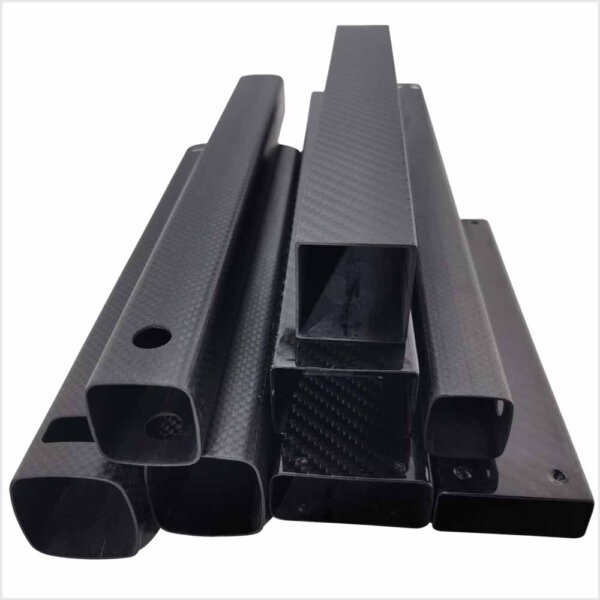

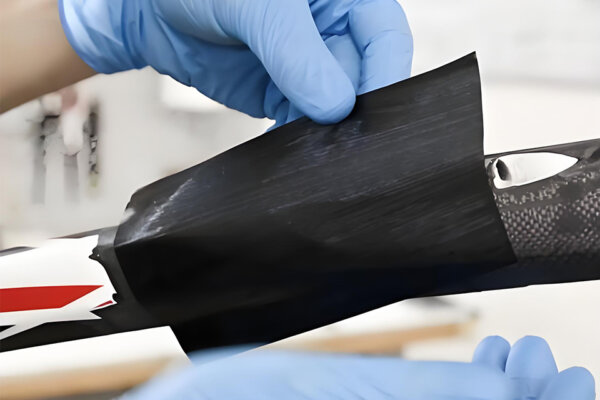

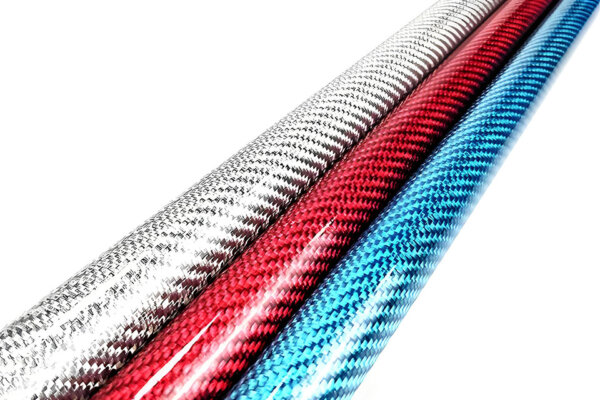

Процесс горячего прессования композитного материала из углеродного волокна

На нашем заводе применяется передовой процесс горячего прессования углеродного волокна с использованием стальной формы P20, что обеспечивает высокую эффективность, точность, долговечность и экономичность качественного производства.