Sie wollen Ihren McLaren aufsehenerregend aussehen lassen? Unser Kohlefaserteile für die McLaren 570S, 570GT, Und 540C wird genau das tun! Diese Teile machen Ihr Sportwagen besser aussehen und auch schneller fahren. Hergestellt aus Trockenkohle das superstark und sehr leicht ist. Rennteams lieben unsere Teile. Autoteilehändler in großen Mengen kaufen können. Wir stellen sie in unserer eigenen Fabrik mit Spitzenmaschinen und intelligenten Mitarbeitern her.

Unser Kohlefaserteile passen genau wie die von McLaren aber weniger kosten. Sie sehen so gut aus, dass die Leute denken werden, dass sie mit Ihrem Auto geliefert wurden! Sie können ein Teil kaufen oder ein ganzes Set, damit Ihr Auto aussieht wie das schicke 600LT.

Warum bei uns kaufen?

- Direkt ab Werk – kein Zwischenhändler

- Perfekte Passform jedes Mal

- Schneller Versand an Rennteams und Geschäfte

- Großbestellungen Willkommen für Händler

- Kundenspezifische Teile können speziell für Sie angefertigt werden

Premium Dry Karosserie-Kit aus Kohlefaser für die Modelle McLaren 540C und 570S

Unser Carbonfaser-Bodykit ist für die McLaren 540C, 570S, Und 570GT Modelle von 2016-2020. Wir verwenden reale Trockenkohle - und nicht die billige, nassgelegte Variante. Dies bedeutet, dass Ihre Teile sein wird:

- 60% Feuerzeug als Originalteile

- 100% stärker als Fabrikteile

- UV-geschützt damit sie nicht gelb werden

Der Frontstoßstange aus Kohlefaser Und Seitenschweller in unserem Bausatz werden nach der gleichen Methode hergestellt, die für Rennsport Autos. Unsere Fabrik stellt Teile für echte Rennställe und jetzt können Sie diese Qualität auch für Ihr Straßenauto nutzen.

"Ich habe diese Carbonteile an meinem 570S angebracht und er sieht jetzt noch besser aus als der 600LT. Die Qualität ist genauso gut wie OEM, aber zum halben Preis." - Mark T., Besitzer eines Performance Shops

600LT Umbausatz - Rüsten Sie Ihren McLaren 540C oder 570S auf

Möchten Sie Ihre 570S oder 540C aussehen wie die heiße 600LT? Unser 600LT-Umbausatz hat alles, was Sie brauchen:

Der Kohlefaser-Seite Teile lassen Ihr Auto breiter und fieser aussehen. Die Heckmotor Gebiet erhält eine neue Motorhaubenabdeckung aus Kohlefaser die Ihren Motor zur Geltung bringt. Alle Teile verwenden die OEM Befestigungspunkte, damit sie genau wie die Werksteile passen.

Teile passen in die Tabelle:

| Teilename | McLaren 540C | McLaren 570S | McLaren 570GT | 600LT |

|---|

| Frontstoßstange | ✓ | ✓ | ✓ | – |

| Vorderlippe | ✓ | ✓ | ✓ | – |

| Seitenschweller | ✓ | ✓ | ✓ | – |

| Heckdiffusor | ✓ | ✓ | ✓ | – |

| Motorabdeckung | ✓ | ✓ | ✓ | – |

| Türschwellen | ✓ | ✓ | ✓ | ✓ |

Senna Style Kohlefaser-Haube und Aero-Teile

Willst du den wildesten Look? Unser Kohlefaser-Haube im Senna-Stil wird die Blicke auf sich ziehen! Wir machen auch Kohlefaser-Haube im P1-Stil Teile, die Ihr McLaren 570S oder 540C das Aussehen des Verdecks McLaren Autos.

Der Kohlefaser-Aero Teile, die wir herstellen:

- Luft besser schneiden

- Ihr Auto liegt besser auf der Straße

- Sieht super cool aus

- Damit Ihr Auto schneller fährt

Unser MSO-Diffusor aus Kohlefaser ist genau wie das echte Modell an die MSO Teil, kostet aber viel weniger. OEM-Ersatzspiegelkappen und andere Kleinteile können ebenfalls dazu beitragen, den vollen Carbon-Look zu erzielen.

Wie unsere Kohlefaserteile hergestellt werden

Wir verkaufen nicht nur Teile - wir stellen sie her! Unsere Fabrik macht Kohlefaserprodukte für:

- Rennteams

- Militärische Flugzeuge

- Raumfahrtunternehmen

- Besondere Fahrzeuge

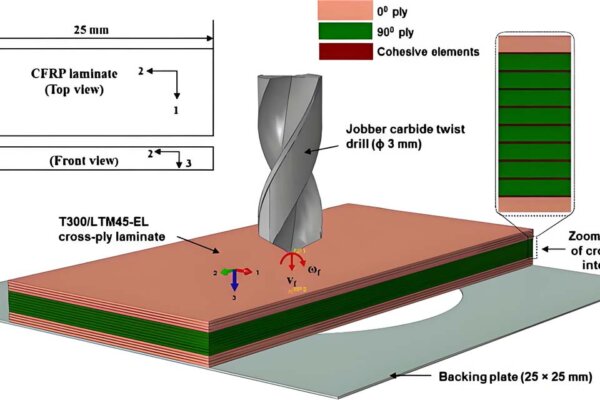

Wir verwenden vorimprägnierte Kohlefaser das in großen Öfen, den Autoklaven, gebacken wird. So entstehen die stärksten und leichtesten Teile, die Sie kaufen können. Nicht alle Kohlefaserteile werden auf die gleiche Weise hergestellt!

