Echtes Carbon Fiber Nummernschild Rahmen für Autos und Motorräder mit 4-Loch

Inhaltsverzeichnis

Echtes Carbon Fiber Nummernschild Rahmen für Autos und Motorräder mit 4 Löchern

Machen Sie Ihre Auto oder Motorrad besser aussehen mit unserem Nummernschildrahmen aus echter Kohlefaser. Das Platte wird nur für Sie von unseren Spitzenkräften Herstellung von Kohlenstofffaserprodukten Team. Die beenden ist glatt und glänzend. Es wird fit beliebig Fahrzeug und es cool aussehen lassen. Unser Nummernschildrahmen Sind hochwertig und für die Ewigkeit gemacht.

Ich habe das Nummernschildrahmen aus Kohlefaser auf meinem BMW. Es sieht so gut aus! Die Leute bleiben stehen, um ihn anzuschauen." - Mike, zufriedener Kunde

Warum sollten Sie sich für unseren echten Carbonfaser-Kennzeichenrahmen entscheiden?

- Leicht aber sehr stark

- Schlankes Design das auf jedem Auto gut aussieht

- Einfache Installation mit allen Montagezubehör inklusive

- Schützen dein Platte vor Schaden

- UV Mantel um Sonnenschäden vorzubeugen

- Passt auf alle Standard Nummernschildrahmen

Premium-Carbonfaserprodukte für Ihr Fahrzeug

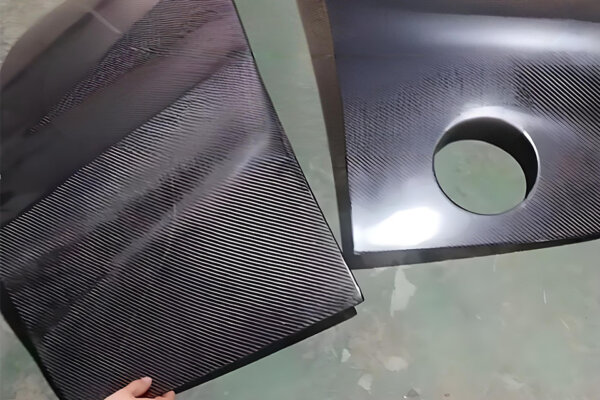

Unser Nummernschildrahmen aus Kohlefaser wird aus echten Kohlefaser. Es ist keine Fälschung. Sie können das Echte sehen weben Muster. Die Website Oberfläche ist glatt mit einer Glanz beenden. Das Produkt wird gemacht, um verbessern. dein Auto oder Motorrad.

Wir verwenden ein spezielles Beschichtung damit der Rahmen lange hält. Er verblasst nicht in der Sonne. Unser Kohlefaserplatte macht Ihr Fahrzeug besser aussehen und zeigen, dass Ihnen etwas an der Detail.

Der 4 Löcher Design macht es einfach, auf jedes Auto zu montieren. Sie erhalten alle Schrauben, die Sie benötigen. Es dauert nur fünf Minuten, um Upgrade das Aussehen Ihres Fahrzeugs.

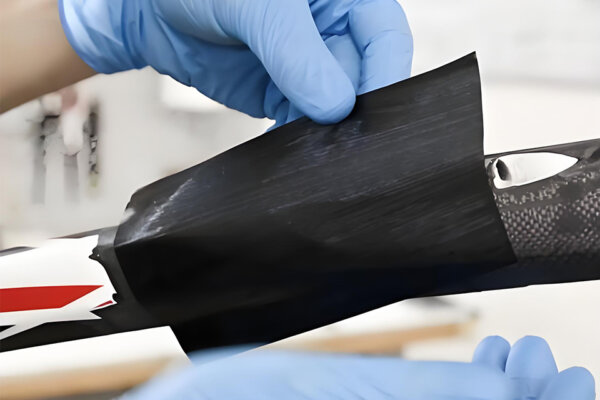

Herstellungsprozess unserer Kohlefaserprodukte

Unser Herstellung Team verwendet die besten Material um jeden Nummernschildrahmen. Wir beginnen mit realen Kohlefaser Verbundwerkstoff. Dann formen wir es zu fit Ihr Auto perfekt.

