So schneiden Sie Carbonfaserplatten: Die richtige Methode für optimale Ergebnisse

Das Problem: Das Schneiden von Kohlefaser ist schwierig

Versuchen Sie, Kohlefaserplatten zu schneiden, erzielen aber schlechte Ergebnisse? Viele Menschen haben dieses Problem. Kohlefaser ist sehr stabil, kann aber beim Schneiden brechen.

Schlechte Schnitte verschwenden Ihr Geld. Sie lassen Ihre Teile schlecht aussehen. Sie können Sie sogar durch winzige Staubpartikel verletzen, die in Ihre Lunge gelangen.

Warum ist es so schwer?

- Kohlefaser kann splittern

- Es entsteht gefährlicher Staub

- Normale Werkzeuge werden schnell stumpf

- Schlechte Schnitte ruinieren teure Materialien

Der Schmerz wird schlimmer

Wenn Sie die falschen Werkzeuge verwenden, wird es schnell schlimm:

- Wenn Sie nicht den richtigen Cutter verwenden, bekommt Ihr Projekt hässliche Kanten.

- Sie verschwenden Geld für Materialien

- Sie könnten gesundheitsschädlichen Staub einatmen

- Ihre Werkzeuge gehen kaputt

In unserer Fabrik sieht man das ständig. Man versucht, mit billigen Werkzeugen Geld zu sparen. Aber am Ende geben sie mehr aus, um Fehler zu beheben.

Die gute Nachricht: Wir wissen, wie wir das Problem beheben können

Mit Über 28 Jahre Erfahrung in der Herstellung von Kohlefaserteilen, wir kennen alle Tricks. Unsere benutzerdefinierte CNC-Kohlefaser Experten helfen Ihnen. Oder wir zeigen Ihnen, wie Sie es selbst richtig machen.

Lassen Sie uns Ihre Probleme beim Schneiden von Kohlefasern lösen!

Werkzeuge, die Sie für perfekte Schnitte benötigen

Wählen Sie das richtige Werkzeug für Ihre Arbeit:

