So reparieren Sie Risse in Kohlefasern: Eine Schritt-für-Schritt-Anleitung

Das Problem: Risse in der Kohlefaser können Ihren Tag ruinieren

Kohlefaser ist sehr starkAber es kann brechenWenn es ein Riss, es ist nicht gut.

Sie sehen eine Riss in Ihrem KohlefaserteilEs sieht schlechtSie denken vielleicht, Sie müssten kaufen ein neues. Ein neues Kohlefaserteil kostet viel Geld. Einige Teile kosten $500 bis $5000 oder mehr!

Der Riss bekommt größer wenn Sie nicht Fix es. Dann Ihre Teil könnte brechen den ganzen Weg. Das ist schlecht für:

- Dein Autoteile

- Dein Fahrradrahmen

- Dein Motorradteile

- Dein Sportausrüstung

Das Problem wird schlimmer: Was passiert, wenn Sie Risse nicht reparieren?

Wann Risse bleiben, mehr schlechte Dinge passieren:

- Der Riss bekommt größer

- Der Teil bekommt schwächer (bis zu 50% schwächer!)

- Wasser kommt rein

- Es sieht hässlich

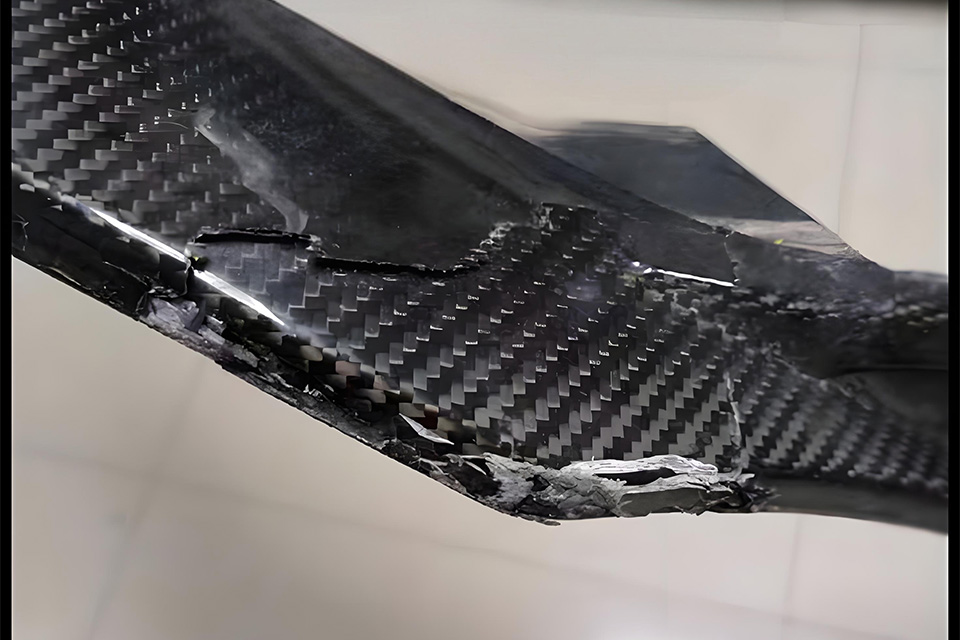

- Es könnte brechen wenn Sie es verwenden

Wasser macht die Riss schlimmer. Die Carbonfaserschichten beginnen zu auseinander kommenDies nennt man Delaminationsschäden.

Manche Leute versuchen Fix es die Falscher WegSie verwenden die falsches ZeugDies macht die Problem schlechter.

Die Lösung: So reparieren Sie Risse in Carbonfasern richtig

Wir haben 28+ Jahre Herstellung KohlefaserprodukteWir wissen, wie man Risse reparieren Die richtiger Weg.

Du kannst Fix am meisten Kohlefaserrisse zu Hause. Oder Sie können uns um Hilfe bitten. Wir machen benutzerdefinierte Kohlefaser Teile, die stark Und gut aussehen.

Was Sie zum Reparieren von Carbonfaserrissen benötigen

Werkzeuge Sie benötigen:

- Nassschleifpapier (120er Körnung bis 2000er Körnung)

- Epoxidharz (mit Härter)

- Schweres Carbonfasergewebe

- Reinigungsalkohol reinigen

- Polierwachs für das Ende

All diese Dinge kosten etwa $50-$200. Das ist viel weniger als ein Neuteil!