Der Produktion Prozess umfasst viele Schritte:

- Schneiden Sie die Kohlefaser Blätter

- Sie in speziellen Formen formen

- Erhitzen Sie sie, um sie stark zu machen

- Polieren jeden Rahmen von Hand

- Hinzufügen UV Schutz Mantel

- Prüfen Sie jede Detail zweimal

- Sorgfältig verpacken

Diese sorgfältige Konstruktion ist der Grund, warum unser Kohlefaserprodukte halten so lange. Wir kümmern uns um Qualität bei jedem Schritt.

Technische Spezifikationen

| Besonderheit | Spezifikation |

|---|---|

| Material | Echte Kohlefaser |

| Beenden | Hoch Glanz |

| Löcher | 4 Löcher Standardmuster |

| Gewicht | 0,3 Pfund (sehr leicht) |

| Größe | Passt auf alle US-Standardplatten |

| UV-Schutz | Ja, speziell UV Mantel |

| Installation | Einfache Installationinklusive aller Hardware |

| Haltbarkeit | Extrem temperaturbeständig |

Kundenrezensionen zu unserem Carbonfaser-Kennzeichenrahmen

Unsere Kunden lieben es, dass ihre Autos mit unserer Kohlefaser aussehen Nummernschildrahmen. Hier ist, was sie sagen:

"Dieser Rahmen hat meine Motorrad so aussehen sportlich. Der Kohlefaser sieht echt aus, weil es echt ist." - James T.

"Ich wollte personalisieren meine Auto und dieser Rahmen war perfekt. Die beenden ist erstaunlich und es passt super." - Sarah K.

"Der Qualität ist erstklassig. Ich habe schon billige Rahmen gehabt, aber diese echte Kohlefaser ist man in einer anderen Liga." - Robert M.

Warum sich unsere Marke abhebt

Als führender Marke In Kohlefaserproduktekonzentrieren wir uns auf die Herstellung der besten Nummernschildrahmen möglich. Unser Herstellung Prozess ist etwas Besonderes. Wir machen keine Abstriche.

Sie können eine subtil Logo oder einen Namen für Ihren Rahmen, wenn Sie möchten. Dies macht Ihr Auto wirklich Ihnen. Sagen Sie uns einfach bei der Bestellung, was Sie wollen. Unser Komponente Tests zeigen, dass unsere Rahmen fünfmal länger halten als normale Kunststoffrahmen. Deshalb wählen Autoliebhaber unsere echte Kohlefaser Rahmen.

Perfekte Passform für jedes Fahrzeug

Ob Sie einen Luxus Auto, Motorrad, oder täglich Fahrzeug, unser Nummernschildrahmen aus Kohlefaser Wille fit perfekt. Die Design passt zu jedem Stil.

Der Kohlefaser weben Das Muster sieht toll aus:

- Sportwagen

- Luxus-Limousinen

- BMW und andere Premiummarken

- Motorrad Nummernschilder

- SUVs und Lastwagen

- Klassische Autos

Wenn Sie unsere Nummernschildrahmen aus Kohlefaser, dein Fahrzeug bekommt einen sofortigen Stil Upgrade. Es ist eine kleine Veränderung, die einen großen Unterschied macht.

Bestellen Sie Ihren Carbonfaser-Kennzeichenrahmen noch heute

Lassen Sie nicht zu, dass Ihr Auto oder Motorrad schlicht aussehen. Holen Sie sich Ihr Nummernschildrahmen aus echter Kohlefaser jetzt. Es ist ein einfacher Weg, um Ihre Fahrzeug besser aussehen.

Unser Kohlefaserprodukte sind für Menschen gemacht, denen das Aussehen ihres Autos wichtig ist. Schließen Sie sich Tausenden von zufriedenen Kunden an, die sich bereits für unsere hochwertig Rahmen.

Kontaktieren Sie uns noch heute, um Ihre Bestellung aufzugeben!

