زائدًا. هذا يُبطئك على المسار ويجعل دراجتك تبدو كأي دراجة أخرى.

يواجه العديد من مالكي R1 هذه المشكلة مشاكل كبيرة:

دراجة ثقيلة تعني سرعات أبطأ و سوء التعاملكل رطل إضافي يُصعّب عليكَ تحريك دراجتك. وعندما تتحطم، تنكسر تلك الأجزاء البلاستيكية بسرعة.

الوزن الإضافي الناتج عن أغطية المخزون يجعل سيارتك R1 أبطأ في:

بالإضافة إلى ذلك، تبدو دراجتك كأي دراجة أخرى في سباقات الدراجات. لقد أنفقت مبلغًا كبيرًا على دراجتك R1. ألا ينبغي أن تكون مميزة؟

تصل أغطية R1 إلى 40% أثقل من ألياف الكربون. هذا الوزن الزائد يؤثر سلبًا على أداء دراجتك وقدرتها على المناورة.

نحن نصنع عالية الجودة هياكل مصنوعة من ألياف الكربون من أجل سيارتك ياماها R1. قطع غيارنا تصنع دراجتك:

باعتبارنا شركة مصنعة لألياف الكربون، فإننا نقدم مخصص و تصنيع المعدات الأصلية/تصنيع التصميم الشخصي خدمة لجميع قطع غيار R1. نستخدم قطع غيار أصلية ألياف الكربون PrePreg مع طلاء الأشعة فوق البنفسجية للأجزاء التي تدوم لسنوات.

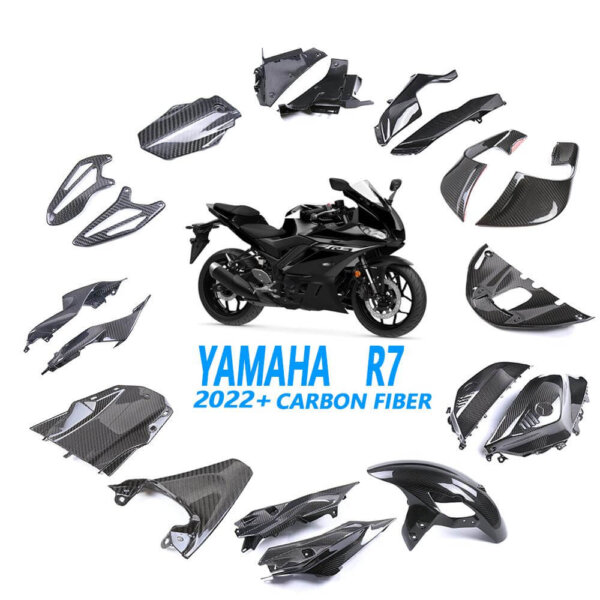

نحن نصنع قطع ألياف الكربون لجميع سيارات ياماها موديلات R1 من عام 2004 إلى عام 2024. يمكنك تصفح مجموعتنا الكاملة من أغطية ألياف الكربون Yamaha R1 لرؤية كافة الخيارات.

جميع أجزائنا تأتي مع طلاء واقي من الأشعة فوق البنفسجية التي تتوقف عن البهتان لمدة 5 سنوات على الأقل.

| جزء | توفير الوزن | نطاق السعر | تثبيت |

|---|---|---|---|

| أغطية جانبية | ولاعة 30-40% | اتصل للحصول على السعر | سهل – 30 دقيقة |

| التغطية الأمامية | ولاعة 35% | اتصل للحصول على السعر | متوسط – ساعة واحدة |

| قسم الذيل | ولاعة 30% | اتصل للحصول على السعر | سهل – 45 دقيقة |

| مجموعة كاملة | ولاعة 30-40% | اتصل للحصول على السعر | يوصى بالتثبيت الاحترافي |

أجزائنا الأكثر شعبية أغطية ألياف الكربون لدراجة ياماها R1 موديل 2016 الألواح الجانبية وأجزاء الذيل. تُعطي هذه أكبر تغيير في المظهر مقابل السعر.

يختار الدراجون أجزاءنا لأربعة أسباب رئيسية:

قطع ألياف الكربون لدينا تُناسب تمامًا قطعك الأصلية. لا حاجة لقطع أو أدوات خاصة!

تبيع العديد من المتاجر أغطيةً مزيفةً "بمظهر الكربون". هذه مجرد بلاستيك بنقشة كربونية. قطع غيارنا حقيقي ألياف الكربون المصنوعة من هذه الخطوات:

الكربون المزيف مجرد بلاستيك، لا يُخفّض الوزن ولا يُضيف قوة. تأكد من حصولك على ألياف كربون حقيقية مثل منتجاتنا!

هل تريد شيئًا لا يملكه أحد غيرك؟ نحن نقدم لك ألياف الكربون المخصصة خيارات:

قم بزيارة موقعنا ألياف الكربون المخصصة الصفحة لرؤية ما يمكننا أن نصنعه لك فقط.

