What is T700 Carbon Fiber? Properties, Uses, and Comparisons

Einführung

T700 Kohlefaser is a high-performance material made by Toray Industries. It’s stronger than steel but weighs much less. Engineers use it to build airplanes, race cars, and sports equipment. When you need something both light and tough, T700 delivers.

This material changed how we build things. From Boeing 787 Dreamliner wings to BMW i3 passenger cells, T700 makes vehicles lighter and stronger. Let’s explore what makes this carbon fiber so special.

What Makes T700 Carbon Fiber Special?

The Science Behind the Strength

Kohlefaserverbundwerkstoffe are made from thin strands of carbon atoms. These strands are woven together like fabric. Think of it like rope—one thread breaks easily, but many threads twisted together become incredibly strong.

Torayca T700S stands out because of how it’s manufactured. The process heats special materials to extreme temperatures. This creates long chains of carbon atoms lined up perfectly. The result? A material that’s five times stronger than steel at just one-quarter the weight.

Technical Properties That Matter

Here’s what makes T700 work so well:

| Eigentum | T700 Value | What It Means |

|---|---|---|

| Zugfestigkeit | 4,900 MPa | How much pulling force it can handle before breaking |

| Modulus of Elasticity | 230 GPa | How stiff it is—resists bending |

| Dichte | 1.8 g/cm³ | Lighter than aluminum (2.7 g/cm³) |

| Thermal Conductivity | Niedrig | Doesn’t transfer heat quickly |

| Electrical Conductivity | Non-conductive | Won’t carry electricity |

Der Zugfestigkeit number is huge. Steel typically breaks at around 400-500 MPa. T700 handles nearly ten times more stress.

Young’s modulus measures stiffness. At 230 GPa, T700 doesn’t flex much under pressure. That’s why aerospace carbon fiber engineers love it for aircraft wings that must stay rigid during flight.

Weight Savings That Change Everything

Carbon fiber weight advantages transform entire industries. A Carbonfaser-Fahrrad frame weighs 40% less than aluminum. That means faster rides with less effort.

In cars, weight reduction improves everything. The BMW i-Series uses T700 in its passenger cell. This saves 250 kg compared to steel construction. Lighter cars accelerate faster, stop quicker, and use less fuel or battery power.

How T700 Compares to Other Carbon Fibers

T700 vs T300: The Popular Choice

T300 carbon fiber costs less but offers lower performance. Here’s the breakdown:

| Besonderheit | T300 | T700 |

|---|---|---|

| Zugfestigkeit | 3,530 MPa | 4,900 MPa |

| Cost per kg | $20 | $30-$50 |

| Am besten für | Consumer products | High-performance applications |

| Common Uses | Sporting goods, basic drones | Aerospace, luxury vehicles |

T300 works fine for fishing rods or entry-level bike frames. But when you need maximum strength—like in a Formel 1 chassis—T700 becomes essential.

T700 vs T800: When to Go Premium

T800 Kohlefaser sits at the top of the performance ladder:

- Zugfestigkeit: 5,490 MPa (12% stronger than T700)

- Kosten: $80/kg (nearly double T700’s price)

- Anwendungen: Military aircraft, SpaceX rockets, high-end race cars

Is T800 worth the extra cost? Sometimes. NASA uses it for spacecraft where every gram matters. But for most applications, T700 offers the best balance of strength and cost.

T700 vs T1000: The Ultra-Premium Option

T1000 carbon fiber represents cutting-edge technology. Lockheed Martin uses it in stealth aircraft. However, it costs so much that only defense and space programs can afford it.

For commercial projects, T700 makes more sense. It delivers 80% of T1000’s performance at 30% of the cost.

Real-World Applications

Aerospace: Flying Higher and Lighter

Aerospace carbon fiber revolutionized aviation. The Boeing 787 uses T700 in wing components. This reduces aircraft weight by thousands of pounds.

Lighter planes burn less fuel. Airbus reports that carbon fiber composites improve fuel efficiency by 20%. Over a plane’s lifetime, that saves millions of dollars and reduces carbon emissions.

