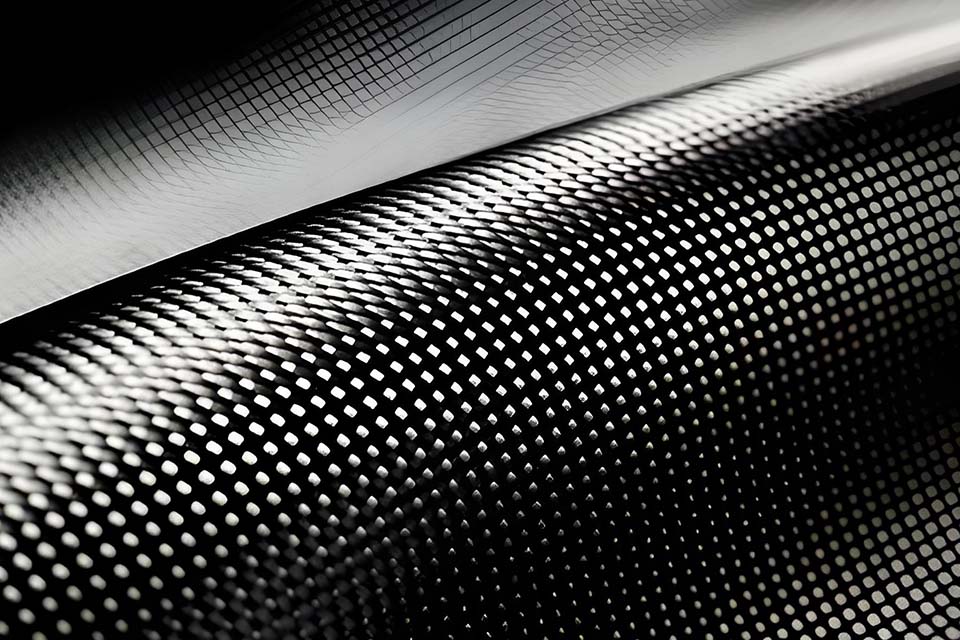

How to Cut Carbon Fiber: Easy Guide

Got carbon fiber to cut? You need the right tools. Lots of people break their carbon fiber. They try to cut with the wrong tools. This is bad for your project.

The Problem: Cutting Carbon Fiber is Hard

Carbon fiber is tough. It needs special care. When you cut it wrong:

- The edges get rough

- The fiber frays

- You get dust that is bad to breathe

- Your tools get worn out fast

Let me tell you about a customer who had to throw away $3,000 of carbon fiber parts. Why? He used the wrong cutting tools. Using resin can help prevent delamination in carbon fiber structures. The parts all cracked.

Does this sound like your problem?