| Werkzeugtyp | Gut für | Kosten | Fähigkeitsstufe |

|---|---|---|---|

| CNC-Maschine | Große Aufgaben, perfekte Schnitte | $$$$ | Pro |

| Diamant-Nasssäge | Mittlere Blätter | $$$ | Medium |

| Stichsäge mit Carbonblatt | DIY-Projekte | $$ | Einfach |

| Dremel-Werkzeug | Kleine, kurvige Schnitte | $ | Einfach |

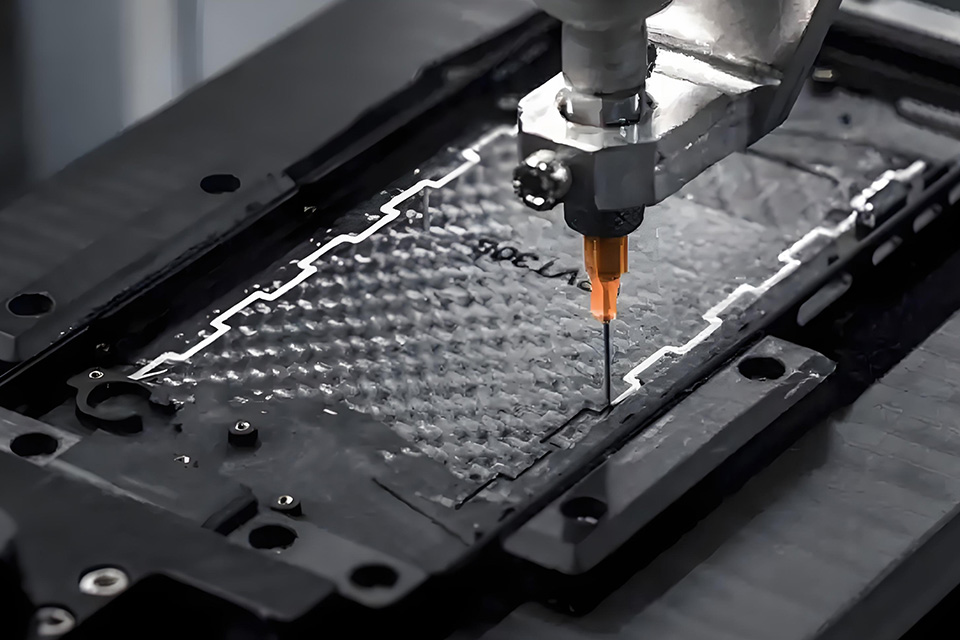

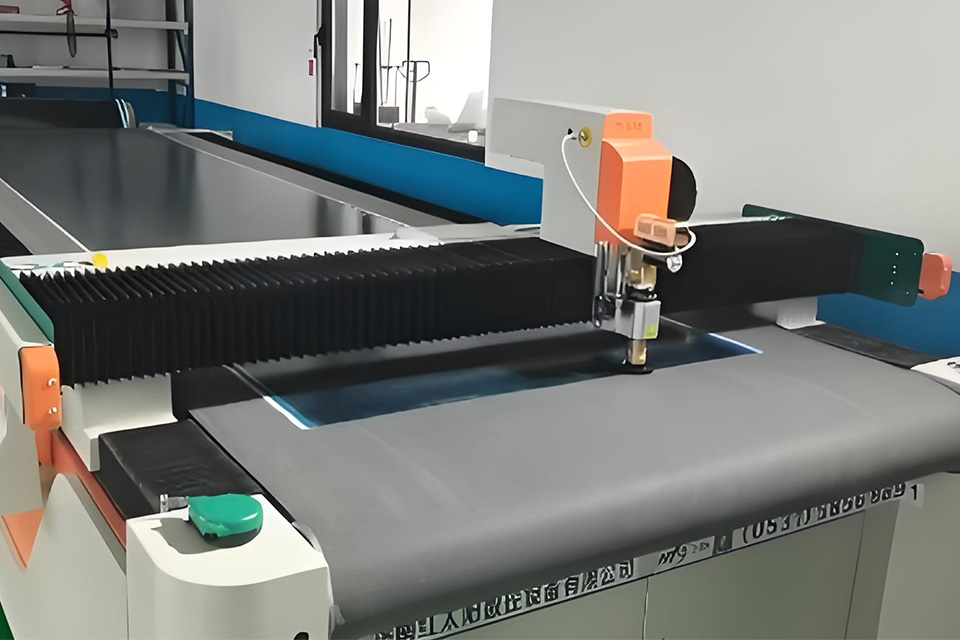

1. CNC für perfekte Schnitte

CNC-Schneiden eignet sich am besten für große Aufträge. Unsere Fabrik verwendet AMOR-CNC-Maschinen mit Hartmetallfräsern.

- Vibrationsschneidköpfe

- Staubkontrollsysteme

- Computerperfekte Schnitte

Profi-Tipp: CNC-Maschinen schneiden für beste Ergebnisse 1/16-Zoll-Blätter mit 10.000 U/min und 60 Zoll pro Minute.

2. Diamant-Nasssägen

Wasser hält Staub fern und ermöglicht saubere Schnitte im Laminat. Gut für:

- Blätter mittlerer Größe

- Gerade Linien

- Weniger Staubprobleme

3. Stichsägen aus Kohlefaser

Bosch stellt gute Kohlefaserblätter her, die:

- Hält 10-mal länger als herkömmliche Klingen

- Machen Sie sauberere Schnitte

- Kosten weniger als große Maschinen

4. Handwerkzeuge für kleine Arbeiten

Für kleine Arbeiten oder benutzerdefinierte Kohlefaser Teile:

- Rasierklingen (nur dünne Blätter)

- Dremel mit Metallschneidbits

- Feilen und Schleifpapier für Kanten

Schritt-für-Schritt-Anleitung für perfekte Schnitte

Schritt 1: Machen Sie sich bereit

Vor dem Schneiden:

- Sicherheitsausrüstung anlegen

- Staubmaske (N95 oder besser)

- Schutzbrille

- Handschuhe

- Markieren Sie Ihre Schnitte

- Verwenden Sie ein Lineal

- Markieren Sie mit einem Stift

- Zweimal messen!

- Staubkontrolle einrichten

- Arbeiten Sie draußen, wenn Sie können

- Verwenden Sie einen Staubsauger

- Bereich sauber halten

Schritt 2: Wählen Sie die Schnittmethode

Für Handwerkzeuge:

- Verwenden Sie eine Trägerplatte unter Ihrem Blatt

- Gehen Sie langsam und stetig vor

- Schneiden Sie, wenn möglich, in Faserrichtung

Für Elektrowerkzeuge:

- Stellen Sie die richtige Geschwindigkeit ein (siehe unsere Tabelle)