Drohnen rely heavily on T700. DJI builds professional drone frames from this material. A lighter drone flies longer and carries better cameras. Military drones from Northrop Grumman use T700 for extended missions.

Automotive: Speed and Efficiency

Carbon fiber in automotive engineering has grown dramatically. Here’s where you’ll find T700:

Luxury Supercars

- Lamborghini uses T700 for body panels

- Ferrari builds entire chassis from carbon fiber composites

- McLaren Automobilbau combines T700 with aluminum for hybrid structures

- Pagani handcrafts carbon fiber interiors and exteriors

Elektrofahrzeuge Der Tesla Model S Plaid uses carbon fiber in its battery housing. BMW i3 proves that carbon fiber cars can be mass-produced affordably.

Weight reduction is critical for EVs. Batteries are heavy. Using T700 for the body structure offsets battery weight and extends driving range.

High-Performance Components

- Kohlenstoff-Revolution makes the world’s first one-piece carbon fiber wheels

- Carbon fiber in motorsports includes suspension parts and drive shafts

- Racing helmets use T700 for maximum protection at minimum weight

If you’re interested in learning more about Autos aus Kohlefaser, expert manufacturers can help you understand the possibilities.

Sports Equipment: Breaking Records

Carbon fiber in bicycles changed competitive cycling. Specialized, Trek, Und Pinarello all use T700 in high-end frames. Professional riders win races because their bikes weigh less and transfer power more efficiently.

Tennisschläger made from T700 let players swing faster. The carbon fiber stiffness transfers more energy to the ball.

Golfschläger with T700 shafts hit farther. The material’s low weight allows faster club head speeds without losing control.

Angelruten benefit from T700’s flexibility and strength. You can feel a fish bite better, and the rod won’t break when landing big catches.

Industrial and Defense Applications

Carbon fiber in wind turbines makes blades longer and more efficient. Vestas Und Siemens build turbine blades up to 80 meters long. Only carbon fiber composites can span that distance without breaking.

Military drones Und UAVs need T700 for stealth missions. The material doesn’t reflect radar signals like metal does.

Ballistic armor Und bulletproof vests use carbon fiber composites for lightweight protection. Soldiers can move faster while staying safe.

Carbon fiber in prosthetics helps amputees walk and run naturally. Carbonfaser-Fußeinlagen provide the perfect combination of flexibility and support. Learn more about Carbonfaser-Fußeinlagen for medical applications.

Herstellungsprozess

How T700 Gets Made

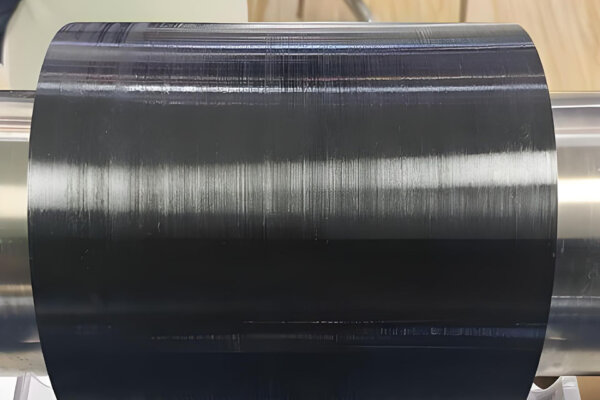

Carbon fiber manufacturing starts with a material called polyacrylonitrile (PAN). Here’s the process:

- Spinning: PAN gets stretched into thin fibers

- Stabilisierung: Fibers are heated to 200-300°C in oxygen

- Verkohlung: Temperature rises to 1,000-2,000°C without oxygen

- Oberflächenbehandlung: Chemical coating improves bonding with resins

- Größen: Protective coating prevents damage during handling

Toray Industries perfected this process. Their quality control ensures every batch meets strict standards.

Creating Finished Parts

Carbon fiber prepreg is partially cured material ready for molding. Manufacturers lay up sheets of prepreg in molds, then cure them in an autoclave (a high-pressure oven).

Carbon fiber 3D printing is emerging as a new technique. However, it can’t yet match the strength of traditional layup methods.

