Unser Kohlefaserschaft ist der beste Weg, um Ihre Queue spielen besser. Als Top-Carbonfaser Produktfertigungsanlagestellen wir hochwertige Kohlefaser-Queues für Spieler, die mehr gewinnen wollen. Unser Schächte sind stark, leicht und helfen Ihnen, den Ball jedes Mal genau richtig zu treffen.

Warum wählen Sie unser Queue-Schäfte aus Kohlefaser?

- Viel stärker als Holzschäfte

- Verformt sich nicht und verändert sich nicht durch Hitze

- Helfen Sie, mehr Schüsse zu treffen

- Langlebig für viele Jahre

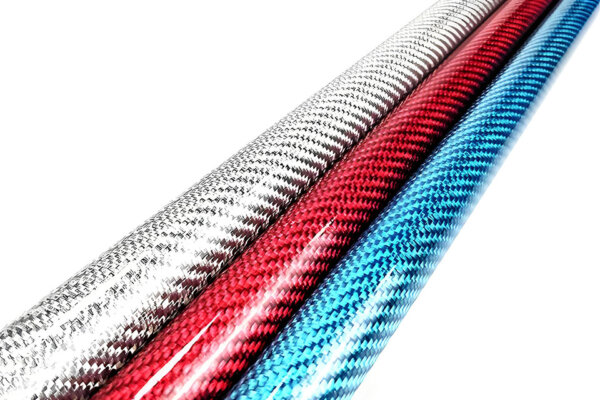

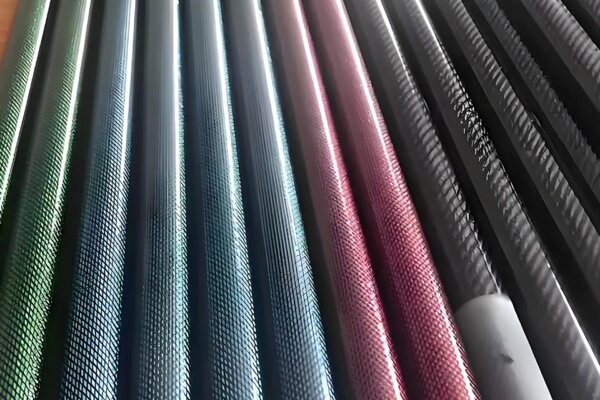

- Sieht sehr schön aus

Wir machen Kohlefaser Teile für viele große Marken in Automobile und Motorräder, Luft- und Raumfahrt, Sportgeräte, neue Energien, medizinische Geräte, Gebäudedekorationen, Unterhaltungselektronik, Schiffbau und Industrieausrüstung. Jetzt bringen wir die gleiche Spitzenqualität zu Ihrem Billardqueue.

Modernste 11,8-mm-Kohlefaser-Schafttechnologie

Unser 11,8mm Schaft verwendet die besten Kohlefasertechnologie auf der Welt. Die Welle ist mit multidirektionalem Fasern, die es super stark machen, aber immer noch gut fühlen, wenn Sie spielen. Die Carbonkonstruktion Unserer Spielwelle gibt Ihnen bessere Gefühl und Feedback als alt Holzschäfte. Mit unserem Kohlefaserschafterhalten Sie weniger Ablenkung wenn Sie die Spielball. Das bedeutet, dass mehr Schüsse abgegeben werden!

Die wichtigsten Merkmale unseres 11,8-mm-Kohlefaserschafts:

| Besonderheit | Nutzen |

|---|

| Multidirektionale Kohlefaserfilamente schaffen Stärke | Kein Verziehen, bleibt immer gerade |

| Geringe Durchbiegung Design | Präzisere Schüsse, weniger Fehlschüsse |

| Perfekt 11.8 mm Größe der Spitze | Großartig für alle Arten von Aufnahmen |

| Gewölbeplatte Bewehrung | Zusätzliche Haltbarkeit an Belastungspunkten |

| Kohlefaser-Material mit zeitgemäßem Design | Sieht toll aus, spielt sich noch besser |

"Seit ich das hier habe Kohlefaser-Profi-Schaftist mein Spiel um zwei Stufen gestiegen. Die Spielballkontrolle ist erstaunlich!" - Tom, Berufsspieler

Professioneller 12.4mm Carbon Fiber Pro Shaft für Power Spieler

Wenn Sie Ihr Spiel etwas kräftiger gestalten möchten, ist unser 12,4 mm Profi-Welle ist genau richtig. Diese Kohlefaser-Profi Modell bietet Ihnen die perfekte Mischung aus Leistung und Genauigkeit. Hergestellt mit Kohlefaser in Luft- und Raumfahrtqualität, Die 12.4 mm Spitze ist perfekt für Spieler, die einen stärkeren Schlag wünschen. Der Profikegel Design hilft Ihnen, jeden Schuss mit weniger Anstrengung zu kontrollieren. Diese Kohlefaser-Profi-Schaft wird von vielen führenden Billardspieler in großen Spielen. Das Besondere an unserer 12,4 mm Welle:

- 15k Kohlefaser Konstruktion für höchste Festigkeit

- Perfekt Profikegel für Handkomfort

- Besonders Aderendhülse die länger hält als normale

- Geringer Wartungsaufwand braucht - einfach sauber wischen

- Funktioniert mit allen Standard Billardqueue Gelenke Unser Kohlefaserverbundwerkstoff Design bedeutet, dass dieser Schaft auch nach tausenden von Spielen seine Form nicht verändert. Die Unterarm aus gebeiztem Ahorn sieht toll aus und bietet die perfekte Gewichtsverteilung für ernsthafte Spieler.

Spezialisierter 10,5-mm-Schaft für Präzisionstechnik

Für Spieler, die eine besonders präzise Kontrolle benötigen, bieten wir eine dünne 10,5 mm neue Welle mit Billardqueue-Schäfte aus Kohlefaser Technologie. Dieser dünne Schaft hilft Ihnen, Schläge zu machen, die andere Queues nicht bewältigen können.

Der Kohlefaserverbundwerkstoffe die wir verwenden, stammen aus demselben Bestand, den wir an Luft- und Raumfahrt Unternehmen. Das bedeutet, dass Ihr Stichwort erhält die gleiche Qualität, die Flugzeuge in der Luft hält! Das dünne Design und die Carbonschaft Kern machen dies perfekt für Sprungbefehl oder Pausenzeichen zu verwenden.

Technische Daten unserer 10,5 mm Präzisionswelle:

| Spezifikation | Detail |

|---|

| Durchmesser | 10,5 mm Tipp |

| Kernmaterial | Polyurethan-Schaumkern |

| Äußere Schicht | 15k Kohlefaser |

| Konstruktion | Dual-Core mit Mikrokomprimierung |

| Beenden | Perlenessenz Beschichtung |

| Gewicht | 3,5 Unzen (superleicht) |

Der schwarzer Schaft mit Geschütztes Metall Akzente sieht erstaunlich aus und wird Ihnen helfen Erhöhen Sie Ihr Spiel zu neuen Höhen. Dieses Modell umfasst unser spezielles Frontend Design, das Ihnen das Beste bietet präziser Hub möglich.

Unsere Kohlefaserschäfte bieten:

- Kein Verziehen wie bei Holzschäfte

- Besser zielen mit geringe Durchbiegung

- Wirbelsäule und Uniform getroffen jedes Mal

- Das beste Gefühl in der Billardwelt

- Eine Möglichkeit, Ihr Spiel auf die nächste Stufe Als ein führender Hersteller in Kohlefasertechnologiesetzen wir unser gesamtes Know-how aus Billardtechnik und Leistung in diese Schächte. Jede Welleneigenschaften das Beste in Verbundbauweise und wird getestet, um sicherzustellen, dass es unseren hohen Standards entspricht.

Warum sollten Sie sich für unsere Carbonfaser-Queue-Produkte entscheiden?

Unser Kohlefaser manufacturing plant has been making high-quality composite parts for many years. We understand how to work with Kohlefaser-Schlepptau und andere fortschrittliche Materialien, um Produkte zu schaffen, die mehr leisten als herkömmliche Optionen.

Wenn Sie eine Queue oder Schaft aus Kohlefaser von uns profitieren Sie von unserer Erfahrung in vielen Bereichen:

- Kraftfahrzeuge und Motorräder Carbonteile, die leicht, aber stabil sein müssen

- Luft- und Raumfahrt Komponenten, die strenge Sicherheitsstandards erfüllen müssen

- Sportausrüstung die den Sportlern einen Vorteil verschafft

- Medizinische Ausrüstung die Leben retten

- Unterhaltungselektronik die dauerhaft sein müssen

- Industrielle Ausrüstung das unter schwierigen Bedingungen funktioniert

Das bedeutet, dass Ihr Queue spielen erhält die gleiche Sorgfalt und Qualität wie Teile, die in Sportwagen und Flugzeugen verbaut werden!