- Klemmen Sie Ihr Blatt fest

- Lassen Sie das Werkzeug die Arbeit machen – üben Sie keinen Druck aus

Schnittgeschwindigkeitstabelle

| Blechdicke | Werkzeuggeschwindigkeit | Vorschubgeschwindigkeit | Am besten für |

|---|---|---|---|

| 1/32″ (0,8 mm) | 10.000 U/min | 70 Zoll/min | Kleinteile |

| 1/16″ (1,6 mm) | 10.000 U/min | 60 Zoll/min | Die meisten Arbeitsplätze |

| 1/4″ (6,35 mm) | 8.000 U/min | 40 Zoll/min | Große Teile |

Schritt 3: Machen Sie Ihren Schnitt

Der richtige Weg:

- Schneiden Sie mit einer fließenden Bewegung

- Halten Sie den Druck gleichmäßig

- Folgen Sie Ihren Spuren

- Gehen Sie mit der Faserrichtung

Falsche Wege, die Probleme verursachen:

- Zu starkes Drücken

- Zu schnell fahren

- Verwendung stumpfer Werkzeuge

- Gegen den Strich schneiden

Schritt 4: Kanten fixieren

Nach dem Schneiden:

- Raue Kanten schleifen (120er-Körnung, dann 400er-Körnung)

- Staub mit Luft oder einer Bürste entfernen

- Schnittkanten bei Bedarf mit Harz versiegeln

Häufige Probleme und deren Behebung

Problem: Kanten brechen und splittern

Dies passiert mit 65% von DIY-Carbonfaserschnitten!

Beheben Sie das Problem:

- Verwenden Sie feinere Zahnklingen

- Langsamer schneiden

- Gehen Sie mit dem Faserkorn

- Trägermaterial verwenden

Problem: Zu viel Staub

Staub ist schlecht für Ihre Gesundheit und Ihren Arbeitsplatz.

Beheben Sie das Problem:

- Verwenden Sie wenn möglich Nassschnitt

- Tragen Sie eine gute Maske

- Verwenden Sie Vakuumsysteme

- Arbeiten Sie im Freien, um die Belastung durch Kohlefaserstaub zu minimieren.

Problem: Werkzeuge werden schnell stumpf

Kohlefaser belastet Werkzeuge sehr stark, insbesondere abrasive Werkzeuge.

Beheben Sie das Problem:

- Verwenden Sie diamantbeschichtete Werkzeuge

- Klingen häufiger austauschen

- Verwenden Sie Werkzeuge, die für Kohlefaser geeignet sind

- Überlassen Sie uns die harte Arbeit!

Warum unsere Fabrik helfen kann

Mit Über 28 Jahre Erfahrung Kohlefaser Teile, wir kennen jeden Trick.

Unsere Fabrik verfügt über:

- Industrielle CNC-Maschinen mit Hartmetallfräsern

- Erfahrene Techniker

- Staubkontrollsysteme

- Jedes Mal perfekter Schnitt

Wir fertigen Teile für:

