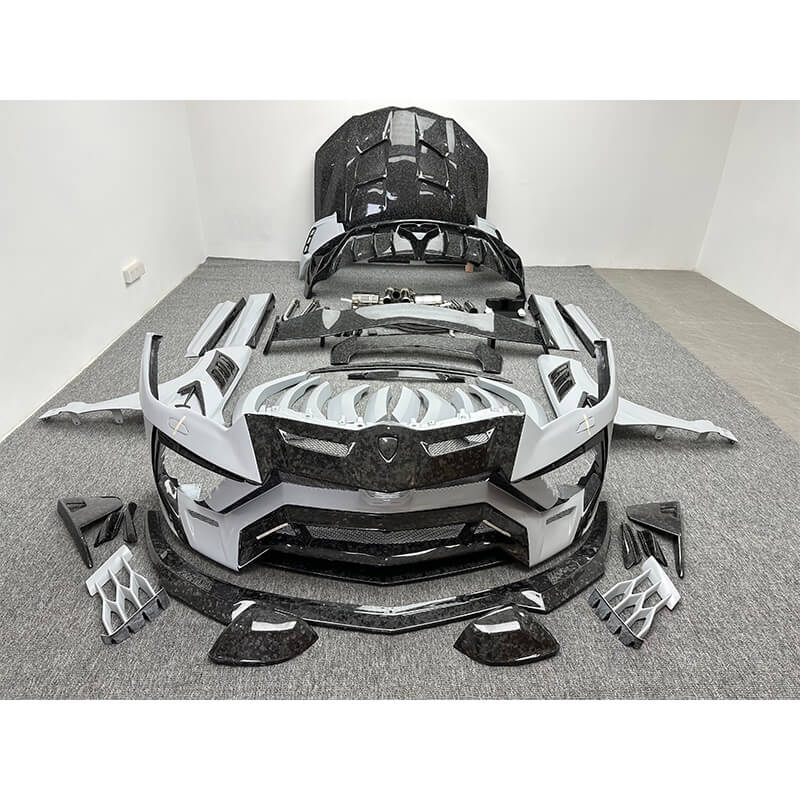

Kit básico de fibra de carbono forjada de alta calidad para piezas personalizadas de gama alta

Bienvenido al mundo de fibra de carbono forjada¡! Nuestro kit de inicio le ayuda a hacer partes asombrosas para coches, aviones, equipos deportivos y mucho más. Somos una fibra de carbono personalizada planta de fabricación de productos con años fabricando las mejores piezas de carbono.

¿Por qué elegir nuestro kit?

- Fácil de usar - incluso si eres nuevo en fibra de carbono

- Materiales de primera calidad - igual que en los coches de lujo

- Soporte completo - nuestro equipo le ayuda en cada paso

- Opciones personalizadas - fabricar piezas que se ajusten exactamente a sus necesidades

- Envío rápido - empiece ahora mismo

Qué es la fibra de carbono forjada y por qué es increíble

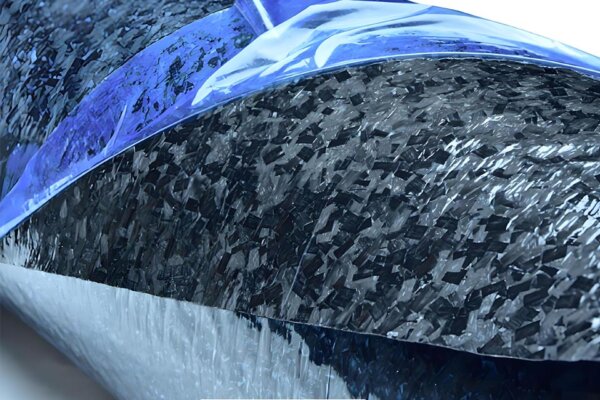

La fibra de carbono forjada es un nuevo camino para fabricar piezas de carbono. Utiliza carbón troceado mezclado con resina para fabricar piezas resistentes y de buen aspecto. A diferencia de fibra de carbono tejidaEl carbono forjado tiene un aspecto de mármol que a mucha gente le encanta.