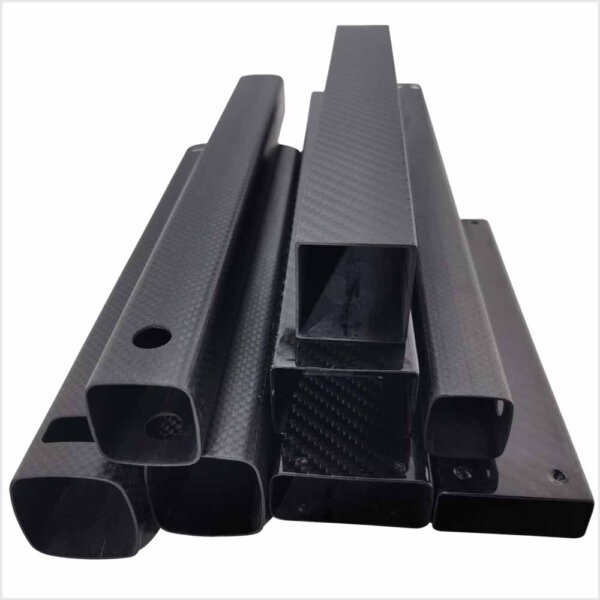

Kundenspezifische Optionen verfügbar:

- Verschiedene Spitzendurchmesser (von 10,5 mm Zu 12,9 mm)

- Gelenktypen passend zu Ihrem vorhandenen Queue

- Benutzerdefinierte Grafiken oder Farben

- Besonders Aderendhülse Materialien

- Team- oder Personal Branding

Unsere Mindestbestellmenge beträgt nur 50 Stück, was uns perfekt macht für Billard Geschäften, Teams oder Händlern, die Spitzenqualität anbieten wollen Kohlenstoff Faserwelle Produkte für ihre Kunden.

Wie unsere Kohlefaserschäfte hergestellt werden

Die Herstellung einer perfekten Kohlefaser-Queue erfordert Geschick und sorgfältige Arbeit. So machen wir es:

- Wählen Sie nur perfekte Kohlefaserqualität Materialien

- Schneiden und schichten Sie die Kohlefaser in unserem Reinraum

- Sie werden in spezielle Formen gelegt, die die genaue Kegel

- Durch Hitze und Druck wird die Verbundwerkstoff

- Maschine auf perfekte Maße (wie 11,8mm Schaft)

- Fügen Sie die Aderendhülse und veredeln mit unseren Spezialbeschichtungen

- Prüfung jeder Welle auf Geradheit und Leistung

- Sorgfältig verpacken für den weltweiten Versand Dieses Verfahren stellt sicher, dass jedes Welleneigenschaften perfekte Ausrichtung und Konsistenz.

Der Stichwort Angeberei Leistung, die Holz einfach nicht bieten kann.

Kundenrezensionen zu unseren Carbonfaserschäften

Unser Kohlefaser Produkte wurden von Spielern auf allen Ebenen gelobt. Hier ist, was sie sagen:

"Mein neues Carbonschaft hat mein Spiel völlig verändert. Schüsse, die ich früher nicht getroffen habe, sind jetzt einfach. Die Spielballkontrolle ist erstaunlich!" - Mike, Turnierspieler

"Ich habe alle großen Marken ausprobiert. Kohlefaser-Profi Wellen, und diese hier ist genauso gut, kostet aber weniger. Mein ganzes Team benutzt sie jetzt." - Sarah, Mannschaftskapitän

"Als Billard Ladenbesitzer, kann ich sagen, dass dies der beste Wert in Billardqueue-Schäfte aus Kohlefaser. Meine Kunden lieben sie und kommen immer wieder gerne zurück. - Bob, Ladenbesitzer

"Der 12,5 mm Der Schaft ist perfekt für meinen Spielstil. Stark, gerade, und sieht auch noch toll aus!" - James, Wochenend-Liga-Spieler

Bestellen Sie Ihre individuellen Carbonfaserschäfte noch heute

Wenn Sie Ihren Kunden das Allerbeste bieten wollen Kohlefaser-Queue Technologie ist es nun an der Zeit, Ihre Bestellung aufzugeben. Unser Kohlefaserschaft Produkte verschaffen Ihrem Unternehmen einen Vorteil im Wettbewerb Billard Markt.

Bestellvorgang:

- Kontaktieren Sie uns mit Ihren Spezifikationen

- Sie erhalten ein Angebot innerhalb von 24 Stunden

- Geben Sie Ihre Bestellung auf (mindestens 10 Stück)

- Genehmigen Sie die von uns zugesandte Probe

- Beginn der Vollproduktion

- Sie erhalten Ihre Sendung in 15-30 Tagen Unser Queue-Angebote die beste Leistung zu wettbewerbsfähigen Preisen. Und weil wir ein direkter Hersteller sind, erhalten Sie Einsparungen direkt vom Hersteller ohne Zwischenhändler.

Wenden Sie sich jetzt an uns, um Ihr Unternehmen mit den besten verfügbaren Kohlefaserschäften aufzuwerten!

Zusammenfassung

Unsere Prämie Kohlefaserschäfte verschaffen Poolbillardspielern mit ihrem starken, verzugsfreien Design und ihrer erstaunlichen Ballkontrolle einen großen Vorteil. Hergestellt von denselben Experten, die auch Teile für die Luft- und Raumfahrt und Sportwagen herstellen, helfen diese Schäfte Ihnen, mehr Stöße zu machen und dabei gut auszusehen. Machen Sie sich bereit, mehr Spiele zu gewinnen!