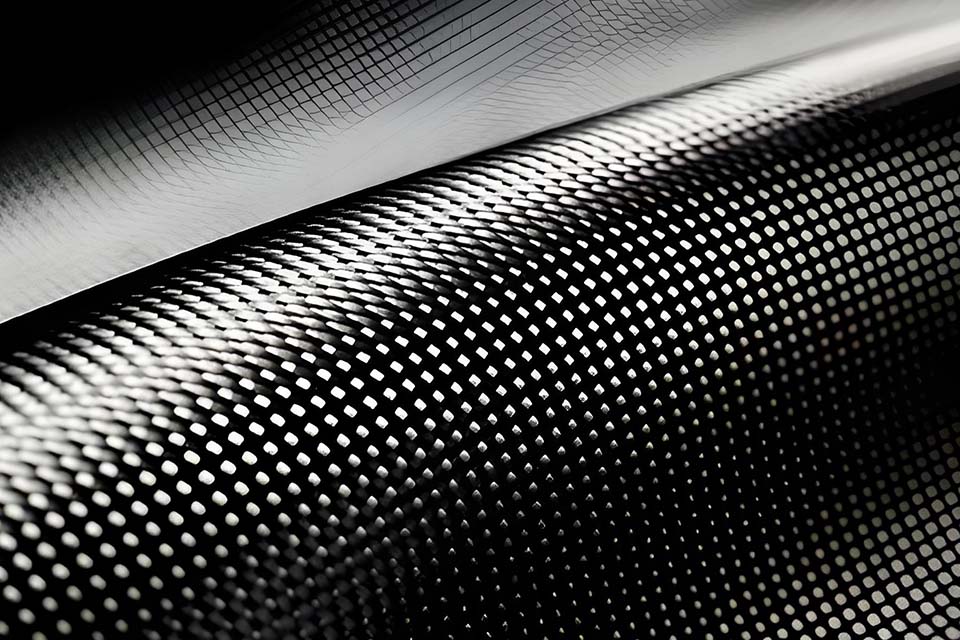

Why Cutting Carbon Fiber Scares People

When you use bad tools, these things happen:

- Your carbon fiber splits and cracks

- The dust gets in your lungs

- You waste lots of money on broken parts

- Your tools break after just a few cuts

- The edges look bad on your final product

Our team at Scomp Carbon Fiber has seen these problems for 28+ years. One car maker lost a whole race when their carbon fiber parts broke. Why? They were cut with the wrong tools.

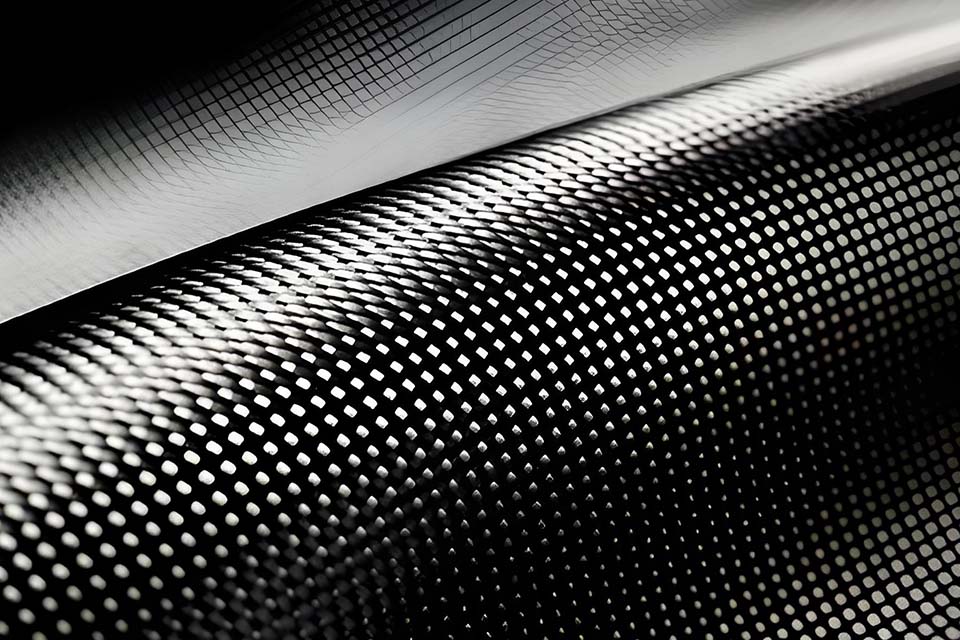

The Solution: Best Ways to Cut Carbon Fiber

With 28+ years making carbon fiber parts, we know the best ways to cut. Here are the top tools and how they work:

| Tool | Best For | How Well It Works | Cost |

|---|

| Waterjet | Big sheets | ★★★★★ | $$$$$ |

| CNC Machine | Complex parts | ★★★★★ | $$$$ |

| Blue Laser | Thin sheets | ★★★★★ | $$$$ |

| Jigsaw (special blade) | DIY projects | ★★★☆☆ | $$ |

| Diamond Tools | Small fixes | ★★★☆☆ | $$ |

| Hacksaw | Quick cuts | ★★☆☆☆ | $ |

Now let’s look at each tool in more detail.

1. Waterjet Cutting – Best for Big Jobs

Waterjet cutting uses high-pressure water with tiny bits to cut carbon fiber.