نصنع قطع غيار لجميع سنوات R1. لكل سنة قوالبها الخاصة لضمان التوافق المثالي:

كل قطعة مصممة لتناسب تمامًا القطعة الأصلية. لا حاجة للحفر أو القطع!

نحن لا نصنع قطع غيار الدراجات فحسب، بل أيضًا ألياف الكربون صانع، ونحن نصنع أيضا:

هل أنت مستعد لجعل هاتفك R1 أخف وزنًا وأكثر جمالًا؟ اطلبه بسهولة:

نشحن إلى جميع أنحاء العالم مع خدمة تتبع كاملة. تصل القطع في صناديق متينة لمنع التلف.

دراجتي R1 موديل 2020 فقدت 8 أرطال فقط مع تغيير غطاءات جانبية وقسم خلفي! أصبحت الدراجة أسرع بكثير الآن. - مايك س.

مُناسب تمامًا لسيارتي R1 موديل 2016. استغرق تبديل جميع القطع حوالي ساعة. يبدو رائعًا! - جون ت.

الكربون الحقيقي يبدو أجمل بكثير من أغطية الكربون المزيفة التي اشتراها صديقي. يستحق كل قرش. - سارة ر.

توقف عن ركوب سيارة R1 ثقيلة وعادية المظهر. مع أغطية من ألياف الكربونستحصل على

قم بزيارة موقعنا أغطية ألياف الكربون لدراجة ياماها R1 افتح الصفحة الآن للاطلاع على جميع الخيارات. سيارة أحلامك R1 على بُعد نقرات قليلة!

يعتمد مصنعنا على عملية الضغط الساخن المتقدمة لألياف الكربون مع قالب فولاذي P20، مما يضمن الكفاءة العالية والدقة والمتانة والفعالية من حيث التكلفة لإنتاج عالي الجودة.

يُشغّل مصنعنا أكثر من 100 جهاز ضغط ساخن، باستخدام قوالب ألومنيوم وتقنية الحث الفراغي لتشكيل ألياف الكربون بدقة. تُعزز الحرارة والضغط العاليان المتانة والثبات والجودة المثالية.

يعمل مركز أبحاث ألياف الكربون لدينا على تعزيز الابتكار في مجال الطاقة الجديدة والذكاء والتصميم خفيف الوزن، باستخدام المواد المركبة المتقدمة وألياف Krauss Maffei لإنشاء حلول متطورة تركز على العملاء.

فيما يلي إجابات للأسئلة الشائعة من مصنع منتجات ألياف الكربون ذي الخبرة

نحن ننتج مجموعة واسعة من مكونات ألياف الكربون، بما في ذلك أجزاء السيارات، وأجزاء الدراجات النارية، ومكونات الفضاء، والاكسسوارات البحرية، والمعدات الرياضية، والتطبيقات الصناعية.

نحن نستخدم بشكل أساسي ألياف الكربون عالية الجودة والمقواة مسبقًا والمركبات عالية الأداء المقواة بألياف الكربون ذات السحب الكبير لضمان القوة والمتانة وخصائص الوزن الخفيف.

نعم، منتجاتنا مطلية بطبقات واقية من الأشعة فوق البنفسجية لضمان المتانة طويلة الأمد والحفاظ على مظهرها المصقول.

نعم، منشآتنا ومعداتنا قادرة على إنتاج مكونات ألياف الكربون كبيرة الحجم مع الحفاظ على الدقة والجودة.

ما هي فوائد استخدام منتجات ألياف الكربون؟

توفر ألياف الكربون نسبة استثنائية من القوة إلى الوزن، ومقاومة للتآكل، وصلابة، واستقرار حراري، ومظهر عصري أنيق.

نحن نقدم خدماتنا لقطاعات السيارات والدراجات النارية والفضاء والبحرية والطبية والرياضة والصناعية مع التركيز على مكونات ألياف الكربون خفيفة الوزن وعالية الأداء.

نعم، نحن نوفر ألياف الكربون المخصصة حلول مصممة خصيصًا وفقًا لمواصفاتك، بما في ذلك التصميمات والأحجام والأنماط الفريدة.

نحن نستخدم تقنيات متقدمة مثل صب الأوتوكلاف، والضغط الساخن، والتعبئة المفرغة من الهواء، لضمان الدقة والاستقرار والجودة في كل منتج. مع العجائب التي يقدمها موضوع Hello Elementor، نحاول التأكد من أنه يعمل بشكل رائع مع جميع الموضوعات الرئيسية أيضًا.

نحن نستخدم قوالب الألومنيوم والفولاذ P20، المصممة للمتانة والدقة العالية، لإنشاء مكونات ألياف الكربون المعقدة والدقيقة.

تخضع منتجاتنا لفحوصات مراقبة الجودة الصارمة، بما في ذلك دقة الأبعاد، وسلامة المواد، واختبار الأداء، لتلبية معايير الصناعة.