Working with a professional Hersteller von Kohlefaserverbundwerkstoffen ensures your parts meet specifications.

Advantages of T700 Carbon Fiber

The Good Stuff

Verhältnis Stärke/Gewicht: This is T700’s superpower. You get steel’s strength at aluminum’s weight. Actually, even better than that comparison.

Korrosionsbeständigkeit: Unlike steel, carbon fiber doesn’t rust. Boats made with T700 last decades without corrosion problems. Carbon fiber in marine applications has transformed yacht design.

Ermüdungswiderstand: Metal parts break after repeated stress cycles. T700 lasts ten times longer under the same conditions. NASA Materials Study confirmed this advantage.

Thermische Stabilität: T700 handles high temperatures without weakening. Jet engines, race car brakes, and industrial equipment benefit from this property.

Design Flexibility: Carbon fiber weave types can be oriented in different directions. Engineers control where the strength goes by changing fiber direction.

Vibration Damping: T700 absorbs vibrations better than metal. That’s why high-end speakers and musical instruments use it.

Real Performance Numbers

According to CompositesWorld Market Report, T700 delivers:

- 5x stärker than steel by weight

- 10x longer fatigue life als Aluminium

- 40% Gewichtsreduzierung compared to aluminum structures

- 20% fuel efficiency improvement in aircraft

Disadvantages and Limitations

The Not-So-Good Stuff

Kosten: At $30-50 per kilogram, T700 costs more than most metals. High-volume production helps reduce prices, but it’ll never be as cheap as steel.

Difficult Repairs: When metal dents, you hammer it out. Carbon fiber cracks can’t be easily fixed. Damaged parts often need complete replacement.

Carbonfaser-Recycling: This is a big problem. Traditional recycling doesn’t work. Pyrolysis (heating without oxygen) can recover fibers, but it’s energy-intensive and expensive. The Journal of Cleaner Production (2021) notes this environmental challenge.

Manufacturing Complexity: Making carbon fiber parts requires expensive equipment and skilled workers. You can’t just stamp out parts like with sheet metal.

Brittleness: While incredibly strong, carbon fiber can fail suddenly. Metal bends before breaking, giving warning. Carbon fiber just snaps.

Electrical Conductivity: For some applications, being non-conductive is a problem. Electronics mounting sometimes needs metal fasteners.

Safety Considerations

Carbon fiber failure modes differ from metal. Parts don’t show fatigue damage until they break. This requires different inspection methods.

In crashes, carbon fiber splinters into sharp fragments. Race car designers must contain these with protective layers.

Cost Analysis

What You’ll Pay

| Application | T700 Cost Impact | Alternative Cost |

|---|---|---|

| Bicycle frame | $800-$3,000 | Aluminum: $200-$800 |

| Car body panel | $500-$2,000 per part | Steel: $50-$200 |

| Drone frame | $100-$500 | Plastic: $20-$100 |

| Aircraft component | $10,000+ | Aluminum: $2,000-$5,000 |

The price looks high initially. However, lifecycle costs tell a different story.

Long-Term Value

Carbon fiber durability means parts last longer. A carbon fiber bike frame might cost three times more than aluminum but last twice as long and perform better throughout its life.

In aerospace, fuel savings quickly offset higher material costs. Boeing Composites Report (2015) showed the 787’s carbon fiber structure pays for itself in fuel savings within a few years.

Choosing the Right Carbon Fiber Grade

When T700 Makes Sense

Use T700 when you need:

- High strength with low weight

- Long-term durability

- Korrosionsbeständigkeit

- Good fatigue resistance

- Professional-grade performance

When to Choose Alternatives

Pick T300 if:

- Budget is tight

- Moderate performance is acceptable

- Consumer-level products

Choose T800 or higher if:

- Absolute maximum strength required

- Aerospace or military applications

- Cost is secondary to performance

Consider fiberglass or Kevlar when:

- Impact resistance matters more than weight

- Much lower costs needed

- Electrical insulation is critical

Working with Carbon Fiber Professionals

Finding the Right Partner

Kundenspezifische Kohlefaser projects need experienced manufacturers. Look for companies with:

- Aerospace certifications (FAA, ASTM D3039 compliance)

- Design engineering support

- Multiple manufacturing methods (layup, filament winding, compression molding)

- Quality testing equipment

A qualified Auftragswerk für Verbundwerkstoffe can guide material selection and optimize designs.