Why It’s Good:

- Cuts with no heat

- Makes clean edges

- Works on thick sheets

- 99% accurate

How to Use It:

- Put your carbon fiber on the waterjet table

- Set the water pressure (60,000-90,000 PSI)

- Let the machine cut the shape

- No dust problems!

Our custom CNC carbon fiber service uses top waterjet machines to make perfect parts.

2. CNC Machines – For Perfect Shapes

CNC machines use special bits to cut carbon fiber into exact shapes.

Why It’s Good:

- Makes complex shapes

- Very precise cuts

- Can cut many parts the same way

- Works for car parts and bike parts

How to Use It:

- Put a 1/8″ carbide downcut bit in your CNC

- Set speed to 10,000 RPM

- Use 60-75 IPM feed rate for thin sheets

- Let the machine cut the shape

See our carbon fiber car parts made with perfect CNC cuts.

3. Blue Laser Heads – For Thin Materials

Blue lasers cut carbon fiber with light!

Why It’s Good:

- Makes tiny cuts

- Very clean edges

- No tool wear

- 50% less work after cutting

How to Use It:

- Set the laser power

- Focus the beam

- Let it cut with no touching

4. Special Jigsaws – For DIY Projects

Special jigsaws with carbon fiber blades work well for small jobs.

Why It’s Good:

- Low cost

- Easy to use at home

- Good for curved cuts

- Bosch blades last 10x longer

How to Use It:

- Put in a carbon fiber blade

- Cut slowly

- Use a vacuum to catch dust

- Wear a mask

Diamond tools are good for small cuts and fixing edges.

Why It’s Good:

- Lasts long

- Cuts 80% faster than normal tools

- Good for small fixes

- Won’t break the fibers

How to Use It:

- Put the diamond bit in your tool

- Make short cuts

- Go slow and steady

6. Hacksaws – Quick and Simple

Hacksaws work for fast cuts when looks don’t matter.

Why It’s Good:

- Very cheap

- Easy to find

- No power needed

How to Use It:

- Get a fine-tooth blade

- Cut slowly

- Know the blade will wear out fast

Safety First! Protect Yourself

Carbon fiber dust is bad for your lungs. Always:

- Wear a mask

- Use eye protection

- Have good air flow

- Use a vacuum when cutting

- Wear gloves

The Advantage

As a carbon fiber maker for 28+ years, we know how to cut carbon fiber right. We are a composite material known for its strength. Our custom carbon fiber service gives you:

- Perfect cuts every time

- No waste of your money

- Fast work with top tools

- Clean edges that look good

- Any shape you need

Real Results: Case Studies

Case Study 1: Race Car Team

A race team needed carbon fiber parts that were light but strong. Their old parts were cracking. We used our CNC and waterjet systems to make parts that were 30% stronger. They won their race!

Case Study 2: Motorcycle Builder

A custom bike builder needed carbon fiber parts with complex shapes. We used our blue laser system to cut parts with perfect edges. His bikes now sell for $5,000 more with our carbon fiber motorcycle parts.

Case Study 3: Drone Maker

A drone company needed light parts that were exact sizes. Our waterjet system cut parts with 0.1mm precision. Their drones now fly 20% longer on one charge.

How to Work With Us

Want perfect carbon fiber parts? Here’s how:

- Send us your design

- We check it and give a price

- We cut it with the best tools

- You get perfect parts

Questions People Ask

Can I cut carbon fiber at home?

Yes, but you need special tools. A jigsaw with a carbon fiber blade works for simple cuts. Always wear a mask.

For factories, a waterjet or CNC machine is best. For home use, a special jigsaw or diamond tool works well.

No. Regular tools get dull fast and make bad cuts. You need special carbon fiber tools.

How much does professional carbon fiber cutting cost?

It depends on the size and shape. Small parts start at $50. Big complex parts can be $500+.

Ready for Perfect Carbon Fiber Parts?

Don’t let bad cuts ruin your carbon fiber project. With our 28+ years of experience, we make cutting carbon fiber easy and perfect.

Visit Our Carbon Fiber today to see how we can help with your carbon fiber needs.