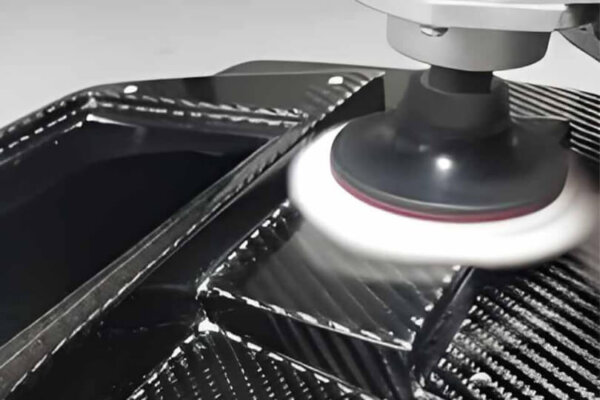

Unser Prozess:

- Perfekte Formen aus echten Autoteilen herstellen

- Kohlefaser von Hand verlegen - nicht mit der Maschine

- Backen bei hoher Hitze und hohem Druck

- Politur und Klarlack für Glanz

- Testanpassung an echten Fahrzeugen

- Supersicher verpackt für den Versand

Warum McLaren-Besitzer unsere Teile wählen

McLaren-Fans Und Leistungsstudios unsere Teile auswählen, weil:

- Geld sparen - 40-60% weniger als OEM

- Gleiche Qualität als Händlerteile

- Schneller Versand aus unserem großen Bestand

- Perfekte Passform jedes Mal

- Umfassende technische Hilfe wenn du es brauchst

570S-Besitzer sagen uns, dass sie es toll finden, dass unsere Teile genauso aussehen wie die Originalteile, aber so viel weniger kosten. Türschwelle aus Kohlefaser sind unsere meistverkauften Teile, weil sie einfach anzubringen sind und das Aussehen Ihres Fahrzeugs stark verändern.

"Ich habe Carbonteile von vielen Marken in die Autos meiner Kunden eingebaut. Dies sind die am besten passenden Aftermarket-Carbonteile, die ich je verwendet habe." - Tony R., Professionelle Änderungswerkstatt

Technische Daten unserer Carbonfaser

| Besonderheit | Unser Kohlenstoff | Fabrik-Kohlenstoff | Günstiger Kohlenstoff |

|---|

| Gewicht | Sehr leicht | Licht | Schwer |

| Stärke | Sehr hoch | Hoch | Medium |

| UV-Schutz | Ja | Ja | NEIN |

| Muster weben | 2×2 Köper | 2×2 Köper | Schmucklos |

| Klarlack | High-End | High-End | Basic |

| Fit | Perfekt | Perfekt | Kann Arbeit benötigen |

| Preis | $$ | $$$$ | $ |

So bestellen Sie Ihre McLaren Kohlefaserteile

Autoteilehändler Und Großhändler - wir bieten große Rabatte für Großbestellungen. Rennteams kann Eilbestellungen entgegennehmen, wenn Sie schnell Teile für den Renntag benötigen.

OEM und Erstausrüster - können wir kundenspezifische Carbonteile nach Ihren Vorgaben herstellen. Wir arbeiten jetzt mit vielen Autoherstellern zusammen, um ihre speziellen Teile herzustellen.

Leistungsstudios - werden Sie Händler und erhalten Sie unseren Katalog mit allen unseren Kohlefaserteile für McLaren und andere Marken.

Zum Bestellen:

- Wählen Sie die gewünschten Teile aus

- Teilen Sie uns Ihr Automodell und Baujahr mit

- Versandgeschwindigkeit wählen

- Zahlung per Überweisung oder Kreditkarte

- Schnelles Auffinden von Informationen

- Viel Spaß mit Ihrem neuen Carbon-Look!

Wir liefern an Rennstrecken, Geschäfte und Händler in der ganzen Welt. Unsere Boxen sind dafür gemacht, Ihre Kohlefaserteile sicher, egal wie weit sie gehen.

Warten Sie nicht, bis Ihr McLaren fantastisch aussieht! Der beste McLaren Sportwagen ist eins mit unserem Kohlefaserteile darauf!

ZUSAMMENFASSUNG: Verwandeln Sie Ihr McLaren 570S oder 540C mit unseren erstklassigen trockenen Kohlefaserteilen! Unsere Komponenten in Rennqualität bieten eine perfekte OEM-Passform mit 60%-Gewichtseinsparungen, erhöhter Festigkeit und aufsehenerregendem Stil zur Hälfte des Händlerpreises. Erhältlich für einzelne Upgrade oder komplette 600LT Umwandlung.