El forjado carbón fibra El proceso comienza con fibras de carbono cortadas que se mezclan con resina epoxídica. Entonces utilizamos calor y presión para fabricar la pieza final. De este modo se consiguen piezas muy resistentes pero también de gran aspecto. Nuestros clientes en aeroespacial, automoción, y equipo deportivo Me encanta que las piezas de carbono forjado sean tan ligeras como resistentes. El patrón aleatorio de fibras picadas juntas da a cada pieza un aspecto único que destaca.

Contenido del kit completo de desarrollo de fibra de carbono forjada

Nuestro kit de inicio tiene todo lo que necesita para empezar a hacer componentes forjados de fibra de carbono. Cada el kit incluye:

| Artículo | Cantidad | Objetivo |

|---|

| Remolque de carbono picado | 500g | Material de la fibra principal |

| Resina epoxi de alta calidad | 1L | Agente aglutinante |

| Endurecedor | 500 ml | Activa la resina |

| Cera de liberación | 100g | Para facilitar la extracción de piezas |

| Molde de compresión (muestra) | 1 | Para dar forma a las piezas |

| Manual de instrucciones | 1 | Guía paso a paso |

| Guantes de seguridad | 2 pares | Protección |

| Recipientes de mezcla | 5 | Para la preparación de la resina |

El kit de desarrollo de fibra de carbono forjada está pensado tanto para nuevos usuarios como para profesionales. Nuestro sistema de resina epoxi es el mismo que utilizamos en nuestra fábrica para alto rendimiento regiones.

"Este kit ha cambiado nuestra forma de fabricar prototipos. La calidad es increíble y el equipo de soporte nos ayudó en cada paso." - John M., Ingeniero de diseño de automoción

Cómo fabricar increíbles productos de fibra de carbono

Haciendo piezas forjadas de fibra de carbono es fácil con nuestro kit. He aquí cómo:

- Mezclar la resina - Combinar el resina epoxídica y endurecedor a la derecha proporción de resina

- Preparar el carbono - Consigue tu carbón troceado listo

- Combinar materiales - Mezclar el fibra y resina bien juntos

- Llenar el molde - Ponga la mezcla en su moldes de compresión

- Aplica presión – Comprimir el material para eliminar el aire

- Curar - Deja que se endurezca según nuestra guía

- Finalizar - Retire y pula su carbono forjado acabado parte Puede utilizar nuestro kit con un Molde impreso en 3D o nuestro molde de compresión de dos partes fabricado de metal. Ambos funcionan muy bien para hacer carbono sólido regiones. Consejos para obtener mejores resultados:

- Utilice siempre cera desmoldeante en spray en sus moldes

- Siga exactamente sistema de resina instrucciones de mezclado

- Aplique una presión uniforme cuando utilizando una compresión técnica

- Lijar y pulir para forjado brillante finalizar

Especificaciones técnicas de nuestros materiales de carbono forjado

Nuestro fibra de carbono real materiales ofrecen un excelente rendimiento mecánico para todo tipo de proyectos:

- Resistencia a la tracción: 3500 MPa

- Densidad: 1,6 g/cm³

- Resistencia al calor: Hasta 180°C

- Contenido de resina: 40% en peso

- Longitud de la fibra: 25 mm estopa picada

- Tiempo de curación: 24 horas a temperatura ambiente o 4 horas a 80°C El piezas de fibra de carbono de nuestro kit se cortan a la medida perfecta para layup y la mejor fuerza. Nuestro molde de resina funciona tanto con moldeado por compresión sólido técnicas y resina impresa regiones.

Industrias que adoran nuestra fibra de carbono forjada

Nuestro productos de fibra de carbono se utilizan en muchas industrias punteras:

- Automóvil y motocicleta

- Piezas del tablero

- Paneles de carrocería

- Acabado interior

- Aeroespacial

- Componentes de cabina

- Piezas no estructurales

- Accesorios a medida

- Equipo deportivo

- Cabezas de palos de golf

- Componentes de bicicleta

- Piezas de raquetas de tenis

- Equipos médicos

- Carcasas de equipos de imagen

- Componentes protésicos

- Ayudas a la movilidad ligeras

- Electrónica de consumo

- Fundas para teléfonos

- Fundas para portátiles

- Carcasas de altavoces

El proceso de moldeo que utilizamos hace que las piezas tengan un aspecto estupendo y funcionen bien. Cuando hebras de carbono se presionan con la derecha cantidad de resinafabrican piezas mejores que las normales laminado de carbono.