Schritt 1: Überprüfen Sie den Riss

Nicht alle Risse sind gleich. Schau dir das an Tisch:

| Risstyp | Wie es aussieht | Wie schwer zu beheben |

|---|---|---|

| Riss im Klarlack | Nur oben, glänzender Teil | Einfach (2-4 Stunden) |

| Matrixriss | Im schwarzen Teil keine Fasern gebrochen | Medium (4-24 Stunden) |

| Strukturriss | Fasern sind gebrochen, Teil verbiegt sich | Hart (24-72 Stunden) |

Schauen Sie sich Ihre Riss. Wenn Sie sehen gebrochene Fasern, es ist ein schlechter Riss. Sie benötigen möglicherweise helfen aus Experten wie wir.

Schritt 2: Reinigen und Vorbereiten

Sauber ist sehr wichtig! Wenn Sie dies überspringen, Fix Wille scheitern (53% der Korrekturen schlagen aufgrund mangelhafter Reinigung fehl).

- Waschen der Teil mit Seife Und Wasser

- Trocken es gut

- Wischen mit Reinigungsalkohol

- Lass es trocken wieder

Jetzt Sand rund um die Riss:

- Verwenden Nassschleifpapier mit 120er Körnung

- STOPPEN wenn Sie sehen schwarzer Staub (das bedeutet, Sie treffen den Kohlenstoff)

- Sand in einem Kreis rund um die Riss

- Machen Sie den Bereich ein wenig rauh also die Epoxid dürfen Stock

Schritt 3: Reparieren Sie den Riss

Nun zum Hauptfix:

Für kleine Risse (nur Klarlack):

- Mischen dein Epoxidharz

- Setzen A dünne Schicht auf der Riss

- Lass es trocken

- Hinzufügen mehr Schichten (insgesamt 2-3)

- Lass es trocken vollständig (überprüfen Sie die Epoxid Feld für die Zeit)

Für größere Risse (mit gebrochenen Fasern):

- Schneiden ein Stück Kohlefasergewebe größer als die Riss

- Mischen dein Epoxidharz

- Setzen Die Tuch auf der zurück der Riss

- Einweichen es mit Epoxid

- Drücken aus irgendwelchen Luftblasen

- Lass es trocken für mindestens 24 Stunden

Schritt 4: Schleifen und Polieren

Nach dem Epoxid Ist hart, du musst es schaffen hübsch:

- Nasser Sand mit 400er Körnung

- Dann 600er Körnung

- Dann 1000er Körnung

- Dann 1500er Körnung

- Dann 2000er Körnung

- Polieren mit Autowachs

Jetzt Ihre Kohlefaserteil sollte aussehen Gut wieder!

Warum unsere Carbonfaserprodukte besser sind

Wir tun nicht nur Kohlefaser reparieren. Wir machen es! Als Hersteller von Kohlefasern mit 28+ Jahre von Erfahrung, wir wissen, wie man:

- Machen Kohlefaser Teile, die weniger anfällig für Risse

- Verwenden Sie die beste Materialien (wie Kevlar Teile für stark beanspruchte Bereiche)

- Erstellen perfekte Carbon-Webmuster

- Anwenden UV-beständiger Klarlack das hält länger

Unser Auto aus Kohlefaser Teile und Motorrad aus Kohlefaser Teile werden hergestellt, um länger halten Und besser aussehen.

Erfolgsraten verschiedener Carbonfaserreparaturen

Schauen Sie, wie gut jeder Fix Werke:

| Verfahren | Kraft zurück | Kosten | Wer macht es? |

|---|---|---|---|

| Nur Harzfüllung | 82% | Niedrig ($) | Du zu Hause |

| Carbonfaser-Patch | 95% | Mittel ($$) | Sie mit gutem Werkzeug |

| Professionelle Reparatur | 98% | Hoch ($$$) | Fachgeschäft |

| Neues OEM-Teil von uns | 100% | Mittel-Hoch ($$-$$$) | Wir machen es für Sie |

Wenn wir eine neues Teil für dich ist es so stark wie Die OriginalWenn Sie Fix A Riss, es ist niemals ganz wie stark.

Häufige Fehler bei der Reparatur von Carbonfasern

Die Leute machen diese Fehler wenn sie versuchen, Kohlefaser reparieren:

- Nicht reinigen der Bereich (53% von schlägt fehl)

- Mithilfe der falsche Materialien (37% der Fehler)

- Zu tiefes Schleifen in die Kohlenstoffschichten (43% der Fehler)

- Nicht zulassen, dass die Epoxidhärtung lang genug (18% der Fehler)

- Verwenden zu viel Harz (macht es 28% schwerer)

Wir machen diese nicht Fehler wenn wir Ihre benutzerdefinierte Kohlefaser Teile.