Telefon/Whatsapp: +86 136 2619 1009

E-Mail: [email protected]

Website: www.chinacarbonfibers.com

Auto aus Kohlefaser | Kohlefaser-Motorrad | Kundenspezifische Kohlefaser | Kohlefaser | Carbonfaser-Kennzeichenrahmen

Zusammenfassung: Unsere echten Kohlefaser-Kennzeichenrahmen werten das Aussehen Ihres Fahrzeugs mit echter Kohlefaserkonstruktion, perfekter Passform und UV-Schutz sofort auf. Diese leichten und dennoch langlebigen Premium-Rahmen enthalten alle Montageteile für eine einfache Installation an jedem Auto oder Motorrad.

Heißpressformverfahren für Kohlefaserverbundwerkstoffe

Unsere Fabrik verwendet ein fortschrittliches Heißpressverfahren für Kohlefasern mit einer P20-Stahlform, wodurch eine hohe Effizienz, Präzision, Haltbarkeit und Kosteneffizienz für eine qualitativ hochwertige Produktion gewährleistet wird.

Kohlefaser-Autoklav

Unser Werk verfügt über mehr als 100 Heißdruckautoklaven. Mit Aluminiumformen und Vakuuminduktion formen wir Carbonfasern präzise. Hohe Hitze und hoher Druck sorgen für Festigkeit, Stabilität und einwandfreie Qualität.

Forschungszentrum für Kohlenstofffaser-Technik

Unser Carbonfaser-Forschungszentrum treibt Innovationen in den Bereichen neue Energie, Intelligenz und Leichtbau voran und nutzt fortschrittliche Verbundwerkstoffe und Krauss Maffei FiberForm, um hochmoderne, kundenorientierte Lösungen zu schaffen.

Häufig gestellte Fragen

Hier finden Sie die Antworten auf die häufig gestellten Fragen der erfahrenen Fabrik für Kohlefaserprodukte

Wir produzieren eine breite Palette von Kohlefaserkomponenten, darunter Autoteile, Motorradteile, Luft- und Raumfahrtkomponenten, Schiffszubehör, Sportgeräte und Industrieanwendungen.

Wir verwenden hauptsächlich hochwertige Prepreg-Kohlefasern und mit Kohlefasern verstärkte Hochleistungsverbundwerkstoffe, um Festigkeit, Haltbarkeit und geringes Gewicht zu gewährleisten.

Ja, unsere Produkte sind mit UV-Schutzlacken beschichtet, um eine lange Haltbarkeit zu gewährleisten und ihr poliertes Aussehen zu bewahren.

Ja, unsere Anlagen und Geräte sind in der Lage, große Kohlefaserkomponenten unter Beibehaltung von Präzision und Qualität herzustellen.

Welche Vorteile bietet die Verwendung von Kohlefaserprodukten?

Kohlefaser bietet ein außergewöhnliches Verhältnis von Festigkeit zu Gewicht, Korrosionsbeständigkeit, Steifigkeit, thermische Stabilität und ein elegantes, modernes Erscheinungsbild.

Wir beliefern die Automobil-, Motorrad-, Luft- und Raumfahrt-, Schifffahrts-, Medizin-, Sport- und Industriebranchen mit einem Schwerpunkt auf leichten und leistungsstarken Kohlefaserkomponenten.

Ja, wir bieten individuelle Carbonfaserlösungen, die auf Ihre Spezifikationen zugeschnitten sind, einschließlich einzigartiger Designs, Größen und Muster.

Wir nutzen fortschrittliche Technologien wie Autoklavformen, Heißpressen und Vakuumverpackung, um Präzision, Stabilität und Qualität in jedem Produkt zu gewährleisten. Wunder mit dem Hello Elementor Theme, wir versuchen sicherzustellen, dass es auch mit allen wichtigen Themes gut funktioniert.

Wir verwenden auf Langlebigkeit und hohe Genauigkeit ausgelegte Formen aus Aluminium und P20-Stahl, um komplexe und präzise Kohlefaserkomponenten herzustellen.

Unsere Produkte werden strengen Qualitätskontrollen unterzogen, darunter Maßgenauigkeit, Materialintegrität und Leistungstests, um den Industriestandards zu entsprechen.