The Start of Carbon Fiber

Did you know that carbon fiber has been around for a very long time? It all began back in 1860. A man named Sir Joseph Wilson Swan made the first carbon fiber. He wanted to use it for light bulbs.

But the real story of carbon fiber as we know it today started in 1964. That’s when two smart people, Bacon and Wesley Schalamon, made the first strong carbon fibers. They used a new way called “hot-stretching.”

The Problem: Why Other Materials Fall Short

Many parts break too fast. Metal parts rust. Plastic parts crack. Wood parts rot. These problems cost you money and time.

Parts are too heavy. Heavy parts make cars and planes use more gas. They make sports gear hard to use. They make boats go slow.

Parts don’t look good. Old materials get dull and worn. They don’t have that wow look that makes people stop and stare.

Does this sound like what you deal with? You are not alone.

Why These Problems Hurt Your Business

Think about what happens when parts fail:

- Your customers get mad

- You lose money

- Your brand looks bad

- You fall behind other companies

Every day you use old materials is a day you risk these bad things. And the world is not waiting for you.

The Carbon Fiber Answer

Carbon fiber fixes these problems. It is:

- 5 times stronger than steel

- 2 times stiffer than steel

- 5 times lighter than steel

This is why top companies like Boeing use carbon fiber for their planes. The Boeing 787 Dreamliner has carbon fiber in its body and wings. This makes the plane use less gas and fly farther.

Why Choose Our Carbon Fiber Products

We are not new to this game. For 28+ years, we have made top carbon fiber parts in China. We know how to make parts that:

- Last a long time

- Look amazing

- Work better than old materials

- Cost less in the long run

Our Carbon Fiber Timeline

| Year | What We Did |

|---|

| 1995 | Started our carbon fiber company |

| 2000 | Made our first carbon fiber car parts |

| 2010 | Added carbon fiber motorcycle parts to our line |

| 2015 | Started our custom design service |

| 2023 | Began using new eco-friendly carbon fiber methods |

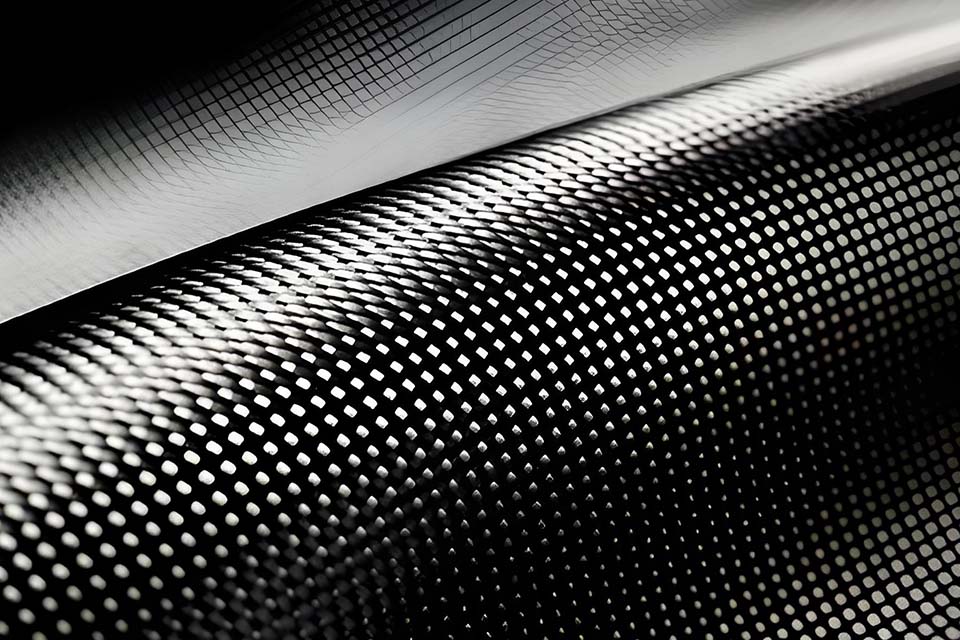

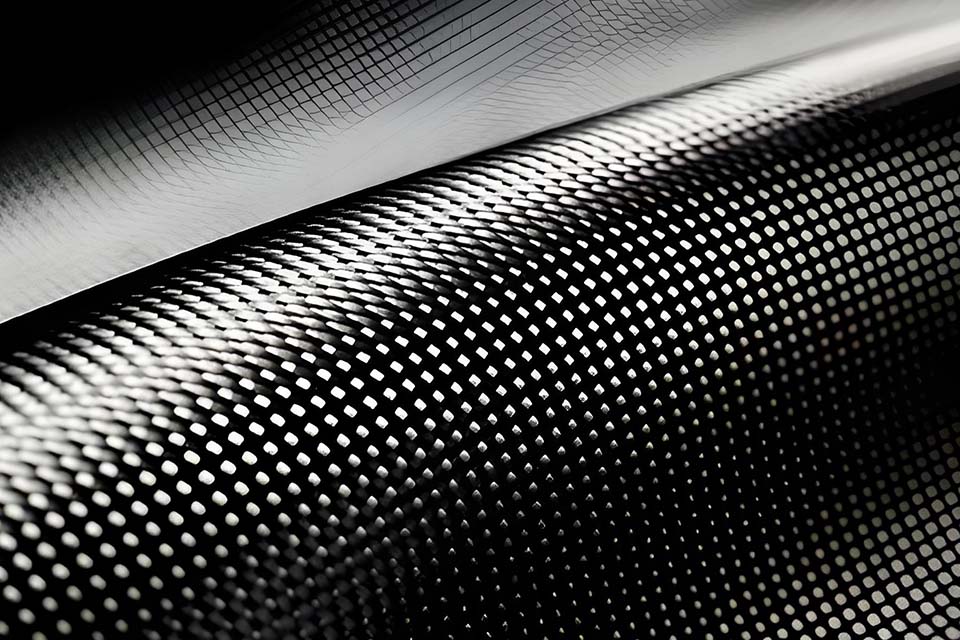

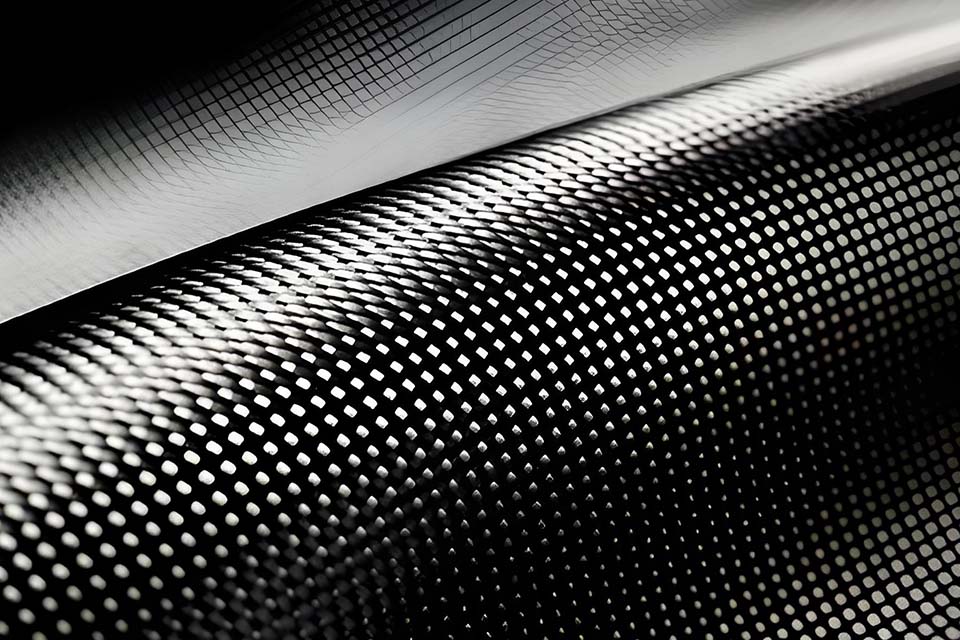

Types of Carbon Fiber We Use

We use many kinds of carbon fiber to make the best parts:

- Standard Modulus – Good for most parts

- Intermediate Modulus – Better for parts that need to be stronger

- High Modulus – Best for parts that need to be very very strong

- Ultra-High Modulus – The strongest type we have

What We Can Make For You

Our team can make almost any carbon fiber part you can think of:

Car Parts:

- Hoods

- Spoilers

- Dash parts

- Door panels

Motorcycle Parts:

- Gas tanks

- Side covers

- Seats

- Fenders

Sports Gear:

- Bike frames

- Golf clubs

- Tennis rackets

- Skis

Boat Parts:

How We Make Carbon Fiber Parts

Making carbon fiber parts takes skill. Here is how we do it:

- Design – We draw the part on a computer

- Make a Mold – We make a mold from the design

- Cut Carbon Fiber – We cut the carbon fiber to fit the mold

- Add Resin – We add special glue called resin

- Press and Cure – We press it all and let it get hard

- Finish – We sand and polish to make it look nice

Why People Trust Us

Our customers come back to us again and again because:

- We make parts that fit right the first time

- We ship on time, every time

- We check each part to make sure it’s perfect

- We use the best materials

- We have fair prices

The Future of Carbon Fiber

Carbon fiber is not just for today. It’s for the future too.

In 2025, new ways to make carbon fiber will come out. These ways will:

- Use less power

- Cost less money

- Be better for the earth

Some new ways use plant parts like lignin instead of oil. This is good for the earth and makes carbon fiber even better.

What Our Customers Say

“The carbon fiber parts from this company made my car 200 pounds lighter. Now it’s faster and uses less gas.” – Tom, Race Car Builder

“We tried three other companies before finding this one. Their parts fit perfect every time.” – Jane, Motorcycle Shop Owner

“Our bikes with their carbon fiber frames sell out as soon as we get them. People love how they look and how light they are.” – Mike, Bike Shop Owner

When you need parts that no one else has, we can help. Our custom service lets you:

- Get parts that fit just right

- Stand out from others

- Solve special problems

- Make your brand look high-end

We work with you from start to end to make sure you get just what you need.

How to Order From Us

Getting carbon fiber parts from us is easy:

- Send us your idea – A drawing, photo, or just tell us what you need

- Get a quote – We tell you the cost and time

- Approve the design – We show you what we’ll make

- We make it – Our team makes your parts with care

- We ship it – We send your parts fast and safe

Start Your Carbon Fiber Project Today

Don’t keep using old materials that break, rust, and look bad. Don’t keep losing time and money on parts that don’t work right.

Join the top companies who use carbon fiber to make their products better. With our 28+ years of skill, we can help you make parts that:

- Last longer

- Look better

- Work better

- Weigh less

Visit our main carbon fiber site to see what we can do, or call us at +86-136 2619 1009 to talk about your project.

Let’s make something great together!