Design Considerations

Carbon fiber behaves differently than metal. Professional engineers understand:

- Fiber orientation für maximale Stärke

- Layup schedules that balance weight and performance

- Joint design that won’t create weak points

- Testing protocols that verify strength

Future Developments

What’s Coming Next

Carbon fiber in sustainable manufacturing is improving. Researchers are developing bio-based precursors to replace petroleum-derived PAN. This would reduce environmental impact.

Carbon fiber in graphene composites shows promise. Adding graphene could increase strength by another 50% without adding weight.

Carbon fiber in nanotechnology applications are emerging. Ultra-thin carbon fiber materials might revolutionize electronics and medical devices.

Automated manufacturing will reduce costs. AI-driven manufacturing systems can lay up parts faster and more consistently than human workers.

Market Growth

Carbon fiber in green energy is expanding rapidly. Wind turbines, electric vehicles, and hydrogen storage all need lighter materials. Market analysts predict 15% annual growth through 2030.

Carbon fiber in EV lightweighting will become standard. As batteries improve and costs fall, more manufacturers will adopt carbon fiber body structures.

Häufig gestellte Fragen

Is T700 carbon fiber stronger than steel?

Yes. T700 is five times stronger than steel when you compare weight. A steel beam and a T700 beam of equal strength show dramatic differences—the carbon fiber weighs 75% less.

Why is T700 used in drones?

Carbon fiber in drones offers the perfect combination. Drones need to be light to fly longer. But they also must be strong enough to handle crashes and carry equipment. T700 delivers both.

Can you repair T700 carbon fiber?

Sort of. Minor surface damage can be patched. But structural damage usually requires part replacement. Unlike metal, carbon fiber can’t be welded or easily reformed.

How long does T700 last?

With proper care, T700 lasts decades. Carbon fiber durability exceeds metal in most environments. No rust or corrosion means longer life in harsh conditions.

What’s the difference between T700 and AS4 carbon fiber?

AS4 Carbon Fiber (hergestellt von Hexcel) offers similar performance to T700. Both have tensile strengths around 4,900 MPa. The choice often depends on supplier relationships and regional availability.

Is T700 safe for medical use?

Yes. Carbon fiber in medical devices includes prosthetic limbs, orthopedic braces, and surgical instruments. The material is biocompatible and doesn’t cause allergic reactions.

Why does T700 cost so much?

Carbon fiber cost reflects complex manufacturing. The precursor materials are expensive. The process requires high temperatures, special equipment, and quality control. As production scales up, prices gradually decrease.

Can T700 handle extreme temperatures?

T700 maintains strength up to 300-400°C. Beyond that, the resin matrix (not the fiber itself) starts breaking down. For extreme heat applications, special high-temperature resins are used.

Abschluss

T700 Kohlefaser represents a sweet spot in advanced materials. It’s strong enough for demanding applications but costs less than premium grades like T800 or T1000.

Aus aerospace engineering Zu sporting goods, T700 makes products lighter, stronger, and more efficient. The Boeing 787 flies farther. The BMW i3 drives longer on a charge. Professional cyclists win races.

Yes, T700 costs more than traditional materials. But when performance matters—when weight savings translate to speed, efficiency, or capability—this carbon fiber delivers value.

The future looks bright for T700. As manufacturing improves and costs fall, more industries will adopt this remarkable material. Next-gen materials will build on T700’s foundation, but this workhorse grade will remain essential for decades.

Whether you’re building aircraft, designing benutzerdefinierte Kohlefaser parts, or just curious about advanced materials, understanding T700 helps you make better decisions.

Strong. Light. Durable. That’s T700 carbon fiber in three words.

About the Author

This article was written by engineers and sales specialists from Chinacarbonfibers, a manufacturer specializing in custom carbon fiber components for automotive, aerospace, and industrial applications, with over 20 years of experience working with Toray T700, T300, and T800 materials.