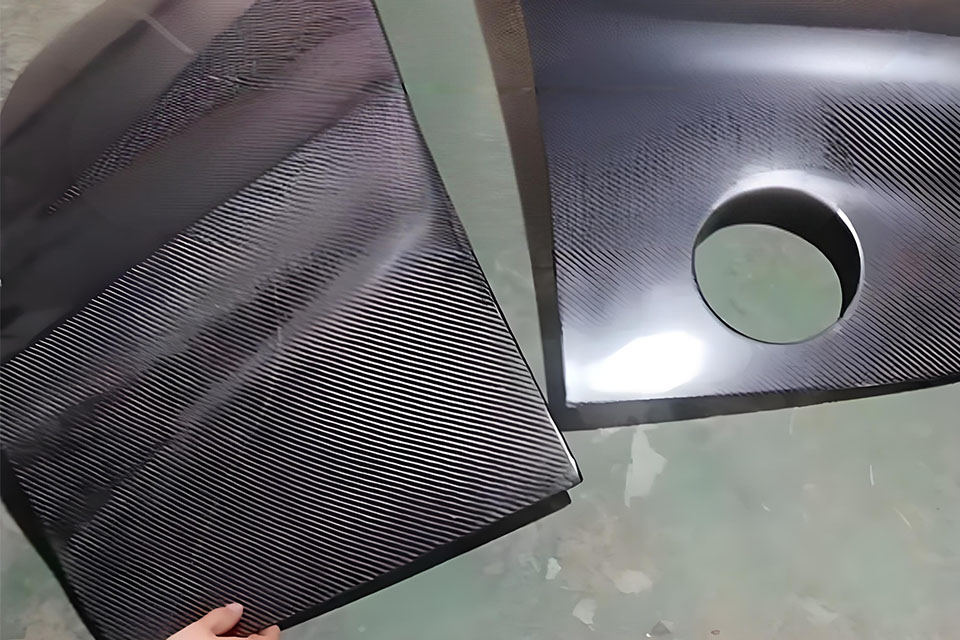

Echte Fälle: Vorher und Nachher

Fall 1: Riss in der Motorhaube aus Kohlefaser

A Kunde hatte eine Riss in ihrem Motorhaube aus KohlefaserSie versuchten, Fix es aber machte es schlechter. Dann kamen sie zu uns.

Vor: Groß Riss mit Ecken und Kanten Nach: Sieht aus wie neu, Festigkeitstest bestanden

Fall 2: Fahrradrahmen aus Kohlefaser

A Rennrad hatte eine kleiner Riss im rahmenDer Eigentümer nutzte Fiberglas Zu Fix es (falsch!). Es pleite in zwei Wochen nochmal.

Wir haben eine neues Teil mit bessere Kohlefaser. Es ist gewesen stark seit 3 Jahren.

Warum Sie uns wählen sollten, anstatt es selbst zu reparieren

Wenn Sie Fix A Riss, das Teil ist niemals als Gut als neu. Hier ist der Grund, warum unsere Neuteile Sind besser:

- Wir verwenden Vakuumverpackung für keine Luftblasen

- Unser Kohlefaser Ist Luft- und Raumfahrtqualität

- Wir testen jedes Teil auf Stärke

- Unser Klarlack hat UV-Schutz

- Wir passen die Carbon-Webmuster perfekt

- Wir geben eine Garantie

Als Hersteller von Kohlefasern In China mit 28+ Jahre Erfahrung, wir machen die besten Teile.

Kundenspezifische Kohlefaserteile, die wir für Sie herstellen können

Wir können machen jedes Kohlefaserteil Sie benötigen:

- Autoteile: Motorhauben, Spoiler, Frontlippen

- Motorradteile: Verkleidungen, Kotflügel, Tanks

- Sportausrüstung: Fahrradrahmen, Hockeyschläger

- Marine-Kohlefaser: Bootsteile

- Verbundwerkstoffe für die Luft- und Raumfahrt: Drohnenteile

- Maßanfertigungen: Bring deine Idee mit!

Alle unsere Teile verwenden die beste Kohlefaser Und moderne Techniken.

Fazit: Reparieren oder ersetzen?

Du kannst kleine Risse reparieren In Kohlefaser selbst. Aber für große Probleme oder wichtige Teile, es ist besser um eine neues Teil von einem guter Hersteller.

Wir haben 28+ Jahre Herstellung KohlefaserprodukteWir wissen, wie man Teile herstellt, die länger halten Und besser aussehen.

Besuchen Sie unsere Kohlefaser Website, um zu sehen, was wir für Sie tun können!