Por qué elegir nuestra fibra de carbono forjada en lugar de los métodos tradicionales

| Característica | Carbono forjado | Tejido tradicional | Unidireccional |

|---|

| Mirar | Patrón de mármol | Tejido regular | Líneas rectas |

| Fortaleza | Muy alto | Alto | Mayor en una dirección |

| Facilidad de uso | Más fácil | Medio | Más difícil |

| Residuos | Muy bajo | Medio | Alto |

| Curvas | Excelente | Limitado | Limitado |

| Costo | Medio | Alto | Más alto |

Cuando tu comprar fibra de carbono forjada con nosotros, obtendrá materiales fáciles de trabajar. A diferencia de carbono unidireccional o preimpregnado materiales, nuestro carbono forjado es más tolerante con las formas complejas.

Nuestro CT12 picado sistema de fibra de carbono puede colocado en un molde de casi cualquier forma. Esto la hace perfecta para fabricar piezas complejas que serían difíciles de fabricar con una máquina normal. fibra de carbono tejida.

Ventajas de nuestro proceso de carbono forjado:

- Menos residuos que los métodos tradicionales

- Mayor rapidez de producción

- Mejor para formas complejas

- Cada pieza tiene un aspecto único

- Más fuerte en múltiples direcciones

Usamos lo mismo forja técnicas como los fabricantes de coches de lujo, pero póngalas al servicio de sus proyectos. Nuestro materiales compuestos se someten a las pruebas más exigentes.

Historias de éxito de clientes

Nuestro piezas de fibra de carbono han ayudado a muchas empresas:

"Cambiamos al carbono forjado para nuestras piezas de moto y las ventas subieron 30%. A los clientes les encanta el aspecto único". - Mike T., tienda de motocicletas Custom

"Las piezas aeroespaciales que fabricamos con este sistema superaron todas nuestras pruebas. El ahorro de peso es asombroso". - Sarah L., Proveedor aeroespacial

Nuestra línea de equipamiento deportivo recibió un gran impulso cuando añadimos fibra de carbono forjada opciones". - David K., Fabricante de equipamiento deportivo

Cuando trabaje con nuestro componentes forjados de fibra de carbonoSi es usted un empresario, se unirá a empresas que valoran la calidad y la innovación. Nuestra Resina de revestimiento XCR proporciona a las piezas un acabado que dura años.

Cómo pedir sus soluciones personalizadas de fibra de carbono

Listo para empezar a hacer piezas forjadas de fibra de carbono? He aquí cómo hacer el pedido:

- Contacte con nuestro equipo - Háblenos de su proyecto

- Obtener un presupuesto personalizado - Crearemos un paquete que se adapte a sus necesidades

- Reciba su kit – Envío rápido a todo el mundo

- Empezar a crear - Con todo nuestro apoyo

Para proyectos de mayor envergadura, ofrecemos fibra de carbono personalizada producto fabricación. Nuestra fábrica puede fabricar piezas desde pequeñas a muy grandes utilizando nuestros avanzados moldes de compresión y un equipo de expertos.

Opciones de pedido:

- Kits de iniciación para probar y aprender

- Creación de moldes personalizados

- Producciones completas

- Envases de sólo material

- Formación y apoyo

No espere a hacer carbono piezas que sorprenderán a sus clientes. Nuestro kit de desarrollo de fibra de carbono forjada es el primer paso para crear piezas que destaquen. Póngase en contacto con nosotros hoy mismo para unirse a la revolución de la fibra de carbono.

Resumen: Nuestro carbono forjado premium Kit básico de fibra le ofrece todo lo necesario para crear impresionantes piezas de carbono de calidad profesional. Gracias a su aspecto marmóreo, su resistencia superior y nuestra asistencia experta, en muy poco tiempo estará creando increíbles componentes personalizados para automoción, aeroespacial y mucho más.