Warum Ihre Ducati einen Carbon-Hinterradkotflügel braucht

Fährst du ein Ducati Panigale V4S? Siehst du Schlamm und Schmutz auf dem Fahrrad nach Fahrten? Das ist ein großes Problem.

Ihr serienmäßiger Kunststoff-Hinterradkotflügel ist nicht gut genug. Es ist schwerEs sieht langweiligEs kann brechen leicht.

Dies macht Ihre schönes Fahrrad sehen schlecht. Schmutz gelangt auf Ihre teurer AuspuffWasserspritzer auf Ihre schöne Kleidung.

Denken Sie darüber nach, wie Ihr Freunde sehen dein Fahrrad. Zeigt es Ihre echter Stil?

Wir machen die am besten Kohlefaser-Heckschützer die all diese Probleme beheben!

Unsere Carbonfaser-Hinterradkotflügel-Lösung

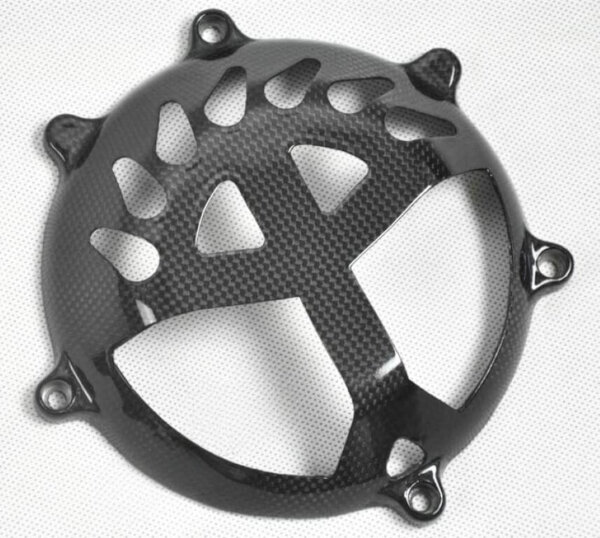

Unser Ducati Panigale V4S Carbonfaser-Hinterradabdeckung matt ist die perfekte Lösung. Es ist:

- 70% Feuerzeug als serienmäßige Kunststoffteile

- Stärker als Fabrikteile

- Besser aussehen mit echtem Carbonfasergewebe

- Perfekte Passform für alle V4S-Modelle (2018-2024)

- Einfach zu installieren – kein Spezialwerkzeug erforderlich

Warum Carbonfaser am besten für Ihre Ducati ist

Carbonfaser ist nicht nur für AussehenEs hat echte Vorteile:

- Weniger Gewicht: Macht Ihr Fahrrad Schneller Und besser handhaben

- Mehr Kraft: Wird nicht brechen oder Riss wie Plastik

- Besserer Schutz: Hält Dreck Und Wasser vom Fahrrad

- Rennsport-Look: Dasselbe Material wie Profi-Rennfahrer

- Lange Lebensdauer: Wird nicht verblassen oder verschleißen wie Plastik

Was unsere Carbonfaser so besonders macht

Wir verwenden nur die besten Materialien:

| Unsere Materialien | Ihre Vorteile |

|---|

| 200 g/m² Leinwandbindung Carbon | Passt perfekt zum Ducati OEM-Look |

| UV-Keramikbeschichtung | Schützt jahrelang vor Sonnenschäden |

| Option für mattes Finish | Rennsportinspirierter Look, der auffällt |

| 100% Carbon-Konstruktion | Kein billiger Glasfaserspachtel |

| Verstärkte Befestigungspunkte | Wird beim Einbau nicht reißen |

Verschiedene Stile für verschiedene Fahrer

Wir wissen, dass Fahrer unterschiedliche BedürfnisseDeshalb machen wir drei Stile:

1. Standard-Hinterradabdeckung

- Passt wie das Originalteil

- Am besten für Straßenfahrer

- Einfach zu installieren

- $240 Startpreis

2. Breiter Hinterradkotflügel

- 30% mehr Abdeckung

- Am besten für regnerisches Wetter

- Schützt Ihre Kette und Schwinge

- Muss für Trackdays

3. Erweiterter Hinterradkotflügel

- 15cm längerer Schutz

- Am besten für Langstreckenfahrer

- Hält Taschen und Ausrüstung sauber

- Premium-Wahl für Touren

- Preisspanne $300-$350

Probleme mit anderen Kohlefasermarken

Andere Marken haben große Probleme:

- Lange Wartezeiten: Manche lassen dich warten 3-4 Wochen

- Schlechte Passform: Viele brauchen Bohren oder Schneiden passen

- Gefälschtes Carbon: Einige verwenden Vinyl in Carbonoptik über Fiberglas

- Hohe Preise: Viele laden $750 oder mehr

- Falsches Muster: Die meisten stimmen nicht überein Ducati OEM Karbonteile

Diese Probleme machen Ihre Fahrrad sieht schlecht aus Und Verschwenden Sie Ihr Geld.

Warum Kunden sich für unsere Kohlefaser entscheiden

Unsere Kunden lieben unsere Motorrad aus Kohlefaser Teile, weil:

- Versand innerhalb von 3 Tagen – nicht Wochen

- Passt perfekt – keine Änderungen erforderlich

- Sieht aus wie Fabrik – passt perfekt zu Ducati Carbon

- Kostengünstiger – sparen Sie Hunderte von Dollar

- Besser gemacht – echte Rennqualität

Echte Gewichtseinsparungen, die Sie spüren können

Schauen Sie, wie viel Gewicht, das Sie sparen:

| Teil | Lagergewicht | Unser Kohlenstoffgewicht | Gewichtsersparnis |

|---|

| Hinterradabdeckung | 450 g | 135 g | 315g (70%) leichter |

| Breiter Hugger | 550 g | 165 g | 385g (70%) leichter |

| Erweiterter Hugger | 600 g | 180 g | 420g (70%) leichter |

Dieses Gewicht liegt bei der Rückseite Ihres Fahrrads wo es ist am wichtigsten zur Handhabung!

Unsere Hinterradabdeckungen Installation in wenigen Minuten:

- Entfernen die serienmäßige Kunststoff-Radabdeckung (2 Schrauben)

- Position unser Carbonfaser-Radabdeckung

- Anziehen die gleichen 2 Schrauben

- Genießen Ihr neuer Look!

Kein Bohren. Kein Schneiden. Keine Probleme.

Funktioniert mit allen Ducati Panigale V4-Modellen

Unsere Hinterradabdeckungen passen all diese Fahrräder:

- Ducati Panigale V4 (2018-2024)

- Ducati Panigale V4S (2018-2024)

- Ducati Panigale V4R

- Ducati Panigale V4 Speciale

- Ducati Streetfighter V4

Sie arbeiten mit Serienauspuff Und Aftermarket-Systeme wie Akrapovic.

Spezieller UV-Schutz für lange Lebensdauer

Sonne kann Kohlefaser ruinierenUnsere spezielle Keramikbeschichtung:

- Blöcke 99% von UV-Strahlen

- Hält die mattes Finish sieht aus wie neu

- Verhindert Vergilbung

- Widersteht Kratzer

- Macht Reinigung einfach

Dies ist die gleiche Beschichtung Ducati verwendet für seine $4.000 Kohlefaserteile!

Was unsere Kunden sagen

„Ich habe das letztes Jahr auf meinem V4S installiert. Es sieht immer noch Brandneu nach 5.000 Meilen.“ – Mike S.

"Der Passform war perfektDie Installation hat 5 Minuten gedauert. Sieht aus wie ab Werk.“ – Tom R.

„Ich bin auf der Strecke gestürzt und alles ist kaputt gegangen, außer Carbon-Radkappe. Ich habe ein neues Fahrrad gekauft und die Radabdeckung daran angebracht!“ – Dave M.

