Stand next to a Lamborghini Urus and you can feel it before you hear it — that quiet pulse of potential energy waiting beneath the sculpted body. Now imagine that same form draped entirely in koolstofvezel, its woven texture shimmering under the light like a living surface. The weight drops, the aerodynamics sharpen, and something intangible happens: presence turns into performance.

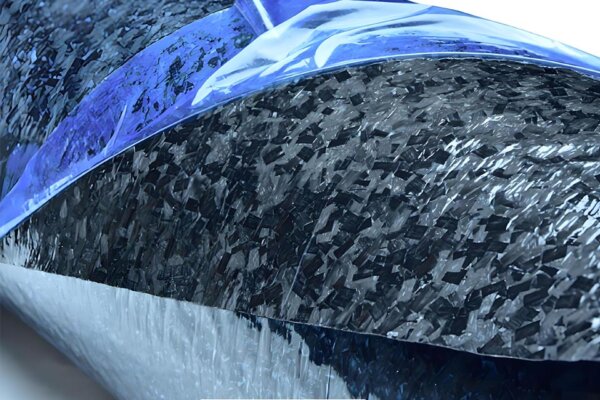

Bij Chinakoolstofvezels, this transformation is more than visual. It’s born from nearly three decades of work with CFRP (Carbon Fiber Reinforced Polymer) — the same aerospace-grade material trusted by Automobili Lamborghini S.p.A., Novitec, Herenhuis, En 1016 Industrieën. Elk Lamborghini Urus carbon fiber body kit is hand-laid from Toray T700 prepreg, autoclave-cured, and finished by artisans who still check every weave alignment by sight and touch.

This is not a cosmetic add-on. This is engineering made visible.

The Philosophy Behind Carbon

Carbon fiber isn’t simply “lightweight.” It’s a dialogue between science and emotion — between pressure, heat, and intention.

De Urus, with its 4.0-liter twin-turbo V8, already defines the concept of a Super SUV. But when you replace its metal panels with autoclave-cured prepreg carbon, every acceleration feels more urgent, every corner more exact.

The numbers tell one story:

- Tot 45% weight reduction compared with OEM plastic.

- Drag reduced by 6%, downforce increased by 18% at 250 km/h.

- Thermal stability beyond 150 °C under hood.

But the feeling tells another: a sense of mechanical purity — less noise, more connection. That’s what true carbon craftsmanship delivers. For a broader context on how carbon reshapes performance across platforms, explore our notes on koolstofvezel auto's.

Prepreg vs. Wet Carbon — What’s Beneath the Gloss

Anyone can copy the look of carbon fiber; few understand its anatomy.

Wet-layup carbon is popular because it’s inexpensive, but it’s inconsistent — heavy resin, air bubbles, distortion under UV. It’s the difference between imitation and integrity.

Prepreg (Dry Carbon), used by Lamborghini’s race programs and our own production line, is pre-impregnated with resin and baked in a pressurized autoclave. The result is a flawless, pinhole-free surface, crystal-clear resin, and structural density that no hand-lay method can reach.

| Aspect | Prepreg Carbon (Dry) | Natte koolstof |

|---|

| Proces | Autoclaaf uitharding | Manual Wet Layup |

| Sterkte-gewichtsverhouding | 7× Steel | 3× Steel |

| Resin Ratio | Controlled (38%) | Uncontrolled (50 %+) |

| Finish | Optical-grade UV clear coat | Kan na verloop van tijd geel worden |

You don’t just see the difference — you feel it when the panel vibrates less, fits tighter, and shines deeper after years of exposure.

Exterior — A Sculpture in Motion

When light glides over carbon fiber panels, it reveals something steel never could: motion even in stillness.

Ons Lamborghini Urus forged carbon and twill kits are designed not only to look precise but to reshape airflow.

Front Presence

- Urus Carbon Fiber Front Splitter & Lip: channels turbulence away from the underbody for better stability.

- Front Bumper Canards & Grille Surrounds: crafted in 2×2 twill weave, enhancing airflow to intercoolers.

- Lamborghini Urus Carbon Fiber Hood: autoclave-cured, weight saving ~7 kg, heat-shielded for track use.

Side Definition

- Side Skirts & Side Blades: streamline airflow, create visual elongation of the body.

- Mirror Caps & Pillar Covers: small components, big refinement.

- Wheel Arch Flares: offer a bolder stance — gesmeed koolstof available for the Urus S and Performante.

Rear Power

- Rear Diffuser & Fins: CFD-modeled for pressure stability.

- Carbon Fiber Roof Spoiler & Trunk Spoiler: increase rear downforce with optional adjustable fins.

- Undertray & Bumper Trim: fully replaces OEM parts, bolting seamlessly to factory points.

Each surface receives UV-blanke lak, hand-polished and optionally protected with ceramic coating of PPF. Every curve catches light like muscle under skin.

The Lightweight Philosophy

In motorsport, “light” doesn’t mean fragile — it means free. Every kilogram removed changes how the Urus breathes, brakes, and turns.

We’ve seen clients who, after fitting a full carbon fiber aero kit, describe the difference in words like “tighter,” “cleaner,” and even “more honest.” Less inertia means quicker feedback through the Brembo carbon-ceramic brakes, more precise steering, and improved fuel efficiency on long runs.

De resin system epoxy we use maintains elasticity, preventing micro-cracks and pinholes that cheaper carbon develops over time. This is engineering that ages gracefully — not just a weekend showpiece.