- Auto aus Kohlefaser Teile

- Motorrad aus Kohlefaser Komponenten

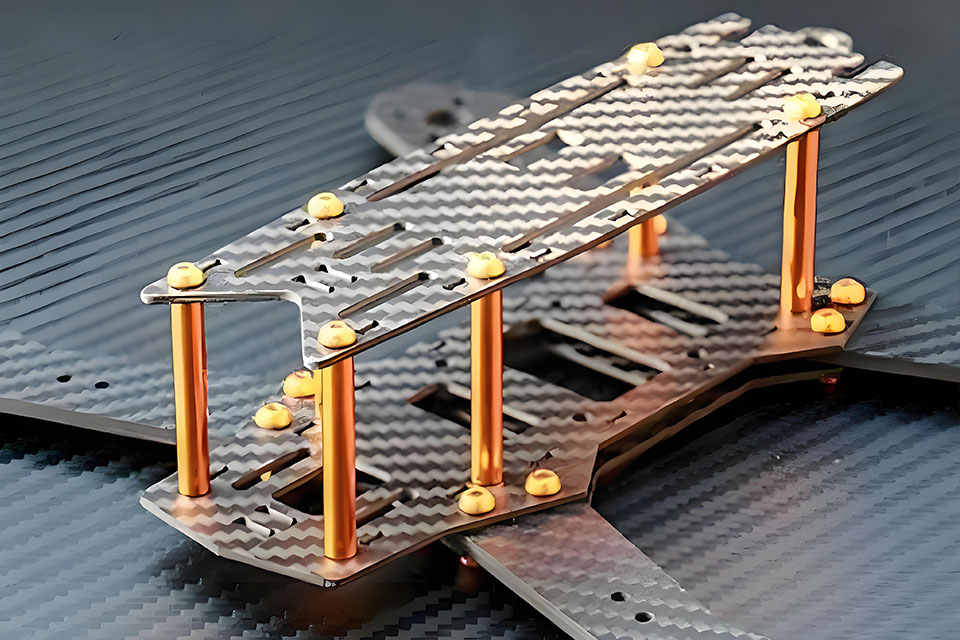

- Drohnenrahmen

- Kundenspezifische Projekte

Von uns verwendete Werkzeuge vs. DIY-Optionen

| Werkzeugtyp | Unsere Fabrik | DIY-Option | Ergebnisse |

|---|---|---|---|

| CNC-Fräser | $5.000+ Maschinen | – | Perfekte Schnitte |

| Diamantsägen | Industriequalität | $300-800 Heimmodelle | Gute Schnitte |

| Spezialklingen | Professional | $50-200 | Ok, Schnitte |

| Handwerkzeuge | Selten benötigt | $20-50 | Grundschnitte |

Warum sollten Sie uns Ihre Kohlefaser schneiden lassen?

Probleme beim Selberschneiden:

- Werkzeuge kosten viel

- Lernen braucht Zeit

- Fehler verschwenden Material

- Staub ist gesundheitsschädlich

Vorteile unseres Services:

- Auch bei der Arbeit mit Laminat gelingen jedes Mal perfekte Schnitte.

- Keine Werkzeugkosten für Sie

- Keine Gesundheitsrisiken

- Schnelle Bearbeitung

- 28+ Jahre Erfahrung

Unsere OEM/ODM-Services

Wir schneiden nicht nur Kohlefaser. Wir fertigen komplette Teile:

- Wir gestalten mit Ihnen

- Wir fertigen Prototypen

- Wir übernehmen die komplette Produktion

- Wir versenden weltweit

Unsere Stärken:

- 28+ Jahre Herstellung von Kohlefasern

- ISO-zertifizierte Fabrik

- Sonderanfertigungen willkommen

- Alles aus einer Hand

Echte Kundenprobleme, die wir gelöst haben

Fall 1: Rennteam-Teile

Problem: Das Team benötigte kundenspezifische Teile mit perfekten Schnitten

Was wir getan haben:

- CAD-Designs erstellt

- Mit CNC-Präzision schneiden

- Alle Kanten bearbeitet, um eine glatte Schnittlinie sicherzustellen.

- Gelieferte rennfertige Teile

Ergebnis: Das Auto war pro Runde 3,2 Sekunden schneller!

Fall 2: Probleme mit dem Drohnenhersteller

Problem: DIY-Schnitte waren ungleichmäßig und brachen

Was wir getan haben:

- Vorrichtungen für perfekte Schnitte

- Gebrauchte Diamantscheiben

- Alle Kanten versiegelt

Ergebnis: Drohnenrahmen hielten 5x länger!

Bereit für perfekte Carbonfaserteile?

Option 1: Wir machen es für Sie

Überlassen Sie alles unseren Experten. Erhalten Sie problemlos perfekte Teile.

Option 2: Wir schneiden, Sie beenden

Wir erledigen das Zuschneiden, Sie die Endmontage.

Option 3: Lernen Sie unsere Methoden kennen

Wir können unser über 28-jähriges Wissen weitergeben.

Werkzeuge, die Sie haben sollten

Wenn Sie Ihre Kohlefaser selbst schneiden möchten, besorgen Sie sich diese Werkzeuge:

Unverzichtbare Sicherheitsausrüstung:

- N95-Maske oder Atemschutzgerät

- Schutzbrille

- Handschuhe

Grundlegende Schneidwerkzeuge:

- Bosch Kohlefaser-Stichsägeblatt

- Dremel mit Metallschneidbits

- Feines Schleifpapier (120-400er Körnung)

Für bessere Ergebnisse:

- Diamant-Nasssäge

- Staubsammelsystem

- Spannsystem

Abschließende Gedanken

Das Schneiden von Kohlefaser kann schwierig sein. Mit den richtigen Werkzeugen und dem richtigen Know-how erzielen Sie jedoch gute Ergebnisse.

Oder machen Sie es sich einfach – lassen Sie unsere Fabrik mit 28+ Jahre Erfahrung tun Sie es für Sie! Wir schneiden Kohlefaser, den ganzen Tag, jeden Tag.

Kontaktieren Sie uns Jetzt für ein kostenloses Angebot für Ihren Bedarf beim Schneiden von Kohlefasern!