Kohlefaser vs. Standardkunststoff – kein Wettbewerb

| Besonderheit | Kunststoff | Unsere Carbonfaser |

|---|

| Gewicht | Schwer (450 g) | Leicht (135 g) |

| Stärke | Bricht leicht | 5x stärker |

| Suchen | Einfacher schwarzer Kunststoff | Wunderschönes Carbongewebe |

| Schutz | Grunddeckung | Erweiterte Abdeckung |

| Lebensdauer | 2-3 Jahre | 10+ Jahre |

| Wert | Verliert an Wert | Wertsteigerung des Fahrrads |

Unsere kundenspezifische Carbonfaserherstellung

Als benutzerdefinierte Kohlefaser Hersteller, wir können auch herstellen:

- Sonderanfertigungen mit Ihrem Logo oder Ihren Farben

- Benutzerdefinierte Formen für spezielle Fahrräder

- Carbonfaser-Sets die perfekt zusammenpassen

- Ersatzteile die nirgendwo anders verkauft werden

Wir machen alles in unserer eigenen Fabrik. Keine Zwischenhändler. Keine Aufschläge.

Vervollständigen Sie Ihren Carbonfaser-Look

Unser Hinterradkotflügel ist nur der Anfang. Kombinieren Sie ihn mit unseren anderen Kohlefaser Teile:

- Vorderer Kotflügel

- Seitenwände

- Tankabdeckung

- Sitzbezug

- Kettenschutz

- Kettenradabdeckung

- Hitzeschilde

Alle mit dem gleiches perfektes mattes Finish übereinstimmen.

Besser als die großen Marken zum halben Preis

Sehen Sie, wie wir im Vergleich zu anderen Marken abschneiden:

| Marke | Gewichtsreduktion | Preis | Lieferzeit | Garantie |

|---|

| Unsere Carbonfaser | 70% | Preis auf Anfrage | 3 Tage | 2 Jahre |

| Vollsechs | 50% | $240-$750 | 5-10 Tage | 2 Jahre |

| Ilmberger | 70% | $270 | 3-4 Wochen | 1 Jahr |

| MotoComposites | Nicht angegeben | Nicht angegeben | Lagerartikel | 1 Jahr |

| Akoso | Nicht angegeben | $200-$400 | Nicht angegeben | Nicht angegeben |

OEM/ODM-Dienste für Geschäfte und Händler

Wir arbeiten auch mit:

- Motorradhändler

- Custom-Shops

- Rennteams

- Teilehändler

Wir können machen Ihre Markenteile mit:

- Ihr Logo

- Ihre Verpackung

- Ihre Design-Optimierungen

- Mengenpreise

Bestellen Sie noch heute Ihren Ducati Panigale V4S Carbonfaser-Hinterradkotflügel

Hör auf zu lassen Schlamm und Schmutz ruinieren Sie Ihre schöne Ducati. Hören Sie auf, mit schwere Kunststoffteile das sieht langweilig aus.

Holen Sie sich unsere V4S Carbonfaser-Hinterradkotflügel matt heute und genießen Sie:

- Schöne Carbonfaser-Optik

- 70% Gewichtsreduzierung

- Perfekte Werkspassform

- Schneller 3-Tage-Versand

- Einfache 5-Minuten-Installation

- 2 Jahre Garantie

Klicken Sie unten, um jetzt zu bestellen und Ihre Ducati noch heute umzugestalten!

BESTELLEN SIE JETZT IHREN HINTEREN KOHLEFASER-KOTFLÜGEL

FAQ – Antworten auf Ihre Fragen

F: Passt das auf meine Ducati Panigale V4S 2023? A: Ja! Es passt perfekt für alle Modelle von 2018 bis 2024.

F: Benötige ich für die Installation spezielle Werkzeuge? A: Nein, nur ein einfacher Inbusschlüssel, der mit Ihrem Fahrrad geliefert wurde.

F: Funktioniert es mit Akrapovic-Auspuffen? A: Ja, unser Radkappensatz funktioniert mit Original- und allen Aftermarket-Auspuffen.

F: Wie viel leichter ist es als das Original? A: Etwa 315 g leichter (Gewichtsreduzierung 70%).

F: Ist die matte Oberfläche die gleiche wie Ducati OEM Carbon? A: Ja, wir verwenden genau dieselbe Leinwandbindung mit 200 g/m² und Keramikbeschichtung.