Interior — Precision Meets Emotion

Inside, the Urus already feels like a jet cockpit. Our carbon fiber interior trim kit turns that sensation into reality.

Dashboard & Console

The center console and air-vent frames are sculpted from prepreg koolstof, sanded, coated, and finished in matte or gloss. The weave alignment flows continuously from dash to door — a detail only visible when you look closely, but unforgettable once noticed.

Doors & Touchpoints

Door handles, window switches, and inserts are replaced with lightweight dry carbon trims, fitted with OEM tabs and 3M lijm. Each component is tested for NVH (Noise, Vibration, Harshness) compliance — a quiet cabin that still whispers performance.

Seats & Controls

- Rugleuningen in carbon with laser-engraved Lamborghini logo.

- Steering wheel trims met red stitching and Alcantara accents.

- Carbon fiber paddle shifters milled to precise tactile resistance.

It’s an interior that rewards touch as much as sight — the kind of luxury that doesn’t scream, it hums.

Pop the hood and you’ll see where engineering and artistry fuse. The motordeksel van koolstofvezel frames the V8 like a sculpture. Each rib is CNC-cut, resin-balanced, and heat-shielded.

Pair it with Akrapovic of Capristo titanium exhausts with carbon tips, and you reduce backpressure while gaining a sound that resonates through carbon’s natural resonance frequency — a deep, dry roar rather than metallic shriek.

Optional upgrades include:

- Carbon fiber air duct covers

- Grille surrounds and strut covers

- Urus carbon fiber fuel cap

Everything is functional, nothing superfluous.

Compatibility & Fitment

Our kits cover all major variants:

- Lamborghini Urus (2018–2021)

- Urus Performante (2022–2024)

- Urus S (2023 onwards)

Each piece follows OEM scan data. Fitment is opschroefbaar, drill-free, En radar-compatible. Whether you’re pairing with Vossen of HRE wheels, or running Pirelli P Zero tires, the alignment remains factory-true.

If you’re planning a wider bespoke build, our aangepaste koolstofvezel programs can match weave, tint, and finish across exterior and interior components for a cohesive theme.

Technical Foundation

| Parameter | Specificatie |

|---|

| Material Source | Toray T700 / Hexcel / Mitsubishi Chemical Prepreg |

| Proces | Autoclave curing 6 bar @ 120 °C |

| Weave Styles | 2×2 Twill, Plain, Forged Carbon |

| Oppervlakteafwerking | Gloss / Matte / Satin with UV Clear Coat |

| Hechting | Loctite bonding + 3M industrial tape |

| Quality Certification | ISO 9001, TÜV, ABE, E-mark |

| Durability Tests | Thermal Cycle (–40 °C to 120 °C), UV 500 h |

| Average Weight Saving | 30–45 kg (Full Kit) |

This is not a factory replica. It’s a factory evolution. For the people and process behind the parts, meet our aangepaste composietfabriek team and facilities.

Installation, Care & Customization

Every kit ships with a detailed fitment guide and installation map. If you prefer professional mounting, our network of partners in Europe, North America, and the Middle East can assist.

Options available:

- Gloss / Matte / Forged finishes

- Logo engraving and custom tint resin

- Ceramic coating, UV-shielding, and PPF application

For maintenance: Use a pH-neutral shampoo, microfiber cloth, and reapply ceramic every six months. Properly maintained, prepreg koolstof will resist UV yellowing, stone chips, En resin fade jarenlang.

Global Craftsmanship, Global Reach

From our autoclave centers in Suzhou, Zhenjiang, En Jinjiang, each Urus kit is born from controlled precision — then shipped worldwide in layered EPE + foam + wooden crate packaging.

We partner with tuners and resellers globally, supplying consistent OEM-fit carbon fiber replacement panels for every major model. Whether you’re in Dubai, Los Angeles, of Zurich, we deliver the same promise: craftsmanship that honors the Lamborghini name.

Verzending: DHL / FedEx / Air / Sea Doorlooptijd: 10–15 days production + 3–7 days transit Warranty: 12 months against manufacturing defects

When your shipment arrives, you’re not just receiving parts. You’re receiving a statement — engineered beauty, delivered.

If you’re comparing platforms and case studies, start with our landing hub for fabrikant van koolstofcomposiet expertise.

You May Also Like

- Lamborghini Urus Forged Carbon Full Body Kit

- Urus Interior Carbon Trim Set

- Urus Engine Bay & Titanium Exhaust Upgrade

- Urus Performante Carbon Aero Kit (2024 Edition)

Each set shares the same DNA: Toray T700 prepreg, autoclave curing, human touch.

FAQ — Real Questions, Honest Answers

Q: Does it fit my 2023 Urus S or Performante? Absolutely. All molds are scanned from OEM 3D data; mounting points are identical.

Q: Is it forged carbon or twill weave? Both — choose gesmeed for a bold, modern aesthetic or 2×2 twill for the classic Lamborghini texture.

Q: Will the carbon yellow under sunlight? No. We use UV-resistant epoxy with clear coat and optional ceramic protection.

Q: How hard is installation? De meeste onderdelen zijn opschroefbaar of 3M tape-on; no drilling or trimming.

Q: Can you produce custom logo or color tint? Yes — transparent red, blue, or gold tints are available for bespoke projects.

Request Your Personal Quotation

Tell us about your vehicle: Model / Year / Variant

Selecteer je afwerking: Gloss | Matte | Forged | Custom Tint

Shipping preference: DHL / FedEx / Sea Freight

A specialist will respond within 24 hours with renderings, pricing, and estimated lead times.